Stormwater/CSO System takes ‘Treatment Train’ Approach

Changing national, local and state requirements have added a sense of urgency to find new solutions to new regulations for stormwater and CSO discharges. To that end, a company that has made trash net systems since 1992 has expanded its product line to include a “treatment train” concept that goes beyond simple trash removal and will include a non-chlorine disinfection system.

The SiteSaverTM Managed Discharge Systems from Fresh Creek Technologies incorporates a series of unit operations: sediment/grit removal, oil/grease removal, disinfection, and other treatments for constituents of concern. The company also is researching a relatively new disinfection chemical that breaks down within minutes and leaves no toxic residuals.

Fresh Creek offers a variety of net capture systems and its Netting TrashTrap® system has been listed by the EPA as a Best Management Practice (BMP) for both Stormwater and CSO. However, netting system solutions for trash and floatables are only one part of the treatment train concept.

The SiteSaver system consists of customizable modules that allow a customer to choose one or more treatment options to meet their specific Stormwater/CSO treatment requirements.

In its low flow configuration, the SiteSaver system uses two of its modular units linked together. Stage 1 is the TRASHMASTERTM unit designed to remove gross waterborne pollutants (trash, floatables and debris). Stage 2 is configured to meet the specific removal requirements of the site beyond trash and debris. The individual or combined units can accommodate flows from 1-5 cfs.

A larger system is under evaluation which will address flow rates from 30 cfs to >3000 cfs.

The units are lightweight; easily moved and installed with on-site equipment such as a backhoe or small crane. The units are delivered to the site ready to install with all of the internal fittings manufactured to the customer’s specifications. Even the pipe flange connections are installed. The units can accommodate pipe sizes up to 24 inches down to a depth of 10 feet.

Disinfection System

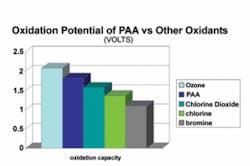

Fresh Creek and Enviro Tech Chemical Services are currently evaluating a stabilized form of peroxyacetic acid (PAA) in application tests for use in both CSO and stormwater outfalls in the U.S. as an alternative to chlorine-based chemicals.

The chemical is commonly called Peracetic acid or PAA, and is trademarked Perasan®. It is manufactured by Enviro Tech. The product is a combination of acetic acid and hydrogen peroxide and is stabilized through a patented process. The broad-spectrum biocide is effective on bacteria, viruses, mold, fungus and yeast. Depending on water conditions, Perasan breaks down to carbon dioxide and water within 30 minutes.

The product is being used in place of typical chlorine or other halogenated chemicals. There are no “cloro” by-products and thus no de-chlorination of the effluent stream. Toxicological data is approved by EPA and an experimental use permit (EUP) for CSO and stormwater systems will be issued in late 2006.

Results are not yet available from the trials, but laboratory results have been encouraging. As little as a few parts per million (ppm) of active peroxyacetic acid can achieve up to a 3 log reduction (99.9%) of total coliform microorganisms in typical wastewater effluent. There is also substantial evidence in literature to verify the efficacy of this material on wastewater microorganisms.

PAA has been used for disinfection outside of the United States for years. In the last 10 years, its use in the U.S. food, beverage and dairy industries has escalated rapidly. It is common to see PAA replace chlorination agents for cleaning and disinfecting pipe, bottles, tanks, etc., in those industries.

The application of PAA at the collection outfall is the ideal point of injection from the standpoint of mixing, contact concentration and time. PAA is infinitely soluble in water and its reaction with bacteria, viruses and pathogens begins immediately. The PAA is fed as a liquid via a pumping or eductor system and is based on PAA demand and flow at the outfall.

It has a shelf life ranging from six to 12 months. The product does not add conductivity to the water, does not form disinfection by-products, and has no RMP, SARA or CERCLA requirement.

PAA degrades within seconds in soil and within minutes in sea water. It is approved for discharge to land and also has NSF approval for use in drinking water. However, it does have specific safety and handling instructions. Reference to Product Data Sheets and MSD’s are essential.