A European Union funded project set out to demonstrate the environmental and socio-economic benefits of a synergic co-treatment of sewage sludge and wastes. This article addresses the findings and how the technology could fit in with existing sludge treatment processes.

By Andrés Pascual

The treatment of sludge has become an essential part of current wastewater treatment plants (WWTPs). In fact, the operation costs of sludge treatment are responsible for approximately 50 percent of those of a sewage treatment plant.

In 1986 the European Union published the Directive 86/278/CEE, which establishes limits on the protection of the environment, and in particular of the soil, when sewage sludge is used in agriculture, and thus why the disposal of sludge has become a priority for local authorities. Moreover, the EU is actually working in a new document that will establish more constraining limits in parameters such as heavy metal, micro-pollutants and pathogens.

The Directive 96/61/CE concerning integrated pollution prevention and control states that the treatment of sewage sludge should be based on the best available techniques, taking into account the characteristics of the installation concerned, its geographical location and environmental conditions.

Consequently, ongoing interest has been drawn to the development of methods for sludge remediation and resource recovering. In 2011 sludge treatment in Spain was mainly carried out by anaerobic digestion (30 percent), composting (30 percent), thermal drying (20 percent) and other treatments such as lime stabilization or incineration. Despite these methods usually reduce organic matter content and volume of sludge, most of them are unable to completely eliminate hazardous pollutants, which could even considerably reduce the efficiency of the treatment (e.g., anaerobic digestion).

Great potential

In recent years the Supercritical Water Oxidation (SCWO) technology has shown great potential to offer complete destruction of the organic fraction of the sludge, converting it into simple molecules such as carbon dioxide and water. Furthermore, the residual inorganic fraction from the process can be subject to further processing to recover phosphorous with potential applications in agriculture. The energetically self-sustainable character of the process, able to generate energy when properly operated, is of particular interest.

Lo2x is a LIFE Environment funded project that aims to demonstrate the technical, economic and environmental viability of SCWO technology to treat low quality urban sewage sludge, not eligible for agricultural use, together with other organic wastes generated near the WWTPs such as drencher wastewater, landfill leachates, olive mill wastewater or pig manure.

The project is co-financed by the European Union through LIFE programme, with a total budget of €2.9 million (EU contribution represents 50 percent). The consortium includes representatives of several sectors and it is performed through a cross-border collaborative model between Spain and Ireland.

AINIA technological centre led the Lo2x project in cooperation with four more partners: IMECAL, as specialist in equipment construction; IVEM, as responsible for the Paterna-Fuente del Jarro WWTP and specialist in process automation; SCFI, as hi-tech company with a consolidated expertise in advanced hydrothermal oxidation processes; and URBASER, as specialist in the provision of environmental services.

Reaching critical point

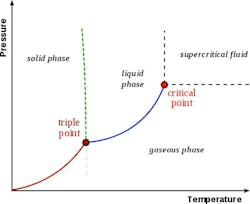

Supercritical Water is a unique medium that has been studied for a growing and increasingly diverse number of applications. Above its thermodynamic critical point (374°C, 221 bar), water exists as a single phase with transport properties comparable to those of a gas and solvent properties.

Unlike other supercritical fluids, water undergoes a significant change in its solvent behavior between ambient and supercritical conditions. As water is heated under pressure, it loses a sufficient amount of its hydrogen bonding to transition from a highly polar solvent to nonpolar solvent.

This phenomenon is evidenced by the dramatic drop in water’s dielectric constant near the critical point and beyond; additionally, once the critical point is surpassed, the dissociation constant decreases its value dramatically. The result is that supercritical water becomes a very good solvent for nonpolar materials.

The oxidation process occurring in water under supercritical conditions, the so called SCWO process, leads to rapid destruction of a wide variety of organic species, normally considered to be refractory or difficult to break down under conventional treatments, to more simple molecules (such as CO2 and H2O) in quite short reaction times.

For this reason, this technology has already been used for the treatment of a wide variety of wastes, including sludge. In fact, SCWO can achieve an organic matter removal >99 percent operating at reaction times of less than a minute. Main products include water, CO2 and inorganic salts. Although the SCWO’s gas emissions mainly and inherently contain CO2, no highly harmful emissions (NOx, SOx) do occur, unlike what happens with other thermal treatments such as incineration.

Constructing a prototype

In order to perform a demonstration, one of the key objectives for LIFE Lo2x was to design and construct a prototype for the supercritical water co-oxidation of urban sludge and other wastes. The developed prototype, localised in Paterna-Fuente del Jarro WWTP (Valencia, Spain), is able to treat up to 1 tonne of dry matter per day.

