Impact of Cavitation, Air on Centrifugal Pump Performance

By Allan R. Budris

There are many misunderstandings about air, cavitation, cavitation noise, and the potential of cavitation damage in centrifugal pumps. They include such misconceptions as:

- There is no cavitation in a pump if the NPSH available to the pump exceeds the NPSH required by the pump (even if the margin is only one foot).

- Entrained air will always make a pump noisy.

- Cavitation will always cause damage and shorten pump life.

Cavitation can exist above the NPSHR (net positive suction head required) of a centrifugal pump, as stated in the writer’s October 2007 pump tips Column. The NPSHR of a pump is not the point where cavitation starts. According to the Hydraulic institute, the NPSHR of a pump is the NPSHA (net positive suction head available) that will cause the total discharge head of the pump to be reduced by three percent. This head drop is caused by flow blockage from cavitation vapor in the impeller eye. This means that there was also enough cavitation in the impeller to cause head drops at two percent and one percent as well. The three percent head drop criteria was based on the ease of determining (testing) the exact head drop-off point, and because standard low suction energy pumps can operate with little margin above the NPSHR point, without seriously affecting the operational integrity of the pump (although the head will be slightly low).

It normally takes an NPSHA of four times the NPSHR of a pump (on average) to fully suppress cavitation within a pump. It can take from 1.05 to 2.5 times the NPSHR just to achieve the 100 percent head point. The actual NPSH margin required to suppress all cavitation in a pump (the incipient cavitation point) can range from 2 to 20 times the pump NPSHR, depending on the suction energy. This is why some pumps can generate cavitation noise, even when the NPSHA of the system exceeds the NPSHR of the pump by a significant amount. Whether or not operation in this post NPSHR cavitation region will cause noise, and/or be detrimental to the life of the pump, is a dependent on the suction energy, NPSH margin, flow rate, and the air content of the liquid.

But not all cavitation, whether from higher flow, low NPSH margin conditions, or from suction recirculation, will cause damage to the pump. As spelled out in the authors October 2007 pump tips column, Low Suction Energy pumps should not experience damage from cavitation (unless abrasives or corrosives are present). High suction energy pumps will mainly cause noise, but little if any damage, especially with erosion resistant materials. But when a pump reaches Very High Suction Energy, it is normally susceptible to cavitation damage (except when a certain amount of entrained air is present).

Entrained Air

There are many differing opinions on the effects of entrained air in a centrifugal pump. Entrained air is often considered detrimental to pump performance and life. Large amounts of air (over about five to six percent) can collect in the eye of the impeller and cause loss of flow and possibly air binding. Air can increase the noise level in high (discharge) energy pumps, which have high impeller outlet tip speeds and small volute tongue clearances. However, small amounts of entrained air (below about one percent) have been seen to cushion the implosive effects of cavitation, thus reducing their noise and erosive damage.

The addition of only about ½ percent of additional air (.38 percent to .89 percent) is seen to reduce the suction pressure pulsation level (at the vane pass frequency) in a six inch inlet end suction pump by 82 percent (see Figure 1). The pressure pulsations were cased by (and are a measure of) the collapse of cavitation bubbles in the pump. Further increasing the air content (beyond about one percent), however, showed little additional reduction in the pulsation level. The author has never seen a case where entrained air made a pump noisy.

This explains several pump phenomena, such as:

Why some (normally high suction energy) pumps are quiet while handling some liquids, but noisy handling others, even at the same flow rate and NPSH Margin. Pumps handling liquids that have higher entrained air contents, such as sewage, will be quieter than when pumping plain water. So a sewage lift pump might be noisy when handling high volumes of storm water, but quiet down when higher concentrations of sewage are pumped. This noise could also be associated with cavitation damage in “Very High Suction Energy” pumps.

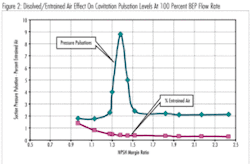

It explains why some centrifugal pumps actually get quieter as the NPSH Margin is reduced and there is more cavitation in the pump. Liquids normally have both entrained and dissolved gases such as air in them. It is only the entrained air that quiets and cushions the cavitation implosions. But as the suction pressure is reduced and more liquid flashes into cavitation vapor, more of the dissolved air is released, coming out of solution and becomes entrained. This adds to the quieting effect at low NPSH margins, see Figure 2. So, just because a pump becomes a little noisier with a small increase in the NPSH margin, does not mean that the noise is not caused by cavitation. The maximum cavitation caused pressure pulsations normally occur between NPSH margin ratios of 1.3 (around the pump BEP flow rate) to 2.3 (around the start of low flow suction recirculation). Therefore, it may take an NPSH Margin of over 2.0 to 2.5 to start to quiet (a cavitation caused) noisy pump, and reduce any erosive wear.

This also presents a possible way to quiet a cavitation caused nosy pump, and reduce any associated wear. If a small amount of air can be tolerated in the system, then by injecting a limited amount of air (not to exceed 1%) into the suction of the pump, the life of the pump may be significantly extended. WW

References: “Effects of Entrained Air, NPSH Margin, and Suction Piping on Cavitation in Centrifugal Pumps”, by Allan R. Budris & Phillip A. Mayleben, Proceedings of the 15th International Pump Users Symposium, March1998

About the Author:

Allan R. Budris, P.E., is an independent consulting engineer who specializes in training, failure analysis, troubleshooting, reliability, efficiency audits and litigation support on pumps and pumping systems. With offices in Washington, NJ, he can be contacted via e-mail at [email protected].