Advanced oxidation process (AOP) technology is emerging as a new best practice in water treatment. It is particularly attractive to utilities experiencing threats to their source water quality due to nuisance algae issues, which can create displeasing taste and odor compounds.

One South Carolina water utility implemented a state-of-the-art ozone AOP system to achieve its drinking water treatment objectives within budget and timeline parameters.

Taste and Odor Challenges

The Anderson Regional Joint Water System (ARJWS), a wholesale drinking water provider to 14 water utilities in upstate South Carolina, was facing a sizable public relations issue due to ongoing taste and odor issues in its finished potable water.

ARJWS officials tried a variety of solutions, such as copper- and peroxide-based algaecides for in-lake treatment. Adding powder activated carbon (PAC) and chlorine dioxide in the treatment plant to adsorb and oxidize the compounds did not deliver the desired results either, due to the high concentrations of compounds being generated by the algae. Then Lake Hartwell experienced an even larger bloom in 2014, continuing the troubles for ARJWS.

After these methods were unsuccessful, ARJWS directed its engineering consultant Goodwyn, Mills and Cawood (GMC) to explore a treatment system upgrade to eliminate seasonal taste and odor events, remove the color associated with naturally occurring iron and manganese, and establish resilience against algae-linked compounds and other contaminants of emerging concern.

Finding a Solution

Through its representative Premier Water, Xylem Inc. teamed up with GMC in 2016 to begin the multiphase process of determining the most viable treatment option in terms of objectives, lifecycle costs, and total cost of ownership.

Based on the nature of the contaminants, Xylem designed and executed a treatability study featuring ozone and two other advanced oxidation processes: ozone/hydrogen peroxide, as well as ozone/ultraviolet (UV) light.

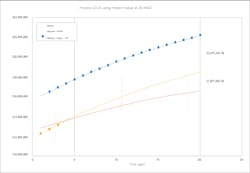

Results of the study indicated that ozone alone would be sufficient for most operating conditions and provide the lowest lifecycle cost based on a 20-year evaluation. However, detailed analysis of augmenting ozone with hydrogen peroxide showed that, while the lifecycle cost would increase slightly, the ARJWS capital expenditure would be reduced with the use of a smaller ozone contactor basin. Additionally, ozone AOP was determined to be the most viable overall option because it provided operational flexibility and an additional AOP barrier when needed.

The full-scale state-of-the-art system consisted of two Wedeco PDOevo 900 Ozone AOP Systems for the newly constructed treatment facility.

The Results

In the first six months of operation, MIB and geosmin concentrations in Lake Hartwell were down significantly from previous years, though still at levels detectable by ratepayers. At the start of the algae bloom season, the ozone AOP system eliminated 99.9 percent of the incoming MIB/geosmin, resulting in non-detect values in the outlet. Color has consistently been clear with the increased removal of iron and manganese.

The effectiveness of the preoxidation process is bringing considerable operational efficiencies to the utility’s clarification and filtration systems. Additionally, trihalomethanes (THME) levels were reduced by more than 50 percent due to the ozone treatment and reduced chlorine use.

With PAC no longer in use, the plant is saving more than $500,000 per year in consumables, plus many operating and servicing hours.

“We consistently went over our $125,000 annual solids removal budget for our onsite lagoons when PAC was used, which [was] also diminishing the available capacity in the lagoons,” says Jennifer Barrington, ARJWS System Engineer. “Those same funds now enable the plant to remove nearly double the solids annually produced.”

Upfront chlorination to keep the media filter cleaner is no longer required, reducing overall chlorine use by 50 percent. This results in a savings of about $40,000 to $50,000 annually and is expected to significantly increase the overall life of the chlorine system.

The most important result, according to Scott Willett, ARJWS executive director, is the utility has not received a single complaint from any of its 200,000 customers about the water since the new treatment plant came online. WW

About the Author: Ralph Franco, P.E., is director of engineering for Xylem’s North American Treatment Business. Based in Zelienople, Pa., Franco has been in the water and wastewater industry for over 30 years.