The following results were achieved during the experimental campaign of the LIFE Lo2x project:

- > 99% elimination of organic matter. The COD of SCWcO effluent is in average lower than 200 mgO2/L, reaching values even lower than 25 mgO2/L

- 100 percent elimination of pesticides. Imazalil is degraded through SCWcO up to 350 mg/kg, four orders of magnitude higher than the concentration removed by anaerobic digestion

- 100 percent elimination of pathogens. Escherichia coli, Clostridum perfringens and Salmonella are completely eliminated. SCWcO leads to complete sterilization

- >85 percent heavy metals are recaptured for safe handling. Heavy metals are mainly detected in inorganic solid fraction of the SCWcO effluent.

- Recovery of nutrients. Mineralization of nitrogen and phosphorus facilitates the nutrient recovery in order to be used as building blocks of fertilizers. Nitrogen occurs in the liquid phase (NH4~2 g/L) while phosphorus is present in the inorganic solid fraction of the SCWcO effluent (P2O5~25 percent)

- No highly harmful gases are produced. CO2 is the main gas generated by SCWcO. Typical undesired gaseous products from the combustion processes as NOx and SOx are not produced.

- 98 percent reduction of sewage sludge leaving WWTP. Total solid reduction higher than 90 percent. The inorganic solid fraction from SCWcO is a resource for phosphorous industry whereas wastes from anaerobic digestion may end up in the landfills

- Zero heat consumption. The heat produced by the oxidation under supercritical conditions (highly exothermic reaction) makes pumping to be the only significant energy-consuming step (i.e., 1 kWh/kg dm) through SCWcO

- >10% reduction in sludge treatment cost. The gate fee thanks to co-substrate treatment by SCWcO allows reducing the cost of sludge treatment below the cost of anaerobic digestion.

Advantages and disadvantages of existing sludge treatments

It must be remarked the importance of performing an initial study including the objectives, possibilities, and limitations of each technology in order to comply with the statements of Directive 96/61/CE, looking for introducing the best available techniques in the concerned installation. For instance, it must be taken into account that some technologies such as lime stabilization, thermal drying or aerobic digestion are limited by their low applicability in plants of large dimensions.

Likewise, there are technologies sensitive to ambient changes (pH, temperature, climate conditions and moisture changes), restricting the type of sludge that can be treated and even the region where the plant will be installed, depending on climatic conditions. Furthermore, some treatments can promote bad odor generation, entailing an important problem if the installation is very close to urban settlements. Another important limitation that must be accounted prior to select a sewage sludge treatment is the space available to install this plant, since some treatments like composting require large land extensions and long treatment times.

Usually, sludge treatments can reduce the volume of generated waste. Nonetheless, in some cases such as lime stabilization this quantity may be not reduced but increased after chemical products addition.

Besides these general considerations, special attention should be paid on the presence of contaminants of emerging concern with high toxicity for humans and ecosystems. For this reason, both companies and researchers have stated that will apply further efforts on the development and improvement of powerful technologies capable to eliminate these contaminants and mitigate associated negative effects.

To date, few techniques proved potential enough to afford this goal but recently, SCWcO emerged as a promising technology which may afford the integral and complete remediation of sewage sludge. Lo2x project´s results have definitely contributed to demonstrate that it is possible to take advantages of the synergic treatment of sludge with other residues by SCWcO.

Conclusions

Technologies that produce an effective and economical reduction of the level of pollutants, combined with the recovery of energy and nutrients present in the sludge as fertilizers (i.e., phosphorus and nitrogen) will have a considerable demand in the future.

This is leading to a search for new and appropriate sludge treatment and/or recovery processes, including Supercritical Water co-Oxidation technology. SCWcO technology has been discussed as a potential method for handling sewage sludge due to the complete degradation of organics and the reduced risk of pollutants with emerging concern.

In fact, as demonstrated in the LIFE Lo2x project, the Supercritical Water Co-Oxidation technology is appropriate to treat sewage sludge together with other organic wastes (e.g., pesticide wastewaters, landfill leachates, olive mill wastewater or pig manure), since it has been proven to achieve: almost complete degradation of organic matter, reduction of inert solids, sterilization, capture of heavy metals for safe handling and recovery of nutrients. All of this was reached with a zero heat consumption, disposing gases free of highly harmful compounds and an overall reduction in sludge treatment cost.

Therefore, results from the LIFE Lo2x project have paved the way for bringing this innovative technology to the Spanish market.

Andrés Pascual is an agricultural engineer from Universidad Politécnica de Valencia. He has almost 20 years of experience at the AINIA Technology Center.

More Water & WasteWater International Archives Issue Articles