Innovations making a splash in the water industry

Human beings, while able to survive without food for about 21 days, can only live without water for three. And while clean water is a must for everyone, it can sometimes be challenging to get to. It’s no wonder that researchers, students, and start-up companies are focusing on finding new ways to disinfect drinking water, filter out contaminants, and detect water-quality issues.

Leading the Way on Lead

One company aims to help utilities track and manage contamination at its source: in the homes and offices of consumers. 120WaterAudit was recently recognized by Imagine H2O as a thought leader in the water industry and its point-of-use Water AuditSM testing kits, software, and corresponding cloud-based platform for managing lead service line replacement have helped its clients test over 100,000 locations across nine U.S. states.

The list of 120WaterAudit’s clients include Indiana Finance Authority (whom the company helped to implement a statewide school lead-testing program), the state of Maryland, and Chicago schools and daycares. The company is also working with cities and municipalities in Pittsburgh, Kenosha, Wis., and Hamtramck, Mich.

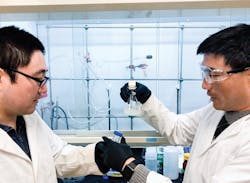

(L-R) Fei Zhao and Guihua Yu of Yu Research Labs at UT Austin examine a sample of their newly-developed hydrogel. Photo Courtesy Cockrell School of Engineering, The University of Texas at Austin.

The company says its programs allow states and utility districts to “manage and execute water quality programs that scale, save operational resources, and help managers improve public health outcomes.” It’s a noble mission, and one whose time has come as regulations continue to change.

Moisture-Harvesting Powered by the Sun

Engineers at The University of Texas at Austin’s Cockrell School of Engineering have developed a water treatment technology that uses solar-powered technology that absorbs moisture from the air and returns it as clean, usable water. The research team, led by Guihua Yu, says this could be used in disaster situations, water crises or poverty-stricken areas and developing countries. The technology relies on hydrogels, gel-polymer hybrid materials designed to be “super sponges” that can retain large amounts of water.

“We have developed a completely passive system where all you need to do is leave the hydrogel outside and it will collect water,” said Fei Zhao, a postdoctoral researcher on Yu’s team and co-author of the study. “The collected water will remain stored in the hydrogel until you expose it to sunlight. After about five minutes under natural sunlight, the water releases.”

When left out in the sun, the membrane’s reduced graphene oxide flakes generated heat into the surrounding water and bacteria nanocellulose. Photo Courtesy Young-Shin Jun and Srikanth Singamaneni.

This technology builds upon a 2018 breakthrough made by the researchers, in which they developed a solar-powered water purification innovation using hydrogels that cleans water from any source using only solar energy. The team’s new innovation takes that work a step further by using the water that already exists in the atmosphere.

For both hydrogel-based technologies, Yu and his research team developed a way to combine materials that possess both water-absorbing qualities and the ability to release water through applying heat. The new technology is also significantly less energy-intensive than previous atmospheric water generation techniques.

Prototype testing showed daily water production of up to 50 liters per kilogram of hydrogel. Yu and his team have filed a patent, and he is working with UT’s Office of Technology Commercialization on the licensing and commercialization of this innovative class of hydrogels.

Ultrafiltration Membranes Bettered by Bacteria

Washington University in St. Louis engineers looked to the very bacteria they were trying to stamp out of water systems to design a membrane-based technology that purifies water.

A team led by Srikanth Singamaneni, professor of mechanical engineering and materials science, and Young-Shin Jun, professor of energy, environmental and chemical engineering, used graphene oxide and bacterial nanocellulose to develop an ultrafiltration membrane. The engineers took Gluconacetobacter hansenii bacteria and applied a sugary substance in water, which resulted in the formation of cellulose nanofibers. By adding graphene oxide (GO) flakes into the bacterial nanocellulose while it was growing, the membrane became stable and durable. Then, the membrane was treated with base solution to kill the Gluconacetobacter. During this process, the oxygen groups of GO are eliminated, making it reduced GO. When left out in the sun, the membrane’s reduced GO flakes generated heat into the surrounding water and bacteria nanocellulose.

“If you want to purify water with microorganisms in it, the reduced graphene oxide in the membrane can absorb the sunlight, heat the membrane and kill the bacteria,” Singamaneni said.

