At the same time, water and wastewater facilities must establish a baseline of energy usage. This is accomplished with an energy audit and establishes where and how much energy a plant is using. The next step in the cycle is implementation of passive and active energy efficiency measures.

Passive energy measures are defined as items that are easy to implement without complex automation. Active energy measures require automation and optimization of processes. The last step is metering for monitoring and verification of energy usage. The metering allows a plant to benchmark energy use and establish future energy efficiency goals and key performance indicators for effectiveness of measures implemented.

Common Measures

There are a number of common energy conservation measures that can be implemented in both water and wastewater treatment facilities. For example, changing out motors with more energy efficient motors and managing HVAC and lighting loads are common energy conservation measures. In addition, implementation or upgrading an existing SCADA system to monitor and control energy usage is common to both types of facilities, as are demand monitoring, load shedding and cogeneration.

Water Treatment

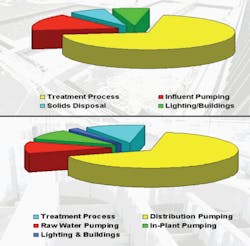

Energy management opportunities for water treatment plants are usually centered on pumping applications. National Electrical Manufacturers Association (NEMA) Premium® or Energy Policy Act (EPAct) high efficiency motors and variable frequency drive (VFD) applications are low hanging fruit to review for pumping.

Pump optimization with SCADA systems or specific pump optimization software are additional items to consider. Even proper maintenance and operation of pump systems will help in maintaining the nameplate efficiencies of the motor, pump and overall pump system.

Additional opportunities for energy management with a smaller return are heating ventilation and air conditioning (HVAC), high efficiency fixtures and lamps, as well as lighting monitoring and control. Supplying energy efficient ballasts for plant fluorescent fixtures and ultraviolet (UV) disinfection or pretreatment systems is an opportunity to reduce energy.

Although not directly related to energy, properly monitoring and controlling water treatment plant chemical feed systems can help maintain plant efficiency.

Providing storage to allow for pumping during low energy demand times for electric utilities and distributing the water by gravity during high demand times could help with obtaining incentives or reduced rates from local electric utilities.

Wastewater Treatment

The most opportunistic energy management areas for wastewater treatment plants are primarily aeration and pumping applications. This includes aeration for activated sludge and aerobic digestion as well as return and waste activated sludge pumping. Further, lift and influent pump stations and any effluent pumping requirements can provide energy savings.

As with water treatment, NEMA Premium® or EPAct high efficiency motors and variable frequency drives are low hanging fruit for better efficiency.

Dissolved Oxygen (DO) monitoring and control are critical for energy efficiency. The control of an aeration system includes adequately spaced and maintained DO sensors with properly sized blowers. The type of blower must also be evaluated for the application. For example, is the best blower a positive displacement, centrifugal with variable speed or single speed centrifugal controlled with vanes, valves or VFDs?

Pump and blower optimization are also a consideration in wastewater applications. Knowing which pumps or blowers to use at what time and maintaining control over the requirement is extremely important.

Equalization basins could also be used to assist with pumping energy requirements. This is accomplished by shifting treatment to low energy demand times to save costs. Pump and blower systems should also be evaluated to determine the best efficiency and utilization of the information to load the most efficient system at the optimum time.

Another good opportunity for energy management in wastewater is solids handling and removal. Finding applications that can dewater sludge more efficiently will reduce sludge handling costs. Also, there are many different types of systems developed or being developed to use sludge as a biofuel for cogeneration or peak shaving of demand.

The methane produced by anaerobic digestion of the sludge can be used for cogeneration or heating requirements to save energy. Flaming or flaring off the excess gas after the sludge heating process typically wastes any methane gas that could be used to produce electricity. However, when it is not used for generation of electricity or heating, flaring off the excess gas reduces GHGs.

Energy Audits

Energy audits were conducted for two wastewater treatment plants and one water treatment plant. The audits found that one of the wastewater plants had the potential to save 17% in electric cost and 7% in fuel costs. The second wastewater plant had the potential to reduce its electric energy costs by 10%. Combined, the two plants had the potential to save over 3.5 million kWh in electrical energy and reduce CO2 emissions by 4.5 million pounds.

The savings were from optimization of pumps and better control of dissolved oxygen for the activated sludge process. Other items included replacement of motors with higher efficiency motors, better sludge transportation arrangements, reduction in demand with a demand response program and renewable energy credits that helped reduce costs.

The water treatment plant audit found the potential for a 25% reduction in electric costs. Again, pump optimization, replacement of motors and installation of variable frequency drives were the major conservation measures for the plant. With those changes, the plant could reduce electrical consumption by over 11 million kWh and cut CO2 emissions by 14 million pounds.

WW

About the Author: Lee E. Ferrell is a board certified environmental engineer, a registered professional engineer in the state of South Carolina and a water and wastewater energy and process consultant for Schneider Electric. Staff from the Schneider Electric Water Wastewater Competency Center will be on-hand at WEFTEC to discuss the company's energy audit services.Schneider is an exhibitor at the WEFTEC.10 event and can be found at Booth No. 5553

More WaterWorld Current Issue Articles

More WaterWorld Archives Issue Articles