Desalinating a Moving Target

Brackish water presents a unique challenge when it comes to water treatment. Created when freshwater and seawater meet, causing a mixture of the two, brackish water can usually be found around river deltas or wetlands.

As water quality is expected to degrade over time, the problem becomes anticipating the salinity of the water and applying proper treatment to produce clean water. Officials in North Port, Fla., faced this precise obstacle and they ended up overcoming it with a solution never before used in the United States.

An Evolving Challenge

The North Port Water Treatment Plant treats groundwater from the Floridan Aquifer, which in areas has salinity similar to seawater conditions of the Gulf of Mexico. The water comes primarily from groundwater wells and the nearby Myakkahatchee Creek. According to a 2021 report, the average adult household of two uses nearly 4,000 gallons of water per month in North Port — well below the national average of more than 5,000 gallons.

As engineers prepared to design a new brackish water reverse osmosis (BWRO) facility capable of producing 2 million gallons per day (MGD), set to startup in Q2 of 2022, they needed to think ahead to accommodate the projected changes in both raw water quality and capacity.

The facility will bring in water from raw water wells with total dissolved solids (TDS) of about 3,500 mg/L at startup. However, because nearby wells have shown signs of quick degradation, the City anticipates that the raw water quality will also degrade over time. Looking at the historical trends, salinity could increase by as much as 370 percent in the first 10 years of operation, reaching levels of up to 13,000 mg/L. To anticipate this, the facility was also designed with two reverse osmosis (RO) skids, each capable of producing 1 MGD, with the possibility to expand to produce 2.5 MGD each as demand for water rises.

Increasing salinity presented not only a design challenge but also a significant potential jump in energy load and other costs for the facility. Some of the major expected impacts on the facility included increased membrane feed pressures, larger horsepower requirements for membrane feed pumps, increased energy load, and more complex materials selection matrices for wetted metal components. Combined, these issues can also lead to higher capital and operational costs.

Addressing the Issue

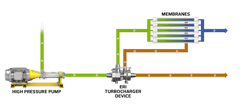

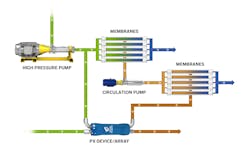

Traditionally, BWRO facilities employ turbochargers as an interstage booster pump. However, because of the expected increase in feed pressure (between 200 to 520 psi) and other operating conditions, this would not work. Because traditional turbochargers are designed to operate in a narrow range of operating conditions, they would not be able to provide the necessary pressure boost needed under future conditions.

The PX was better suited for this facility as it offered operational flexibility, easily accommodating several operational points without the need for extra equipment. Turbocharger efficiency is heavily dependent on a project’s specific flow and pressure, and any variations can cause significant drops in efficiency. By contrast, the PX is not negatively impacted by changes in pressure, and efficiency actually increases as pressure increases.

Forward-Thinking Results

By anticipating the changes in operating conditions, installing the PX, and streamlining the design, the facility owner was able to achieve savings in capital and operating expenses. These savings include a 20 percent reduction in the high-pressure membrane feed pump flow, which could lead to an estimated reduction in horsepower (HP) of at least 33 HP, and $95,000 in reduced capital savings for the pump motor and other components.

Additionally, the facility will continue to realize savings in the operating expenses over the PX’s 25-year lifecycle. Based on current production and salinity levels, it is estimated that the facility will see an energy savings of 1.7 kWh/kGal, which translates into an annual savings of $23,360. As salinity and production increases, those savings could compound significantly over time to as much as $211,000 per year, under the maximum projected TDS and production capacity.*

What was originally thought to be a stumbling block has now become a strength for North Port. In the same way that brackish water is a confluence of freshwater and seawater, this solution resulted from a combination of addressing a current issue while also looking ahead to anticipate future needs. Ultimately, it shows that even evolving challenges have solutions, allowing plants to prepare for the future while continuing to save money and energy. WW

About the Authors: David Kim-Hak is senior product director at Energy Recovery Inc. Kim-Hak has almost 20 years of experience in water and wastewater treatment processes and technologies, with an expertise in RO desalination. He holds a BS and MS in Chemical Engineering from UC Berkeley and USC.

Juan Miguel Pinto is director of sales and strategy for the Americas at Energy Recovery Inc. Pinto has been involved in the water industry for more than 14 years. He graduated from the University of Florida in 2019 with a master’s degree in Business and Administration. He serves on the Board of Directors of the International Desalination Association (IDA), and he is President of La Asociación Latinoamericana de Desalación y Reusó (ALADYR).

Published in WaterWorld magazine, June 2022.

*updated 6/24/22

About the Author

Juan Miguel Pinto

Juan Miguel Pinto is director of sales and strategy for the Americas at Energy Recovery Inc. Pinto has been involved in the water industry for more than 14 years. He graduated from the University of Florida in 2019 with a master’s degree in Business and Administration. He has authored and co-authored over 20 international publications. Juan serves on the Board of Directors of the International Desalination Association (IDA), and he is President of La Asociación Latinoamericana de Desalación y Reusó (ALADYR).

David Kim-Hak

David Kim-Hak is senior product director at Energy Recovery Inc. Kim-Hak has almost 20 years of experience in water and wastewater treatment processes and technologies, with an expertise in RO desalination. He holds a BS and MS in Chemical Engineering from UC Berkeley and USC.