Transportable System Provides Drinking Water for Hurricane Relief

The Expeditionary Unit Water Purifier, or EUWP, is a mobile water system capable of purifying, storing, and dispensing potable water in any austere environment - even under conditions of blowing sand, dust and rain, at air temperatures from 32oF to 120˚F - from virtually any water source.

Developed as part of a research program aimed at reducing the costs and energy requirements for desalination, it was designed primarily to fulfill the military’s need for a transportable system to provide potable water to troops in the field, although a variety of other applications are anticipated. In its first real-world missions, it was called on to provide emergency water supplies.

A demonstration unit was deployed to Port Clarence, Alaska, home of the world’s northernmost U.S. Coast Guard station, in July 2005. A series of storm surges had flooded the area’s two lakes, leaving the water too salty to be purified by the station’s own water treatment system. In three days, the EUWP produced approximately 250,000 gallons of purified water - enough to carry the station’s 23 personnel through the Alaska winter.

That, however, was merely a warm-up for the technology’s next challenge, which presented itself a month later.

As two Generation I EUWP systems were undergoing final reliability testing, Hurricane Katrina hit the U.S. Gulf Coast on August 29, 2005. The following week, engineers from the Army’s Tank Automotive Research Development and Engineering Center (TARDEC) and the Bureau of Reclamation (BOR) packed up the units and headed to Mississippi.

One EUWP was set up on the deck of the Hard Rock Casino in Biloxi, with a line running into the Gulf of Mexico. A few hours after the 60-kW diesel generator was started up, the EUWP began converting seawater into potable water. A system of PVC pipe carried the water three uphill blocks from the beach to the Biloxi Regional Medical Center. The system also included taps so neighborhood residents could obtain water.

During its one-month mission in Biloxi, the EUWP provided more than 1 million gallons of water to the hospital, at an average rate of 2,900 gal/hr. It enabled the medical center to operate as a fully functional hospital while its water system was being restored, said Keith Allen, Engineer Administrator and Public Water Supply Director of the Mississippi Department of Health.

When the local utility was once again able to supply water, the EUWP was returned to its temporary home at the Tularosa Basin National Desalination Research Facility to await its next mission.

The other EUWP demonstration unit was dispatched to the Pascagoula shipyard. From there it was ready to provide 100,000 gal/d of potable water to a cruise ship being used in the relief efforts.

Membranes as Workhorses

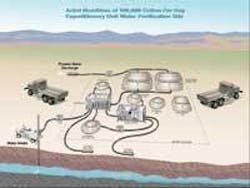

The EUWP consists of an ultra-filtration (UF) membrane process to remove suspended solids, followed by a reverse osmosis (RO) desalination process to remove dissolved solids. Raw water is drawn from a surface or underground source and pumped to the UF module. The filtered water from the UF module proceeds to the RO unit, while the UF reject stream is returned to the source. After desalination, the treated water flows to product storage bladders until it is needed.

The UF process is capable of treating highly turbid source waters (up to 150 NTU), while the RO process can treat highly saline source waters (up to 60,000 milligrams per liter of total dissolved solids). The EUWP can also treat a source contaminated by nuclear, biological or chemical (NBC) agents using a double-pass RO configuration. When desalination is not required, the UF module can be deployed independently of the RO module.

The EUWP system has about a 36% recovery rate, meaning that of every 100 gallons entering the system, 36 gallons of pure water exit the system. The recovery rate for the UF system when used alone is 80%.

For some source waters, conventional water-treatment additives may be required, such as ferric chloride as a flocculent to aid the filtration of the water in the UF system, and/or anti-scalants to prevent scaling on the RO membranes.

Reverse osmosis was selected as the core technology for the EUWP because of its ability to desalinate water with a wide range of salinity and its effectiveness against most water contaminants, including NBC agents. In addition, RO requires less energy to desalinate seawater than technologies such as distillation and electrodialysis. RO systems also tend to be lighter weight than other desalination technologies. This is a critical consideration for mobility, particularly by air transportation.

Lightweight, Mobile

The Generation I EUWP Demonstrator, which can produce about 100,000 gal/d from a seawater source, or more than 200,000 gallons per day of potable water from a fresh water source, includes supplies for 100 hours of operation, 40,000 gallons of product water storage, and a 60-kilowatt generator. A team of four water treatment specialists can have it set up and producing potable water within six hours. The unit can operate unattended with only periodic preventive maintenance, or it can be converted to a completely electric-powered system for extended-duration missions.

The EUWP is designed to be transported on a C-130 aircraft, which fixed the allowable size and weight. The system consists of two separate 8x8x20-ft ISO configured platforms and weighs less than 35,000 lb.

Because minimizing weight was a major objective, Village Marine Tec. (Gardena, CA), which developed the Generation I Demonstrator, selected pumps made of fiberglass-reinforced plastic (FRP). An FRP pump weighs approximately 25% of the equivalent carbon steel pump.

“If the EUWP weighed too much, the range of the C-130 would be reduced because it would have to take less fuel to account for the weight. Using FRP pumps allowed the EUWP to come in under the target weight,” explains Mike McCain, business manager at Village Marine.

The EUWP system employs six FRP pumps. A self-priming close-coupled pump serves as the raw-water feed pump, while the other five are ANSI close-coupled pumps. The feed pump, which is designed to have vertical lift of 25 ft on a 50-ft inlet, draws raw water from the source. A UF booster pump at the inlet of the UF skid then forces the water through the 200-micron strainer and into a tank.

The UF feed-and-cleaning pump transfers the strained water from the tank, through the UF filter system, and into another tank. This dual-duty pump is used both to fast-flush the UF cartridges and to circulate water during the UF cleaning cycle; during the back-flush cycle, a separate UF back-flush pump forces large volumes of water through the UF cartridges on a periodic basis.

Water is pulled from the second tank by the RO feed pump and fed to the RO skid. This is also a dual-duty pump and is used in the RO and UF cleaning cycles. Finally, the RO product-water pump pulls potable water from the storage tanks and sends it to the user(s).

About the Author:

Gennaro A. D’Alterio is sales and marketing manager at the Dean and Fybroc Divisions of Met-Pro Corp., Harleysville, PA. He was graduated with a B.S. M.E. and an M.B.A. from Villanova University. D’Alterio has been involved with specifying and applying centrifugal pumps and technology for a wide variety of applications in many different industries for the past 15 years. Since joining Met-Pro he held a number of positions, including applications engineer and regional manager for both corporate divisions.