By Chip Bettle and Josh Clark

There is a global concern pertaining to wastewater treatment lagoons and their levels of sludge accumulation. Wastewater treatment lagoons are the oldest and most commonly used method for treating wastewater; however, there have been minimal advancements to improve their operation. Wastewater lagoons produce billions of tons of biosolids each year. Removal and disposal of such sludge poses a real threat to our environment and public health, as well as an immense financial burden to lagoon owners. Excessive build-up of sludge can potentially intensify odors and increase effluent concentrations of BOD, TSS, nutrients like ammonia, and pathogens.

The rising costs of managing sewage sludge together with the emergence of new compounds in sewage, including nanoparticles and pharmaceuticals, are causing headaches for many lagoon owners seeking to dispose of their sludge. Time-honored methods such as application onto farmland or landfilling are running into increased regulatory and public concern about what's contained in the sludge.

Prior to considering a potential solution, it is important to understand the root cause of the problem. Municipal treatment facilities have used similar technologies for hundreds or even thousands of years - collecting sewage flow in ponds, where natural physical and biological processes break it down into less-objectionable materials.

With the rise in environmental standards over the past 40 years, these collection and storage lagoons have been pressed into service as secondary treatment facilities through the addition of aeration. Aerated lagoons have greater treatment capacity but are more expensive to operate than a storage lagoon and tend to accumulate sludge, gradually robbing them of treatment capacity.

Mechanical treatment has emerged as an effective but expensive alternative to lagoons. In addition, they continue to generate large amounts of sludge and require highly trained staff to operate. Increasingly more lagoon owners are faced with budget restraints and are unable to adopt mechanical treatment facilities; therefore they are shifting their focus towards generating increased treatment performance from their existing lagoon systems.

The amplified costs of managing sludge can be traced back to its makeup. At more than 95 percent water, sludge is heavy, bulky and tremendously expensive to transport using conventional means. More and more lagoon owners are embracing sustainable sludge management approaches that reduce the water content onsite to control the cost of transportation.

Removing sludge from lagoons is typically accomplished by mechanical dredging, a disruptive and costly process that can cause expensive damage to infrastructure such as liners and pipes. As a result, many lagoon owners are seeking innovative, sustainable, cost effective approaches as solutions to eliminating mechanical dredging. Biodredging is a biological process that digests sludge in situ and reduces its accumulation at the onset.

Enhancing In Situ Sludge Digestion

For millennia, natural microbial systems have recycled waste and turned it into gas. Specialized bacteria liquefy biosolids; other groups convert liquids into various acids. Still another group converts short chain acids into gas. Nature optimizes the process by creating a structured environment, called a biofilm, wherein the waste from one group is handed off as food to the next group in the chain.

Absolute Aeration, LLC (Greeley, Colo.) realized that layering lagoons to mimic nature and transporting food (substrate) to immobilized biofilms faster can accelerate the gas-forming process, clean the water for discharge and digest sludge in the pond where it was formed all during the same time.

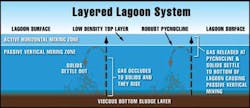

The science behind biological systems is to select for preferred indigenous organisms, layer the lagoon and then provide periodic vertical currents to transfer surface substrate to the bottom biofilm for conversion to gas (see Fig. 1).

The Blue Frog Technology uses circulators to create radial outflowing currents requiring minimal energy consumption. Each circulator unit uses a 3 HP motor to move 7 million gallons of water per day radially across the surface of the lagoon. A 30-inch floating baffle is used to redirect the horizontal flowing water downwards from the lagoon's surface to the anaerobic zone at the bottom. Selected bacteria form synergistic anaerobic biofilms in tight, mineral-based granules (see Fig. 2) on the bottom of the pond, forming a "Granular Sludge Bed Reactor" (GSBR) over the entire pond bottom.

When two adjacent radial streams intersect, equal and opposite horizontal flow vectors form a "hydraulic wall" that turns the current until it plunges to the bottom. Surface biosolids are delivered to the GSBR, liquefied, and then turned into gas by the bacteria immobilized in and on the granule.

Produced gas rises and very gently mixes the water column.

Continuously feeding the granules increases their productivity, partially offsetting the slower rate of reaction of anaerobes versus aerobes.

Once the granular sludge bed reactor is established, bacteria will grow and die back in direct response to the level of nutrient loading coming into the lagoon. This automatic biological control mechanism is ideally suited for the natural fluctuations in flow that characterize municipal sewage lagoons. Biological control is also much more cost effective than instrument control of the additional aeration horsepower associated with traditional oxygen-adding strategies.

Biological Sludge Control in Action

A small municipality (estimated population 3,200) located in the southwest United States experienced a high level of solids accumulation and ongoing challenges in meeting its discharge requirements. Its leadership team and engineer wanted to find a progressive, alternative solution to eliminate dredging, comply with discharge requirements, and reduce the costs to the city while continuing good environmental stewardship.

The initial level of solids prevented the boom from installing as engineered until two weeks later, once surface sludge was digested (see Fig. 3).

Within four months after the start of biodredging, solids levels declined approximately 31 percent and a progress report confirmed that within a five-month period the municipality was meeting all its discharge requirements (see Fig. 4).

Creating and maintaining distinct layers of water in the lagoon manages odors generated by anaerobic treatment. The top layer of clear, sweet, circulated water acts like the lid on a container keeping any odors associated with anaerobic treatment from escaping.

The modular nature of Blue Frog makes it possible to adapt to changing flows and the need for increased capacity by simply increasing the number of circulators and their inherent additional hydraulic walls. Each installation is custom designed to match the specific lagoon characteristics and meet the desired effluent discharge parameters.

Anaerobic vs. Aerobic

The benefits of anaerobic over aerobic wastewater treatment are well known to the engineering community and include significantly reduced sludge generation and lower energy consumption - the two most expensive elements of any wastewater treatment system.

Yet anaerobic treatment in sewage lagoons remains rare presumably because of the fear of odor problems and the fact that aerobic treatment provides faster overall rate of treatment.

The increasing cost of sludge management is forcing municipalities to take a hard look at their treatment infrastructure and strategies. Increasingly stringent effluent discharge criteria are placing unrealistic demands on existing treatment lagoons and forcing communities towards mechanical treatment plants they simply cannot afford. The natural solution is to enhance and improve the function of existing lagoons by adopting new approaches and strategies.

One of the key obstacles to improved lagoon performance is the conventional wisdom that supports aerobic vs. anaerobic treatment strategies. By shifting the focus from aerobic to anaerobic lagoon treatment strategies, municipalities are effectively released from the restraint of high horsepower aeration and the sludge generation that inherently comes with it. Emerging technologies such as the Blue Frog System that embrace and enhance natural biological processes give municipalities a realistic opportunity to increase the effective treatment capacity of their existing lagoons and meet effluent discharge criteria while driving down the costs of sludge management.

About the Authors: Chip Bettle is Co-Inventor & Executive Vice President of Engineering for Absolute Aeration, LLC, (Greeley, Colo.) Josh Clark, M.Sc., is Aquatic Ecologist, Senior Project Manager at C&M Aquatic Management Group Ltd. (Owen Sound, ON, Canada). For all inquiries, please contact Brandi Waters at [email protected]