Pipe Rehabilitation and Trenchless Pipe Repairs for Urban Environments

INTRODUCTION

The responsibility for repair and maintenance of pipelines is borne by the entity that installed it in the first place. Major pipelines such as interstate aqueducts may be the responsibility of the federal or state governments. Regional storm sewers, sanitary sewers, and water supply mains are managed by county and city governments. Utility service lines (gas pipelines, electrical power transmission lines, telephone, cable TV, internet, etc.) are maintained by the utility in question. Commercial service lines and pipelines of all kinds are usually installed and repaired by the businesses and property owners that installed these connections, as are homeowners and individual business owners.

All of the above have one thing in common: the desire to save money by minimizing the costs of repair, maintenance, and rehabilitation. It’s important to note that maintenance and repair are two different things. Maintenance is performed to minimize the odds of having to perform repairs, and is performed at regular planned intervals. Repair is unscheduled and performed when necessary. Rehabilitation, on the other hand, is another thing entirely: the act of restoring something to its original state. When age or physical damage require it, pipe systems can need a complete rehabilitation instead of standard maintenance or necessary repairs.

Because they are often buried, pipelines are sometimes out of sight and out of mind. And while age is a general indicator of pipeline health, there really is no way of accurately predicting which section of pipeline will go bad at any given time. So, while pipeline maintenance is performed on a regular basis, and the observations made during these operations can provide valuable information concerning the current state of the pipeline, pipeline repairs and rehabilitation are, by definition, unpredictable.

The need for effective, non-obtrusive pipeline rehabilitation occurs more often in urban environments than in rural areas. While pipes can fail or get damaged in the country, there density-per-area is much less than in high-population cities, and the effects of traffic, equipment vibrations, construction, and other impacts is minimal by comparison. Also, in rural areas there is simply more elbow room to perform pipe rehabilitation and repair work. Methods that minimize the impact of these operations on surrounding activities and infrastructure are not usually necessary.

When pipe work occurs depends on the type of work in question. Pipe maintenance is performed on a regular schedule, one driven by both physical demands and budget constraints. Repair happens as needed, usually in the form of emergency repair work to get a damaged utility back on line and in service. Budget money will be found in any case; utility managers and their customers simply have no choice.

Rehabilitation, on the other hand, usually occurs at the end of a long cycle of a pipeline’s operational lifetime. Evidence of age and decay of a pipeline accumulates with each repair cycle and can be estimated from field observations concerning the state of the utility in question. Given the long-term projections from field data, industry standards, and manufacturer’s material information, money for this work can often be budgeted for ahead of time via increased taxation or by floating development bonds.

There are many reasons why pipeline rehabilitation is performed. First and foremost is the status of our nation’s crumbling infrastructure. A recent (2013) study performed by the American Society of Civil Engineers (ASCE) estimates that an investment of $3.6 trillion will be needed by 2020 to restore what is basically the foundation of our country.

“At the dawn of the 21st century, much of our drinking water infrastructure is nearing the end of its useful life. There are an estimated 240,000 water main breaks per year in the United States. Assuming every pipe would need to be replaced, the cost over the coming decades could reach more than $1 trillion, according to the American Water Works Association [AWWA].”

As for our wastewater sewer systems, “Capital investment needs for the nation’s wastewater and stormwater systems are estimated to total $298 billion over the next 20 years. Pipes represent the largest capital need, comprising three quarters of total needs. Fixing and expanding the pipes will address sanitary sewer overflows, combined sewer overflows, and other pipe-related issues. In recent years, capital needs for the treatment plants comprise about 15% to 20% of total needs, but will likely increase due to new regulatory requirements. Stormwater needs, while growing, are still small compared with sanitary pipes and treatment plants. Since 2007, the federal government has required cities to invest more than $15 billion in new pipes, plants, and equipment to eliminate combined sewer overflows.”

In addition to the projected massive capital costs required to restore our pipe systems, the current poor state of our pipelines results in the hemorrhaging of operational costs due to non-revenue water loss and pollution to groundwater and surface water from our leaking sanitary sewers. Non-revenue water loss takes place when water is lost somewhere between the source of the water and the water consumer, usually due to leakage.

These are physical losses caused by leaks, breaks, and spills. And relatively small but continuous amounts of lost water can eventually add up to significant lost revenues from customers and a financial burden on the water utility. These same leaks that lose water can also provide an entryway for contaminants that would harm the water’s quality and endanger public health—especially if the water supply line is co-located along with a leaking sanitary sewer pipeline.

THE PIPE REHABILITATION ENVIRONMENT

As mentioned above, it is urban areas, not the rural countryside, that typically need the techniques of pipe rehabilitation. The reasons for this are the confined conditions found in cities. These constraints are both horizontal and vertical.

