Condition assessment: A core component of any anti-corrosion program

Located in Jackson Wyoming, Spring Creek Ranch has several miles of underground pipe in a water system that is separate from the City of Jackson. The potable water from their wells is the primary source for many residences as well as short and long-term luxury lodges. To ensure these customers continue to receive quality water, the resort has embarked on a non-invasive pipe condition assessment project to ensure their water mains are, and remain, in good condition without causing any service disruptions to their guests and residents.

The Resort chose Echologics to survey 1.7 miles of 12-inch ductile iron pipe, utilizing the ePulse method to assess the condition of the over 40-year-old pipes. Most corrosion in metallic pipes is caused by a combination of internal and external corrosion, soil aggressiveness and coating defects on the surface of the main.

The selected pipes were from the primary water main starting from the wellhead to the on-site storage tank.

The mains span over 1.5 miles and climb an elevation difference of 1,200 feet through a remote trail before they reach the resort.

From there, the main travels through part of the resort, including Lower Harvest Dance Road, to the on-site storage tank as illustrated to the left in Figure 1.

Pipeline assessment

The technology uses acoustic wave propagation to measure the remaining structural pipe wall thickness. Non-invasive and non-intrusive, this technology enables rapid inspection of large areas of a water distribution network without removing the pipelines from service, avoiding service interruptions, pipeline dewatering/cleaning, or large costly excavations.

The method works by measuring how quickly acoustic signals are transmitted along a segment of pipe. Acoustic signals are induced in pipes by lightly tapping on appurtenances in a controlled manner. The sound is recorded using acoustic sensors positioned at two points on a pipeline. The sensors are attached at easy-to-access appurtenances, or directly on the pipes.

The acoustic propagation velocity is calculated based on the sensor spacing and time delay between the measured acoustic signals. The average wall thickness of the pipe segment between the acoustic sensors is then back calculated.

The technology combines acoustic data with pipe material information to calculate its current structural wall thickness. The pipe’s material, internal diameter, and modulus of elasticity are all critical variables in this calculation. The percentage of structural wall thickness loss is calculated by comparing the measured thickness to the nominal thickness.

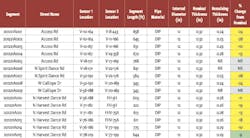

The results presented in Table 1 show that all the pipes tested were in moderate condition (change in wall thickness between 10% and 30% from nominal, in yellow) except for one segment which was identified to be in good condition with a 9% change from nominal, in green.

However, some segments that are identified to be in moderate condition are approaching the poor condition category (greater than 30%) with changes from the nominal wall thickness of 24%, 28%, 24%, and 28% respectively. The results represent the average remaining structural wall thickness over each test segment and therefore may include smaller lengths pipe with greater levels of degradation within each segment.

Three segments yielded no results, in grey, which could be due to factors attributing to poor sound propagation along the segment. These segments were longer than the recommended spacing for the ePulse method, which likely prevented the acoustic wave propagation to travel the entire length of the segment. Results may be obtained on these segments in future re-testing by adding potholes for additional sensor access points.

Stephen Price is the General Manager and Owner of Spirit Dance Hotels & Resorts. Following his and the shareholder’s review of the final report, he stated “On a very positive note, no leaks were detected and the assessment was completed in a couple of months. The technology was easily implemented without the need for external traffic control and without interruption to service or disruptions to our customers.”

Turning Data into Action

The utilization of evidence-based condition assessment data is a proactive approach to asset management. It can extend the lives of water mains by distinguishing those that are merely old from those that are truly impaired and allow asset managers to prioritize limited renewal budgets to the assets that require it the most. The Resort may also consider pipe rehabilitation as an option to reduce costs associated with water main replacement.

For pipes that are in good condition, the common industry practice is to perform follow-up condition assessment testing in approximately 10 years depending on the consequence of failure to determine the rate of change of condition with time.

Pipes that are in moderate condition, should be monitored according to the criticality of the main. The utility may also consider some of the following options:

- For mains without an internal lining, cleaning and lining can often extend the life of moderate condition mains as well as adding cathodic protection.

- Regularly scheduled, traditional leak detection surveys. This is a relatively inexpensive option capable of finding many leaks within a system. However, this method can be labor intensive and may not prevent catastrophic failures on high consequence pipelines.

- A permanent leak monitoring system, like the EchoShore-DX® can find most leaks on a pipeline including small leaks that are not easily picked up with traditional listening devices. The system can check for leaks nightly to detect and notify the operations staff of small leaks before they turn into catastrophic failures.

- A follow-up condition assessment survey to measure the rate of decay in 5 years depending on the consequence of failure. A desktop analysis, such as PipeRankÔ may be utilized to prioritize which pipes have the highest likelihood of failure to determine the best candidates for future condition assessment surveys.

“This first trial run of the new technology has gone really well, and we plan to further our condition assessment using ePulse over the next two years to ensure quality drinking water supply for the residents and visitors of Spring Creek Ranch,” concluded Mr. Price.

About the Author

Malay Patel

Malay Patel is senior manager, capital projects for Mueller water products.