Power Precautions: Analyzing Pump Startup and Shutdown Best Practices

By Allan Budris

There are many important factors that should be taken into consideration during pump transient conditions, such as with pump startups and/or shutdowns. The key factors of importance during these periods are the mass of liquid in the pump piping that must be accelerated or decelerated, the pump specific speed and the pump resulting input power and head during these transition periods.

During the startup of a centrifugal pump, prior to the time that normal flow is reached, these transient conditions can generate heads and input torques (power) that are much higher than design. In some cases, the selection of the driver and the pump must be based on startup rather than on normal flow conditions.

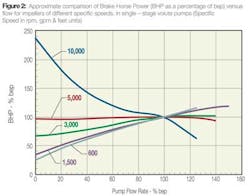

From a liquid momentum standpoint, centrifugal pumps should be started and stopped at or near the pump shut-off flow (closed valve). However, higher specific speed pumps can generate very high heads and high values of input power (torque) at or near the shut-off flow. As a result, high specific speed pumps can seldom be started or shut down at very low flow rates.

Pump Specific Speed

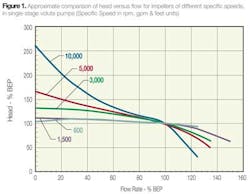

Low to medium specific speed pumps of the radial and mixed flow types (having specific speed values of less than approximately 5,000 in rpm, gpm and ft. units) have favorable startup characteristics [See WW, Sept. 2009]. Their pump heads at shut-off are not significantly higher than that at normal flow, and the shut-off torque is less than that at normal flow (see Figs. 1 and 2). On the other hand, high specific speed pumps of the mixed and axial flow types (greater than a specific speed of approximately 5,000) can develop relatively high shut-off heads, and their shut-off torque is greater than that at normal flow. This causes high-specific speed pumps to require special attention during the startup and shutdown operating periods.

Prime Pump

Although not normally an issue on systems with tight foot valves and shaft seals, pumps can lose prime during shut-down. It is extremely important to ensure that a centrifugal pump is primed before it is started [see WW, Oct. 2012]. Prior to startup, all valves between the product source and the pump suction should be open to ensure that the product reaches the pump suction. However, this does not always guarantee that the pump is primed. If the pump suction has a positive pressure, open the bleeder valve from the pump casing until all vapor is exhausted and a steady stream of product flows from the bleeder. Never operate a centrifugal pump without liquid in it.

Starting Against a Closed Valve

Low and medium specific speed pumps (below values of approx. 5,000) should be started against a closed or almost-closed discharge valve and open suction valve. A closed or almost-closed discharge valve creates a minimum load on the driver when the pump is started. Experience has shown that the discharge valve may be very difficult to open against a high pressure. Assuming that the motor inrush current allows and that the motor will not kick off, the discharge valve may be just "cracked" (about 1/8 open) before the pump is started.

This means that these pumps will operate at or near shut-off for brief periods during startup and/or shutdown. However, prolonged operation at shut-off can be harmful. At shut-off, the input energy is converted into heat, which can build up, resulting in a dangerous temperature rise of the liquid being handled and of the pump elements that are in contact with it.

When almost any centrifugal pump is started against a closed discharge valve, the pump head will be higher than normal. The shut-off head will vary with pump specific speed, as indicated above. The pump, the discharge valve and any intermediate piping must be designed for this maximum head. A closed discharge valve at startup or shutdown also prevents backflow from any static discharge head. Pumps that require less shut-off power and torque than at normal flow conditions are usually started against a closed discharge valve. If a high specific speed pump is to be started against a closed discharge valve, the high-starting torques can be avoided by the use of a bypass line.

Starting Against a Check Valve

To prevent backflow from a static discharge head prior to startup, either a discharge shut-off valve, a check valve or a broken siphon is required. When pumps are operated in parallel and are connected to a common discharge header that would permit flow from an operating pump to circulate back through an idle pump, a discharge valve or check valve must be used. The check valve will open automatically when the head from the pump exceeds the system head. As the valve opens, the pump head continues to increase, and at any flow, the head will be necessary to overcome the system static head.

Starting Against an Open Valve

High specific speed pumps (values above approximately 5,000), especially propeller pumps requiring more than normal torque at shut-off, are not normally started with a closed discharge valve because larger and more expensive drivers would be required. To avoid this situation, the discharge valve should be timed to open sufficiently to keep the motor from overloading when the pump reaches full speed. To accomplish this timing, it may be necessary to start opening the valve in advance of energizing the motor. Care should be taken to not begin opening the discharge valve too soon, as this would cause excessive reverse flow through the pump and require the motor to start under adverse reverse speed conditions.

Further, the added inertial system head produced momentarily when high specific speed pumps are started must be taken into account by considering the duration of the high transient torques and currents, the pressure rise in the system and the effect on the pump from operation at high heads and low flows.

Shutting Down Centrifugal Pumps

For low to medium specific speed pumps (below values of approximately 5,000), close the discharge valve prior to stopping the pump. This takes the load off the motor and, if any check valves leak, it may prevent reverse flow through the pump. Next, shut down the driver and leave the suction valve open.

Avoidance of water hammer is the primary concern during the shutdown of a pump, especially in installations with long discharge piping. Gradual closing of the discharge valve is one way to eliminate or reduce any water hammer pressure spikes.

Water Hammer

If the system contains an appreciable amount of liquid, the inertia of the liquid mass could offer a significant resistance to any sudden change in the velocity. Water hammer, or hydraulic inertial head, is an increase in pressure due to rapid changes in the velocity of a liquid flowing through a pipe line, and this could cause rupture or damage to the pump, piping or fittings.

This dynamic pressure change is the result of the transformation of the kinetic energy of the moving mass of liquid into pressure energy. When the velocity is changed by closing a valve or by some other means, the magnitude of the pressure produced can be much greater than the system static pressure.

The head due to water hammer in excess of normal static head is a function of the destroyed velocity, the time of closure and the velocity of the pressure wave along the pipe. The magnitude of this pressure wave also depends upon the ratio of the wall thickness to the inside pipe diameter, the modulus of the pipe material and the modulus of elasticity of the liquid. Water hammer may be controlled by regulating valve closure time, relief valves, surge chambers, and other means.

Variable Speed Drives

Finally, one of the best ways to minimize the pressure and power stresses during startup and shutdown is to install a VFD, which has many additional benefits [see WW, March 2008]. Variable frequency/speed drives eliminate the inrush current and pressure spikes on startup. Soft-starting reduces the stress on the motor, pump, coupling and the supply network.