Horizontally, pipe rehabilitation work is constrained by the need to avoid blocking traffic flows, both vehicular and pedestrian. While automobile traffic can be detoured and sidewalks closed to people, it is often necessary for reasons of safety and commerce to keep these arterials moving as much as possible. Automobile traffic especially represents a significant safety issue that can be avoided with a smaller work footprint at the surface. Buildings and other infrastructure such as bridges, and sign, power, and communication posts, will also limit horizontal freedom of movement.

Vertical constraints occur both above and below the work area. Overhead, electrical-power lines and phone and cable TV lines limit the operating height of the equipment used on the site. Below, the city’s ground surface is a system of sometimes poorly mapped pipelines that can interfere with attempts to perform pipe rehabilitation. The sewer pipe or water main that needs work will often be surrounded by steam lines, telephone and TV cables, other water mains, sanitary sewers, and storm drains. These utilities can run parallel or even crisscross the pipeline that needs work, above or below it. If above, it presents a physical impediment to accessing the pipeline. If below, it can be damaged by impact loads from the work above it.

But to get through the surface itself often requires sawing, cutting, and digging through concrete or asphalt pavements. In addition to curbing that can consist of 4- to 6-inch-thick concrete, pipelines can run under paved surfaces designed for urban traffic, ranging from 45,000 vehicles per day for major arterials, to less than 1,000 vehicles per day for local streets. Pavements for industrial roads and major arterials can consist of 8-inch-thick, rigid, reinforced concrete overlaying a 6-inch-thick stabilized subgrade. Local streets can have a 2-inch thick flexible bituminous concrete pavement overlaying a 6-inch base of compacted stone over a 6-inch subgrade. Of the various types of pavement encountered, reinforced concrete represents the most challenging to cut through, due to the reinforcing steel rebar.

THE CHALLENGES OF PIPE REHABILITATION

The first challenge to pipe rehabilitation is the fact that the pipes themselves may be difficult to find. The lack of complete records, especially for older city neighborhoods and industrial areas with private utility lines, may result in a knowledge gap concerning the pipe’s depth, diameter, materials, slope, and alignment. Even if the pipe’s depth and location were known, it may be at such depth that an open pit excavation to expose the damaged portion of the pipe may be prohibitively expensive or too difficult to access.

Cutting off service to the pipeline, or temporarily bypassing its flows under repair is usually inevitable during rehabilitation operations. However, the crowded underground environment of urban areas will include other utilities whose service may be disrupted or shut off completely by a large open excavation. Buried electrical power lines, in particular, present a significant hazard, requiring extensive safety procedures, clearance, lock out and tag out, etc.

The extent and type of repair work (joint offsets, root intrusions, severe cracking, or other defects) necessary to rehabilitate a pipe may not be apparent until it is exposed by excavation. This would, at first glance, seem to argue in favor of open-fit access. However, the use of underground utility detection technologies—such as metal detectors, ground-penetrating radar, passive sound detection, GPS locators, and close-circuit pipeline TV cameras—can also be helpful.

Metal detectors are used to find iron, steel, and copper water lines, metal gas lines, copper and aluminum electrical wires, steel structural cables, and telephone and TV cables. Ground penetrating radar uses an electromagnetic (radio wave) antenna tuned to a frequency that can penetrate soils, rock, concrete, ice, and other common natural and manmade materials, allowing for the creation of a three-dimensional underground survey of the work zone. Passive sound detectors use a sensitive ground microphone to listen for the noise of a water leak transmitted along pipes, valves, and hydrants and through the ground. GPS systems can be used to precisely determine the location and alignment of utilities, while CCTV cameras can run the length of a pipeline looking for physical damage that needs rehabilitation.

All of these methods can be used to accurately locate areas in need of rehabilitation and should be considered integral to trenchless pipe rehabilitation techniques.

ADVANTAGES AND COSTS OF TRENCHLESS PIPE REHABILITATION

All pipe rehabilitation projects will include the costs of preliminary sewer cleaning and inspection. There are several site-specific factors that will determine the overall cost of trenchless pipe rehabilitation. These include: the length, depth, and diameter of the pipe; the types of defects needing correction; pipe bends and changes in grade; the number and locations of potential access points such as manholes or clean outs; the number and location of nearby utilities and other pipelines; the number of fixtures and appurtenances that need to be replaced in the course of rehabilitation; the costs of shutting off service or providing temporary bypass hoses or pipelines; and (most importantly) the amount of excavation required for access to the pipeline.

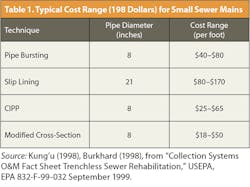

All other factors being equal, the need to cut through pavements and dig through and around adjacent utilities is a major cost item for any rehabilitation project. It’s this excavation cost that drives the need for trenchless pipe rehabilitation in the first place. Almost anything that can be done to prevent the need for extensive cut trenches that follow the entire length of the pipe to be rehabilitated would represent a significant savings in time and money. Typical cost ranges for several types of trenchless pipe rehabilitation projects are provided below (based on actual projects):

for a pipe repair n Haines City, FL.

