“Modules” Expand Functionality of Control System

A modular water management and simulation system that has been used successfully in Europe has been introduced into the United States by Siemens Water Technologies. The modular components expand on the basic functionality of Siemens’ Simatic process automation system.

During the last decade, many drinking water and wastewater utilities have opted to centralize operational management of their treatment facilities and distribution/collection systems. Using the Simatic WinCC/PCS7, distributed components such as field instruments, PLCs or pump controllers can all be integrated into a centralized process control system.

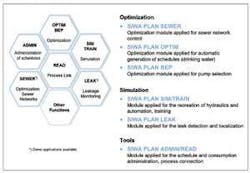

Siemens’ Siwa Plan is a modular system that expands Simatic’s basic functionality to include industry-specific modules that support operational assistance or management tasks.

Siwa Plan uses the Simatic WinCC human-machine interface (HMI) as its system platform and offers two modules for training/simulation (Siwa Plan Sim and Siwa Plan Train), three modules for optimization (Siwa Plan Optim, Siwa Plan BEP, and Siwa Plan Sewer) and one module for leak detection (Siwa Plan Leak).

Training, Simulation

Integrated into a plant’s control system, the Siwa Plan Sim module simulates the hydraulic behavior of pressurized pipe systems and sewage networks as well as the automation technology used under varying operating conditions. Facility personnel can examine possible operating variables and incorporate the findings into managing the actual plant.

The Siwa Plan Train training system is based on the simulation module. It reproduces in detail the actual control system’s operator interface. Personnel can simulate operational problems and responses without any risk to the plant or to themselves. Siwa Plan Train can also train the operating team before changes are implemented at the plant.

Optimization

The Siwa Plan Optim operational management system optimizes pump operation in pressurized pipe systems, such as drinking water networks. It can calculate the most cost-efficient pump operating schedule, based on minimum/maximum daily delivery rates, volumes, times and costs for energy consumption and water production. As shown in a feasibility study for one of the largest water suppliers in Germany, the use of Siwa Plan Optim can result in cost savings of 5% to 8%.

If discrepancies occur between the calculated and actual results, the system triggers an alarm and prompts the user to re-plan. The system can also be used to optimize the import of outside water, maintenance and service work, and power consumption.

Siwa Plan BEP (Best Efficiency Point) mathematically optimizes energy use in pumping stations for drinking water, irrigation and wastewater networks. The system reduces energy consumption by as much as 8% by calculating the optimum distribution of delivery between the individual pumps for a given throughput. The module can handle fixed- as well as variable-speed drives.

The Siwa Plan Sewer module calculates optimum control interventions in wastewater disposal systems. As a stormwater management tool, the module reduces the amount of untreated wastewater discharged from the sewer network into the environment. A special modular library enables the module to be adapted quickly to almost any sewer network.

Leak Detection

The Siwa Plan Leak detection system can detect and pinpoint leaks by using field instrumentation already available in most water and wastewater pipeline networks. Using a combination of various mass balance and pressure techniques, the module detects burst pipes and small leaks as well as gradual water losses. Pressure, flow and temperature are the most important measured variables. The module’s detection algorithms can be used alone or in combination to suit each installation’s individual requirements.

Engineering Toolset

Siwa Plan also includes a standard graphical design tool that provides uniform and consistent data management across all modules, which shortens engineering times by approximately 20% to 30%. For instance, a medium-sized installation can be designed, engineered and installed in approximately four to six weeks.

Conclusion

Siemens’ Siwa Plan training/simulation, optimization and leak detection modules have helped many drinking water and wastewater treatment facilities in Europe optimize their resources, reduce operating costs and boost plant availability. While the modules are fully integrated into the Simatic WinCC/PCS7 process control system, they are also compatible with control and automation technologies from other manufacturers. WW

About the Author

Dr. Andreas Pirsing is senior sales manager of water business for the Industrial Solutions and Services Group at Siemens AG. Dr. Pirsing is based in Berlin, Germany.