Zero Discharge Desalination Holds Promise of Maximum Water Recovery

By Emily Gilbert

Increasing population, decreasing water supply, and droughts are leading to increased competition between users of freshwater. Zero Discharge Desalination (ZDD) is being studied to maximize the volume of water produced from brackish sources while minimizing impacts to the environment caused by concentrate disposal.

ZDD has been evaluated at several locations including New Mexico, Texas, California and Florida. Pilot studies have demonstrated overall water efficiencies of 95-99% on brackish groundwater with sparingly soluble calcium sulfate and moderate silica levels. This article presents treatment results from recent ZDD testing at the Brackish Groundwater National Desalination Research Facility (BGNDRF) in Alamogordo, NM, and evaluates the economics of a ZDD solution for the city of Alamogordo.

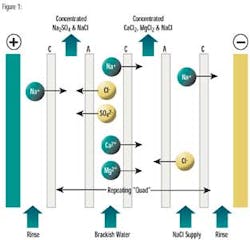

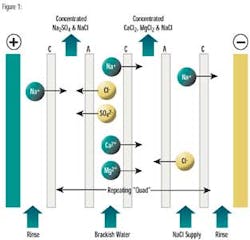

In the Zero Discharge Desalination process, the concentrated salts rejected by a conventional RO or NF system are fed to an electrodialysis metathesis (EDM) stack comprised of ion exchange membranes and thin solution compartments. The EDM acts as a "kidney," removing salts by "metathesizing," or "switching-partners," between the ions in the RO/NF waste brine and a feed sodium chloride stream. The process is described in Figures 1 and 2.

A direct electric potential is applied to the ends of the stack, resulting in a direct current that is carried by ions migrating through the membranes and solution compartments. The DC potential pushes ions through membranes from a lower-concentration to a more concentrated solution.

The primary difference between Electrodialysis (ED) and EDM is an innovative arrangement of ion exchange membranes, designed to separate concentrate into two streams of highly soluble salts. A four-compartment electrodialysis metathesis stack is used, in which there are two depleting streams and two concentrating streams. The two depleting streams are RO or NF concentrate, typically rich in calcium salts, and sodium chloride (NaCl) feed. The two concentrating streams are mixed sodium salts, and mixed chloride salts.

In some cases, the two highly-concentrated streams can be combined to precipitate a byproduct such as gypsum (calcium sulfate).

ZDD Testing at Alamogordo

The University of Texas at El Paso's Center for Inland Desalination (CIDS) was awarded funding from the US Bureau of Reclamation's DWPR program to pilot test ZDD. This effort is a collaborative project between CIDS and Veolia Water Solutions & Technologies. During the first year, the project was located at the BGNDRF. Prior to this study, the ZDD configuration consisted of RO and EDM. Through testing at BGNDRF, the team successfully demonstrated a ZDD configuration utilizing NF in lieu of RO membranes (see Figure 1).

By using NF instead of RO, the team eliminated the need for costly silica removal systems (the silica levels from the ground water supply were high enough in the RO concentrate stream that it scaled the EDM membranes). Uncharged species, such as silica, are not removed by electrodialysis, but NF membranes allow passage of silica into the permeate.

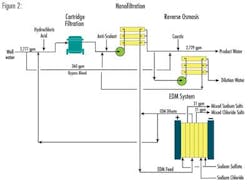

The feed water had about 3,000 mg/L TDS and the treated water was below 800 mg/L TDS, matching the water quality currently distributed to Alamogordo users. The recovery by NF and EDM was 98% compared to 75% recovery by conventional RO. Further details of the water quality are shown in Table 1.

Economic Comparison

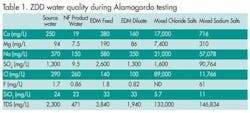

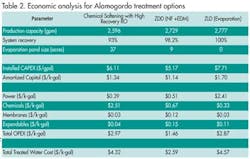

The Alamogordo project demonstrated that ZDD can achieve higher water recoveries than conventional softening followed by high-recovery RO and at lower life-cycle costs than conventional softening followed by high-recovery RO or than ZLD evaporation.

An economic analysis was performed for the three treatment options. Assumptions for the economic analysis included:

- Feed flowrate 4 mgd (2,777 gpm)

- Installed CAPEX includes treatment equipment and evaporation ponds

- Amortization period of 20 years at 5% interest

- Evaporation rate of 20 cm/month

- Based on BGNDRF data, evaporation pond cost in Alamogordo is $130,000 per acre

- Land acquisition costs estimated at $15,000 per acre

- Operating costs includes cost of power, chemicals, membranes (RO, NF and EDM) and expendables (cartridge filters, and EDM anodes and cathodes).

The analysis is presented in Table 2 in terms of $/k-gal water produced. Results show that in situations where recovery >90% is required, a ZDD solution is more economical than other high recovery approaches in terms of both CAPEX and OPEX.

Salt Recovery Experiments

Several experiments are underway in the laboratory evaluating the potential to recover useful salts from the two ZDD waste streams. Sodium chloride (NaCl), calcium sulfate (CaSO4), sodium sulfate (Na2SO4), magnesium chloride (MgCl2) and magnesium hydroxide (MgOH2) are potentially recoverable to a varying degree. CaSO4 is used in wall board manufacturing and in dental implants, while Na2SO4 is used in detergent manufacturing. The economic viability of recovering such products depends on the market for the salts and whether enough salt is produced to warrant selling. For example, if there is a detergent manufacturing facility within relatively close proximity to the water treatment plant, then recovering Na2SO4 could be worthwhile.

The main goal of the salt recovery experiment is to recover a sodium chloride which could be used as feed to the EDM. The cost of NaCl for addition to the EDM is a substantial part of the ZDD operating cost.

Experiments have been performed in the laboratory using synthetic water, and in the field using EDM concentrate streams at a ZDD pilot site in La Junta, CO. Results from these experiments are still being evaluated and will be published at a later date.

Future Testing

Future testing by the team will operate a larger ZDD system incorporating two full-scale EDM stacks. Testing will confirm energy consumption and salt usage of the EDM system, as well as overall water recoveries achievable by the technology. Further testing will also evaluate the viability of creating salable byproducts from the EDM waste streams.

Testing will also evaluate the potential for incorporation of renewable energy. Options include a paper study on the incorporation of solar power for the EDM systems and laboratory and/or field scale demonstration of solar drying methods for solids recovery in the ZDD process.

Conclusions

The Zero Discharge Desalination (ZDD) process, using NF and EDM, maximizes the volume of product water from the brackish source while minimizing impacts to the environment caused by concentrate disposal. The economic analysis presented concludes that in situations where recovery >90% is required, a ZDD solution is more economical than other high recovery approaches in terms of both CAPEX and OPEX. Further testing will evaluate the exciting possibility of recovering salable byproducts or NaCl from the ZDD waste streams.

About the Author: Emily Gilbert is the Membrane Product Manager for Kruger, based in Las Vegas, NV. She has been with Veolia since 2002, working in both their Kruger US and Birmingham UK offices on the Hydrotech Discfilter product and the Kruger Membrane products. She is a graduate of Chemical Engineering from Texas A&M University. Co-authors who assisted in this project include Brad Biagini, Veolia Water Solutions & Technologies, Pittsburgh PA; Bernie Mack, Veolia Water Solutions & Technologies, Boston MA; Malynda Capelle, UTEP Center for Inland Desalination, El Paso TX; and Dr. Tom Davis, UTEP Center for Inland Desalination, El Paso TX.