SCADA System Monitors Water Transport, Distribution, Treatment

The scenic beach town of Carlsbad, CA, just north of San Diego, is known for its beautiful beaches, upscale homes and quaint shopping district. Water purchased from the San Diego County Water Authority is distributed to businesses and residences. Delivery of the potable water requires little to no pumping, as the water travels via a gravity feed from large storage tanks.

Carlsbad’s SCADA system has been configured to control various equipment and monitor the water throughout this entire process. Analog and digital input and output modules connect to:

• Level transducers that track water levels in large reservoirs and tanks.

• Pressure transducers in pipes that measure pressure in pounds per square inch (psi) within each zone and ensure that water is pumped and is flowing efficiently as it’s being delivered.

• Flowmeters that measure how many gallons of water per minute are being delivered.

• Pressure-sustaining, pressure-reducing, and other valves that open and close incrementally to adjust the rate at which the water flows.

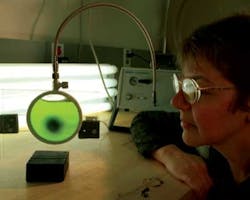

Technician Tom Pagakis oversees the SCADA systems that monitor and control all water and reclaimed water for the city. The key components for these systems are SNAP-brand controllers manufactured by Temecula, CA-based Opto 22.

“We started using Opto as an experiment,” Pagakis said. “Years ago, we were using outdated technologies like tone telemetry and later, a mix of I/O modules and systems from other vendors. Special drivers had to be created to make everything communicate and it had become very complicated and unwieldy.”

The SNAP systems — which communicate with each other and back to the control center through a combination of radio, serial, and Ethernet links — are used to monitor, control, and acquire data from all of the city’s water and reclaimed water systems. Pagakis regulates all water transport, monitors an independent water treatment plant, and controls the chemical dosing of ammonia and chlorine that cleans the water. In total, these activities incorporate more than 1000 I/O points distributed across the city’s command and control center and numerous remote sites.

“Currently, the SCADA system encompasses three large reservoir impounds, 14 reservoirs, and 20 pressure-reducing stations used to monitor more than 500 miles of distribution pipeline,” Pagakis said.

Significantly, all of the monitoring and data acquisition functions are performed not by a single (or even multiple) central controllers, but by local I/O processors (or “brains”) distributed at pump stations and other points across the city’s infrastructure. These brains communicate to I/O located on the same rack and perform functions normally reserved for an expensive PLC.

For example, the brain takes valve readings from the analog input modules and performs scaling calculations to convert a voltage measurement into a percentage. So, for a typical 4-20 mA analog input module, a measurement of 12 volts would result in a reading of 50%. To have this scaling and engineering unit conversion take place locally, at the I/O level, relieves the main controller from extra processing, while also providing control center personnel the convenience of being able to view and interpret easy-to-understand units of measure (i.e., percentages as opposed to voltages.)

Distributing intelligence in this manner also provides a safeguard in case there’s an interruption in the operation of one of the main controllers. The brain can be instructed to continue to record measurements and perform calculations, and operators can continue to view this data from the control center’s HMI.

Wonderware HMI

The Carlsbad HMI is a Wonderware InTouch system that integrated neatly with the Opto 22 hardware and allows control center personnel to view operational variables and conditions relating to pressure, flow, levels, equipment status, and more. Pagakis also uses his Wonderware system to generate bar and line graphs (indicating such things as tank levels, pump status, and valve positions) and also for performance and historical trending. For example, he generates a 24 hour trend for each storage tank, along with reports for the city on how much water that is pumped each day, week, and month.

The HMI is configured to alarm on a number of I/O point readings. By defining “normal” or “safe” operational states for specific I/O points, if conditions ever deviate from those parameters, the control center receives a visual alarm. The alarms are also integrated into a pager system and an on-call operator receives a cell phone message that they acknowledge and handle appropriately.

For example, as the control center monitors downstream and upstream water deliveries, it receives alarms on any dramatic changes in pressure due to factors such as a fire hydrant being used or damaged—something that occurred regularly when the San Diego area recently experienced a number of large wildfires.

The Opto 22-based SCADA system was also programmed to trigger an alarm when valves malfunction, or when any of the variable frequency drives that regulate any of the pumps fails.

“The VFDs we use are driving pump motors with large power loads, and these are subject to voltage spikes and unusual waveforms,” Pagakis said. “We wired up to analog inputs to continuously monitor our VFDs’ hertz and motors’ RPMs. That way, if either one of them goes, we know right away.”

Pagakis said that the strict monitoring and alarming is due in part to the city’s negotiated contract for how much water can be sourced, as well as when and how fast it can be pumped. The city is contracted for a specific seasonal amount of reclaimed water per day. Therefore, the control programs call for the controllers to shut down pumps as soon as this volume is reached. Furthermore, due to rates imposed by the local power company (San Diego Gas & Electric), the optimal time of day to pump the water is late at night. So although the system has been programmed to monitor the city’s water supply levels and begin automated pumping whenever readings drop below a certain point, a condition written into the program delays that pumping until 10:15 pm and always stops operation at 5:50 am.

Moving Forward

The Opto 22 system currently receives input signals from assorted infrared devices, motion detectors, and reed switches outfitted on door frames—all of which are used to ensure there is no unauthorized entry into lift stations, booster stations, or any other facility. Pagakis has plans to add video surveillance to these intrusion monitoring activities and is also closely tracking the development of a proposed desalinization plant that could provide an additional 50 million gallons of drinking water per day for distribution.

WW

More WaterWorld Current Issue Articles

More WaterWorld Archives Issue Articles