Water Technology Innovation Q&A

A Look Forward with Bentley’s Robert Mankowski

Robert Mankowski leads the development team responsible for Bentley's AssetWise capabilities and services. With over 20 years of experience in software development and seven patented technologies under his belt, he offers his insights into the future of water utility data management.

WATERWORLD: Being mostly buried and therefore out of sight, water/wastewater network assets are subject to being out of mind, making it difficult to know what you own, where it is located, what condition it is in, and how well it is performing. What is coming to make it easier for utilities to ensure a safe and reliable operation?

ROBERT MANKOWSKI: In recent years, there have been significant strides in GIS-based workflows between the field and office. The industry is doing a much better job of accurately capturing as-builts and keeping the GIS up to date with what is in the field. There is also some compelling research and several innovations driven by the academic world through projects such as Mapping the Underworld that focus on understanding where our underground assets are. Applications like Bentley's Subsurface Utility Engineering help mitigate the risk of building in a utility-congested underground environment. It provides users the capability to generate, visualize, and analyze 3D models from survey information, CAD artifacts, GIS, Excel spreadsheets, databases, and more. The application follows standards such as ASCE 38-02 in the U.S. and PAS128 in the U.K., which provide a means to capture the quality level or accuracy of the source information used to create the models. However, water and wastewater networks remain particularly challenging because they are typically buried underground assets that impact many people when they fail. It is essential to better understand the condition of the assets, the probability of failure, and the consequences of such failures.

We also need to understand the provenance and history of what's happened with the networks. This is especially important for capital improvement programs and capital investment planning -- to decide how to invest to have the safest and most reliable operation. Utilities need a lot of information to determine which pipes are more likely to fail, what happens when such a failure occurs, and the capabilities to efficiently manage and analyze it to support decisions.

Utilities need to manage and maintain a geospatial asset register of all water and wastewater network assets to which they may associate a wide variety of inspections and surveys. This provides a detailed and data-rich view of the "as-maintained/as-operated" condition status of the network, as well as preserving historic records of condition assessment that can contribute to a better understanding of asset failure modes and causes.

Asset inspections and surveys provide dual roles -- asset discovery and asset condition assessment. Inspections and surveys can be used to update the asset's physical, location, and condition information held in the asset register, as well as create new assets that were previously unknown. All associated inspection metadata, data files, databases, photographs, time series (e.g., flow or pressure monitors), and video (such as CCTV) should be managed and associated with the relevant asset. This provides an "asset-centric" view of the inspection and survey data collected for asset update or asset discovery. Capabilities, such as those available with Bentley's AssetWise, can work in concert with a geospatial information system to provide these capabilities and allow utilities to plan and implement proactive asset performance and reliability strategies.

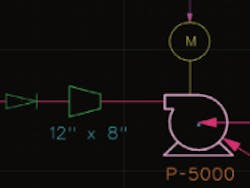

Hydraulic modeling applications, such as Bentley's WaterGEMS, also play a role in ensuring safe and reliable operations by forecasting system conditions and performance, managing pumps and storage, planning for scheduled maintenance, and helping operators react to unplanned outages and emergencies. Advanced analytics can help you fill in the gaps between the locations and times that SCADA systems and other data collectors use to gather information. This allows operators to detect and troubleshoot problems as soon as they arise, leveraging knowledge in the control room to help guide field crews to the right areas to investigate and act.

WW: What benefits does a digital strategy provide water and wastewater utilities?

RM: Going digital is a strategy that we at Bentley believe will transform the delivery of capital projects as well as the performance of assets in operations and maintenance. By digitizing assets and processes, a digital strategy will not only realize performance improvements for assets but also see the adoption of new technologies that can enable going digital. This strategy might suggest adopting a cloud services platform as an example of going digital to increase collaboration, security, and scalability by staying connected. For water and wastewater utilities, it means they have an opportunity to improve their business processes. For example, an owner-operator might want all stakeholders to have visibility for distributed teams working on a single project or multiple projects. A going-digital strategy connects and converges to ensure information is managed effectively to reduce errors, inaccuracy, and improve performance.

This of course is a high-level approach but nonetheless highlights the potential as we see it. Bentley is also committed to enabling our users to implement a BIM methodology as a strategy for better collaborative design and to enable ongoing maintenance and operations. The work done by engineers in the early phase of a project is critical for all phases of the lifecycle, and the digital engineering models produced in design can serve as the fulcrum for performance improvements.

The goal for most utilities is indeed reducing TOTEX (total expenditure inclusive of CAPEX and OPEX), and technology is the enabler. As head of development for our asset performance team I am in a nice position to see the benefits realized by our users. We live vicariously through our users who continue to amaze us with innovation and expertise in utilizing our software. But it is our job to continue providing the right technology and platforms so that the going digital strategy can deliver the right results.

WW: Bob, you wrote some of the code for the very first iteration of WaterCAD in the 90s. What sorts of changes have you seen in the industry -- and in user experience -- in the years since?

