From seawater to drinking water: Seawater desalination alleviates water shortage in Algeria

In view of increasing water scarcity, all approaches have to be taken into consideration when it comes to ensure a drinking water supply for the future. One method to ensure this is by desalination where seawater is turned into drinking water. Algeria is a good case of this, as new desalination plants are being established in the country.

Water shortage is an especially serious matter in certain regions of the world. Many African countries suffer from a shortage of water. Algeria is an example of such a country that faces structural water shortages. However, there is a solution to this and desalination has the potential to contribute to the alleviation of global water scarcity with theoretically unlimited water resources.

Water resources in Algeria

Algeria is one of the countries in the world with water resources that are well below the threshold adopted by the World Bank. The situation is caused by many factors, such as:

• Spatial distribution of the water

• Seasonal and inter-annual irregularities of the rainfall, filling up the reservoirs with sediment

• Vast losses of water due to the aging of the municipal distribution networks (up to 40% of the water is lost in the distribution system)

• Pollution

• Insufficient infrastructure

• Lack of maintenance

In order to alleviate the water problems, Algeria started investing in desalination plants during the sixties. As a matter of fact, Algeria has significant indigenous energy resources and has been involved in desalination for many years for industrial use mainly in connection with the development of oil and gas projects.

Because of this history, Algeria is actually on the forefront of desalination compared to many other countries in the region. In other countries the issue of water shortage is often handled quite differently using methods that only ensure water in the short term.

Providing water in the short-run

There are different methods to secure water supply -- however it is worth noting that many of these are short-term measures. Some of these are listed below.

One method to secure water is to use surface water, such as lakes and rives. The demand for domestic agricultural and industrial water is generally met through developing surface water sources or through pumping of groundwater. Regarding the water from lakes and rivers, this is only a temporary solution and thus not accessible for the longer term.

In some cases such as in Algeria, it is very cost intensive to pump groundwater. You have to drill and pump for more than 2 kilometers before you reach the ground water which makes this very cost- and resource-intensive. Thus, this is not a durable solution in the long term.

Another method that can be applied is intervention, for example by the government. Once conventional water resources become scarcer or too expensive to develop further, governments can turn their attention to restrict water demands or to more effectively use the existing resources. This is also a short-term option and not beneficial for the population.

Based on the above-mentioned methods it can be claimed that in the short run desalination is not a considered method as it is thought of as expensive and resource demanding. This however is not the case in the long run. Thus, desalinated water is often the last resort for countries to overcome water shortages.

Desalination as the long-run solution

Based on the above arguments, it is clear that there is a need to ensure drinking water not only in the short term but definitely also for the longer term. Desalination is a vital method in this context as it can theoretically provide unlimited amounts of fresh and clean drinking water.

Desalination technology itself has evolved substantially, making it significantly cheaper, more reliable, less energy-intensive and more environmentally friendly than it was just a few decades ago. This leaves the field of desalination open to be explored in the future.

Desalination techniques are applied to water from a wide variety of sources. In addition to seawater, desalination can be applied to brackish water, river water, wastewater, and even treated water from municipal supplies. However, in this article only the application of seawater will be investigated.

Seawater can be categorized as either surface intakes where water is collected above the seabed or subsurface intakes. Intake designs must ensure that the supply of raw feed water to the desalination plant meets the maximum flow demand in all seasons.

Desalinated water is free from pathogens and constitutes a safe source of drinking water in terms of microbes. However, desalinated water from plants using distillation technologies is completely de-mineralized and needs to be re-mineralized before human consumption in order to include minerals that are essential for human nutrition.

Vitality of flowmeters

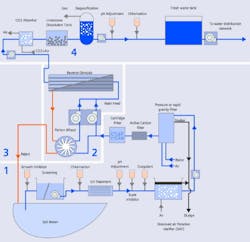

Flowmeters are vital process equipment and are therefore also applied at different stages in the desalination process. Within the process of desalination, flow meters are placed in strategically important locations, enabling enhanced procedure control, automation and efficiency.

First of all, a flowmeter is installed in order to measure the overall inlet of the seawater. At this stage, the seawater contains different kinds of particles, sand, fishes, stones, etc. These different particles are then separated from the seawater, thereafter the water is again measured. This stage of the process is named the "raw water intake." Following this process, different chemicals are added such as chlorine along with pH adjustment remedies.

Later in the desalination process, other flowmeter installations are applied for vital purposes before the seawater ends up as drinking water. However, these processes will not be elaborated further in this article.

Installation in Algeria

Algeria has recently enhanced the countries desalination plants, with the addition of three plants. Siemens flowmeters are used in these installations -- with the installation of the Sitrans F M MAG 3100 sensor and the Sitrans F M MAG 6000I transmitter.

For the specific customer in Algeria it was important that the flowmeters enable certain features such as:

• Availability in large DN sizes

• Robust materials for the liner and electrode materials

• Capable of handling high pressure

• Encompass the needed drinking water approvals

Turning seawater into drinking water requires large amounts of water. In order to measure the flow, it is thus important that the flowmeter comes in large DN sizes. In this specific application the sensor sizes are up to DN 1800 which is required because of the large flow to be measured.

As explained earlier, the seawater contains many different types of particle, which makes the environment harsh. Thus, the material of the flowmeter must be robust. Especially the choice of liner and electrode material is essential because of the salt that affects the flowmeter sensor. For the customer it was important that the flowmeter was available in a vide variety of materials. Namely the EPDM liner and the tantalum electrode which were also chosen by the customer.

In order to measure the flow in the "filter stack process," the flowmeter must be able to handle up to 100 barg. This stage in the process is especially critical as it can block the reverse osmosis, which is the next stage in the desalination process. The flowmeter that has been installed in Algeria encompasses a pressure range from PN 6 to PN 100. On request, the Sitrans F M MAG 3100 can be ordered for up to 690 barg (10.000psi).

The final feature of the flowmeter that was specified for the installations in Algeria was the amount of approvals. In order for seawater to end up as drinking water, it is necessary that the flowmeter encompasses the needed drinking water certificates. An example of such a certificate is the OIML certificate (International Organization of Legal Metrology), which guarantees that the water can be approved as drinking water.

Conclusion

Throughout the article, it has been proposed that desalination can be the solution to the global problem of water shortage. Indeed, desalination is an excellent method that can guarantee water supply for the long term. This is namely the case in Algeria, which faces serious problems with water shortage. It has been highlighted that flowmeters play a vital role in the process of desalination, and the installations in Algeria are a good example of this.

However, it must be highlighted that desalination alone cannot deliver the promise of improved water supply. It must be mentioned that establishing desalination plants is not as easy as 1-2-3. The ability to make the best use of desalination is subject to a series of wider water sector related conditions. Factors such as weak water utilities, politically determined low water tariffs, high water losses and poor sector policies affect how desalinated water may not be used wisely or that desalination plants are at risk of falling into disrepair. Thus, it is not just about the desalination plant in itself, but also other factors that must be taken into account.

About the Author: Marco A.A. Camarena is product manager for Sitrans F M in the Siemens Flow Instruments unit of Siemens AG in Nordborg, Denmark. Contact: www.siemens.com/flow

August 2009

###