| MBBR and IFAS use virgin polyethylene media with high-effective surface areas to grow biofilm. |

MBBR and IFAS use virgin polyethylene media with high-effective surface areas to grow biofilm. The media is retained in reactors using media retention screens, while an aeration system and/or mixers provide oxygen and mixing to allow the biofilm to provide treatment. The carrier elements thus allow for a greater volume of biomass within a given reactor. While MBBR does not use return activated sludge (RAS), the IFAS process combines both fixed-film and suspended growth (activated sludge) processes in the same reactor by using RAS to create a very small and effective treatment footprint.

A one-stage, deammonification process from Kruger for treating high-ammonia waste streams, such as centrates from anaerobic sludge digestion, brings supplemental carbon savings, up to 60 percent less energy consumption and up to 90 percent reduction in sludge production than conventional nitrogen removal.

ANITA™ Mox: An Emerging MBBR Technology

Kruger, a subsidiary of Veolia Water Solutions & Technologies, is a provider of biofilm treatment with more than 300 MGD of cumulative MBBR (AnoxKaldnes® MBBR) and IFAS (Hybas®) capacities at municipal wastewater plants throughout the U.S. With its parent company, Veolia, Kruger has recently introduced the anammox process called ANITA™ Mox.

ANITA Mox is a one-stage, energy-efficient deammonification process for treating high-ammonia, low-BOD waste streams, such as industrial effluents, landfill leachates and centrates from municipal anaerobic sludge digestion.

The process provides ammonia removal up to 90 percent in sidestream applications. The small footprint process uses the bacterium anammox to perform the task of ammonia and total nitrogen removal in a single treatment reactor. Since centrate and other ammonia-rich sidestreams are often returned to the mainstream treatment process, ANITA Mox presents a way to reduce the concentration of ammonia in many mainstream processes while requiring no additional carbon and with about 40 percent of the oxygen. It also reduces the amount of produced sludge.

Natural 'Shortcut' to Denitrification

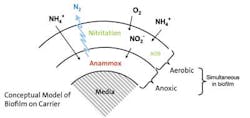

The anammox bacterium has proven to provide a natural "shortcut" in the denitrification process. ANITA Mox consists of an aerobic nitritation reaction and an anoxic ammonia oxidation (anammox) reaction. The two steps take place simultaneously in different layers of the biofilm on the AnoxKaldnes media, and nitritation occurs in the outer layer of the biofilm. Approximately 55 percent of the influent ammonia is oxidized to nitrite (NO2-), and anammox activity occurs in the inner layer. The nitrite produced and the remaining ammonia are utilized by the anammox bacteria and converted to nitrogen gas (N2) and a small amount of nitrate (NO3-). Using MBBR media allows this two-step process to occur in a single, robust, energy- efficient reactor that is simple to operate.

In the U.S., an ANITA Mox sidestream deammonification system is currently under construction at Newport News, Va., and a system is also in development in Durham, N.C. Four ANITA Mox plants are currently in operation in northern Europe - two in Sweden and two in Denmark.

BioFarm Seeding Strategy

The anammox bacterium has been known only relatively recently (theorized in the late 1970s and identified in the late 1990s). One reason is that it takes a very long time for the bacterium to grow. However, Kruger and Veolia have a strategic BioFarm/seeding strategy allowing for faster, full-scale startups of ANITA Mox. A small percentage of pre-colonized media is introduced into MBBR units during startup, accelerating the anammox growth in the system and reducing startup times. The new Durham ANITA Mox system, once fully operational, is planned to serve as Kruger's first BioFarm for seeding future U.S. installations.

The Future of MBBR