RM: That's a multi-faceted question because so many changes have occurred in the 20+ years since we released WaterCAD v1.0. Let's start with the user experience changes. Before WaterCAD, the most widely used hydraulic modeling software ran on DOS. WaterCAD was the first mainstream Windows stand-alone hydraulic modeling package. That was a huge and very welcome change for users. At that time, hydraulic modeling was not as widely used as it is today, and it was mainly used for system master planning. Now, it's a very mature practice in water utilities, and is used for a range of applications, including master planning, water quality studies, energy studies and optimization, and real-time operational decision support.

The computing power available at the time was mainly based on 486s, with maybe a few users of the earliest Pentium chips, and system memory, RAM, was expensive and therefore limited. This constrained the size of the models that could be analyzed. Now, of course, we have high-powered, multi-core CPUs and GPUs with gigabytes of memory in our laptops and workstations so we're at a point where it's not only feasible but in some ways easier to model every pipe and appurtenance in the system. The algorithms can take advantage of the multiple cores -- in a fire flow analysis, for example -- to run simulations in parallel and greatly reduce the time it takes to analyze large systems. And, the graphics power of the GPUs makes it easy to create great visualizations of the data so engineers don't have to pore over tables of data but can see it in graphs and maps and in some cases in 3D.

And, I'd say it's easier in some ways because the implementation of GIS has really come a long way in 20 years, so we can build hydraulic models from that geospatial source data. In the 90s it was common to digitize the hydraulic models from scratch, and this was a time-consuming and error-prone process. I remember it was 1998 when I wrote the first shapefile import routine for WaterCAD, and it really changed the way hydraulic models were created and maintained. Today, not only do we intra-operate with GIS, WaterGEMS users can actually work in the GIS environment.

WW: How does Bentley software align with good engineering practices in water and wastewater systems?

RM: Bentley Systems has been supporting infrastructure engineering best practices for 30+ years. MicroStation is our flagship modeling application and is used around the globe for modeling, documentation and visualizing projects of all sizes and complexities. So, engineering is in our DNA and this permeates through development teams and applications to maintain the standards set by such applications. For water and wastewater, the principles are no different. By advancing the entire network lifecycle -- from treatment plant design to the planning, design and operations and maintenance of networks -- our software is reflective of engineering precision and accuracy.

Bentley's Haestad applications are engineering-ready decision support software for water professionals who design, plan, and operate water distribution systems or for urban sewer planners who also want to analyze and design sanitary or combined conveyance sewer systems. These applications can operate in stand-alone mode with MicroStation, AutoCAD, or ArcGIS and incorporate various other file formats. We've been supporting engineering best practices for many years and we intend to continue to advance our software and services to meet this demand.

WW: Information systems in a water/wastewater utility can be highly distributed (or siloed). How can utility stakeholders address this problem to improve decision making?

RM: Information can be very siloed, and it takes a significant change in an organization to adopt new processes. It is, however, a rather simple equation. Why wouldn't any organization want engineering information that is relevant, accurate and accessible to all project participants? The question has always been put to us; how can we improve decision making based on the data available?

The answer is quite simple. Having a common modeling environment helps speed design and improves collaboration. Having a common data environment helps streamline design and management of critical information, but the key is now a connected data environment that helps facilitate the interoperation of multiple data sources, providing a common view of data that delivers accurate and reliable information to operations, maintenance, and engineering when it is needed.

WW: What does the future hold for the water industry in terms of how IoT, Big Data and other trends will impact the sector?

RM: Sensors will play an even larger role in network modeling and operations. By providing real-time information that can be supplemented with hydraulic models, the operator can have true insight into the behavior and condition of a network. This provides more options for the hydraulic modeler in the calibration and modeling processes when different scenarios provide different results and benefits. It provides the operator with a more comprehensive operating picture of the network than SCADA data alone, even forecasting how the system will behave in the immediate future.

Big Data also provides big challenges but at the same time, provides significant opportunities. As operational technology (OT) leverages the Industrial Internet of Things (IIoT) with operating systems and sensors to produce huge quantities of data, the need to make this data usable and secure is fast becoming mainstream in its outreach and adoption. So far, OT data has initiated a convergence with IT systems, which has yet to yield significant gains. At Bentley, we see the critical importance of also leveraging the engineering technology (ET) data to realize those gains.

Asset information management systems that enable the convergence of IT, OT, and ET data will make infrastructure assets more powerful, efficient, and reliable by exploiting the Big Data potential. Using cloud services platforms, digital engineering capabilities will go beyond observing and monitoring the asset's performance to modeling its desired behavior to produce better outcomes.

Water and wastewater utilities have been a step ahead of other industries in exploiting the potential for ET and OT data to be better utilized. IIoT and supervisory control and data acquisition (SCADA) systems have had a harmonic convergence of their own in enriching the oversight value of data analytics for treatment, distribution, and collection facilities. Engineering departments and the operational control rooms have more reason to interact than ever before, as the common goal of ensuring reliable service, reducing cost and optimizing their networks can be realized -- in real time. Hydraulic modeling generally has been used for long-term planning, while data from the SCADA systems are used heavily in daily operational decisions. Linking these two technologies has ensured barriers are removed, collaboration improved, and data shared for mutually beneficial reasons.

WW: What is Bentley focused on from an R&D perspective?

RM: While we undertake R&D across a broad range of technologies and disciplines, perhaps the best answer here is simply the overarching principle. Bentley is focused on making our users productive and successful while advancing infrastructure.