LONDON, England – The global race continues to scale up and commercialise the use of the super material graphene for water applications.

Scientists in the UK have now found a way to stop graphene oxide membranes swelling up during water filtration.

Previous efforts found that graphene oxide membranes could filter out nanoparticles, organic molecules and even large salts but struggled with common salts. When immersed in water, however, the membranes would expand, allowing smaller salts to flow through the pores.

Dr Raul Nair from the University of Manchester has demonstrated that by placing walls made of epoxy resin either side of the graphene membrane, it stopped the expansion.

By restricting the swelling, this also allowed the scientists to ‘tune’ the properties of the membranes, letting less or more common salt through, the BBC reported.

He said: “In terms of scalability and the cost of the material, graphene oxide has a potential advantage over single-layered graphene.”

The results from the work were published in the journal Nature Nanotechnology.

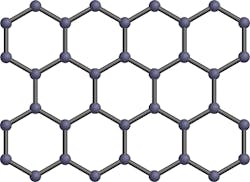

First isolated by the university in 2004, graphene – at one atom thick - has since been heralded as a new super material: stronger than steel and diamond, yet flexible with heat and electrical conductivity properties.

It consists of carbon atoms arranged in a perfect hexagonal lattice and is being considered for multiple developments and industries, from solar panels through to mountain bikes.

The video from the University of Manchester explains in greater detail:

For desalination, US Professor Jeffrey Grossman from MIT’s Department of Materials Science and Engineering discovered that pores sized 0.8 nanometers need to be created in the material. This allows water to pass through but not salt.

The challenge is making multiple small holes, in a controlled and uniform way across graphene without compromising strength.

Meanwhile Abu Dhabi research arm the Masdar Institute has been experimenting with graphene to filter water without creating holes. As can be seen from 5.40 in the video interview below, Dr Steve Griffiths said the institute has been layering graphene, to allow water filtration without the need to perforate the material.

While it has been expensive and challenging to produce single layer graphene using exiting methods, such as chemical vapour deposition, the University of Manchester’s Dr Nair said that graphene oxide “can be produced by simple oxidation in the lab”.

Many sources have pointed to the graphene development as being the answer to cheaper and more energy efficient desalination globally, yet the material is still at an extremely early stage.

The real test will be scaling up the graphene oxide, comparing it to new, polymeric membranes when treating seawater and addressing how resistant it is to biofouling.

Dr Nair added: “This is our first demonstration that we can control the spacing [of pores in the membrane] and that we can do desalination, which was not possible before. The next step is to compare this with state-of-the-art material available on the market.”

Dr Graeme Pearce, principal at Membrane Consultancy Associates (MCA) told WWi magazine: "The development at the University of Manchester aims to produce a membrane with a highly controlled character, free from defects. Given the materials used, longevity should also be good. The challenge will be whether the membrane can be effectively used with the current form factor (the spiral wound element mounted in series in long pressure vessels) and using current process design concepts.

"Alternatively, the membrane might be better exploited by a completely different approach to process design, which would be high risk and slow to introduce, but might have a much greater long term impact if the improved membrane can be exploited more efficiently."

He added: "The key issue would be to demonstrate both performance and longevity in the first instance and then establish what features of the current approach to desalination plants limit the benefits of a new membrane and what can be done to remove these impediments."

Elsewhere in the UK, G2O is commercialising a development by the University of South Carolina in which a graphene oxide coating is applied to an existing polymeric membrane.

Pearce added: "This preserves the form factor and should be more easily adopted by the industry. The development is still early stage and the longevity of the coating has yet to be established, but the approach appears to be promising and initial results on performance enhancement have been encouraging. This is more likely to allow a radical optimization of existing practice rather than the potentially more revolutionary but higher risk development from Manchester."

###

Read/watch more

Australian partnership hopes to disrupt filtration market with graphene-based tech