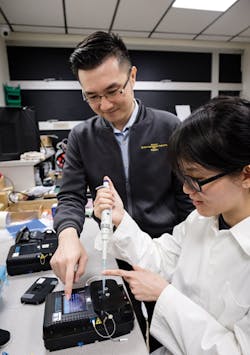

L-R: Assoc Prof Yong Ken-Tye and his PhD student Stephanie Yap, both from the NTU School of Electrical and Electronic Engineering, developed a portable device, inspired by the ability of the human body to detect trace levels of heavy metals in drinking water in just five minutes. Photo Courtesy NTU Singapore.

To test their new treatment technology, the team exposed the membrane to E. coli bacteria, then shone light on the membrane’s surface. After three minutes, the E. coli bacteria died, and the researchers had “a pristine membrane with a high quality of nanocellulose fibers that was able to filter water twice as fast as commercially available ultrafiltration membranes under a high operating pressure,” according to the university.

“This is like 3-D printing with microorganisms,” Jun said. “We can add whatever we like to the bacteria nanocellulose during its growth. We looked at it under different pH conditions similar to what we encounter in the environment, and these membranes are much more stable compared to membranes prepared by vacuum filtration or spin-coating of graphene oxide.”

While the researchers acknowledge that implementing this process in conventional reverse osmosis systems is taxing, they propose a spiral-wound module system, similar to a roll of paper towels. It could be equipped with LEDs or a type of nanogenerator that harnesses mechanical energy from the fluid flow to produce light and heat, which would reduce the overall cost.

If their technique were to be scaled up to a large size, it could benefit many developing countries where clean water is scarce.

The NTU device works in the field and requires just a few drops of a water sample into a disposable sensor cartridge to detect heavy metals at parts-per-billion precision. Photo Courtesy NTU Singapore.

Metal Detection that Mimics Nature

The human body has a natural defense mechanism against metal poisoning the bloodstream. Using these same systems as inspiration, scientists from Nanyang Technological University in Singapore (NTU Singapore) developed a device that detects trace levels of up to 24 types of heavy metals — including lead levels of 5 parts per billion — in drinking water in five minutes.

“The secret lies in an organic substance within the bloodstream, called a chelating agent,” an official release from NTU said.

“This can detect and bind to heavy metal ions. After binding, it prevents the heavy metal ions from interacting with other molecules and enzymes in the body, and marks it for excretion from the body.”

Associate Professor Yong Ken-Tye and Professor Tjin Swee Chuan combined a chelating agent with an optical measurement system in a portable unit, ideal for on-site water testing.

The researchers explained how the sensor works: “A laser is shown through an optical fiber sensor modified with the chelating agent. In a water sample contaminated by heavy metals, the metal ions will bind to the chelating agent on the optical fiber sensor. This induces a shift in the output light spectrum, from which the device’s processing unit then calculates the concentration of heavy metals in the sample.” The process uses only a few drops of water and takes about five minutes to get results.

The creators of the device say it could easily be integrated into any existing water treatment plant.

In this photograph of the experimental setup in an ETH Zurich laboratory, a researcher uses a pipette to put a sample onto a molography chip. Photo Courtesy ETH Zurich / Andreas Frutiger.

Monitoring by Microchip

Scientists at ETH Zurich, working with the company Roche, have developed a method of analysis based on the principle of light diffraction on molecules on a small chip. While the process was designed with physicians in mind, further applications could include quality control for drinking water treatment or process monitoring in the biotechnological industry.

Using a molography chip with a specially coated surface made up of tiny dots with a specific striped pattern, the molecules in question (or contaminants) bind to the stripes but not to the spaces between them. When a light is shone on the chip’s surface, it is bent based on the way the molecules are arranged on the chip and a point of light becomes visible. This reaction did not occur in samples without the contaminants.

According to the research team, the method “is so fast that it is even suitable for real-time measurements, which is of particular interest for basic biological research.”

References

1. Guo, Youhong, Fei Zhao, Xingyi Zhou, Zhichao Chen and Guihua Yu, “Tailoring Nanoscale Surface Topography of Hydrogel for Efficient Solar Vapor Generation,” Nano Letters. 10.1021/acs.nanolett.9b00252, 2019.

2. Jiang, Q., et al. “Photothermally Active Reduced Graphene Oxide/Bacterial Nanocellulose Composites as Biofouling-Resistant Ultrafiltration Membranes,” Environmental Science & Technology. DOI: 10.1021/acs.est.8b02772, published online Sept. 14, 2018; print Jan. 2, 2019.