METHODS OF TRENCHLESS PIPE REHABILITATION

Sometimes only a light touch is needed. Pipe cleaning and root cutting operations are fairly standard pipe repair and rehabilitation operations. Pipes will tend to clog over time and will require either physical flushing with powerful jets of water, or chemical cleaning to remove or neutralize impurities. Root cutting can be done from within the pipe by use of a hydraulic root cutter inserted along the length of the pipe. The root cutters spinning blades chop off the roots and grind up vegetation allowing it to be fused out of the pipe.

A relatively simple approach is chemical grouting applied to spot repairs. Typical grouts are acrylamide and urethane that are injected under pressure directly into the failed part of the pipe (leaking joints, wall cracks, etc.). This is not a method typically useful for extensive repairs such as broken and dislocated pipe or crumbling pipe walls, but it gets the job done for small, discrete repairs on pipes larger than 6 inches in diameter. While under pressure, the grout fills and expands the failed space and pushes outward to the surrounding soils adjacent to the failure. The grout then forms a seal with the soil bonding to the pipe wall.

Sometimes a new pipe interior wall is called for. That is where cured-in-place liner pipe (CIPP) techniques can be used. CIPP relines the entire length of the pipe needing repairs with a tube of resin-impregnated fabric. The resin is typically polyester, epoxy, or other thermosetting resin. Application of heat cures this material, bonding the fiber and resin to the pipe’s interior wall, providing a rigid repair seal. The result is, effectively, a new pipe inside of the old with its own structural capabilities and surface qualities. Several sizes of fabric tubes are available for any pipediameter, and fabrics can be made to fit non-circular pipes. CIPP fabrics can be inserted directly or pulled through by a winch.

Several types of materials are used: non-woven polyester felt, woven hose, and membranes. Coated with elastomers, felt can be strengthened by reinforcing fibers. Woven hose is used in pressurized force mains with localized corrosion and leakage. Membranes are usually used for low-pressure gas mains or non-structural sewer rehabilitation. CIPP allows for fast installation with minimal or no excavation required if entry is made from a conveniently large manhole or lift station. The material used usually has a lower surface friction coefficient than the pipe it is repairing, allowing for greater flows even with reduced diameters. However, extensive cleaning, rooting, and preparation are required for the interior of the pipe prior to installation. And CIPP is often applicable only to pipe sizes between 4 and 24 inches.

The technique of fold and formed liner pipe (deform and reform liner pipe installation) requires a polyethylene (PE) or polyvinyl chloride (PVC) liner that has been properly heated and folded to proper size at the factory prior to delivery onsite. It is folded in half, and then in half again, until it is the proper size for insertion. The folded liner pipe is then winched through the length of the pipe being repaired. Once in place, a device is passed through the folded interior, heating and expanding the liner until it assumes the shape of the pipe’s interior. PE is preferred for pressure pipes and PVC for gravity flow sewers. The liner material provides a reduced surface friction coefficient, increasing flow rates, and does not require any grout or applied resin. The material is easy to cut (by remote control) to allow for insertion of appurtenance and branch pipes. However, care must be taken to ensure that the folded pipe completely expands along its whole length without residual folds or wrinkles. It also does not negotiate pipe bends well.

Slip liner pipe technique is similar to the fold and deform method, but it allows for simpler installation. Slip lining involves the insertion of continuous or jointed sections of pipe. High-density polyethylene is a favorite material. Its pipe lengths can be joined by fusing adjacent pipe ends together to form a joint stronger than the pipe itself. When PVC pipe segments are used, they are joined by pushing together belled ends. The slip-lined pipe segments are usually much smaller than the pipe they are being inserted into to allow for ease of installation. Afterwards, the void between the two is usually filled with grout to maintain structural stability and pipe rigidity. Again, the smaller diameter of the new pipe does not experience reduced flows since the slip-lined pipe material has a much smaller surface friction coefficient. This method allows for quick installation in live lines so that bypass pumping is not necessary. However, on the surface this requires a relatively long lay down, where each pipe segment is joined during the insertion process, and care must be taken to ensure complete grouting of the void space to prevent any structural weak spots.

A more dramatic technique than slip lining, pipe bursting, in effect, destroys the previous pipe to make way for the new. This method uses a pneumatic, hydraulic, or static bursting tool to force an in-place expansion of rigid pipe until its walls crumble and are pushed further out beyond its original diameter. Patented by the British Gas Company in 1980, it has been extensively used in the gas industry ever since. Using the inside of the existing pipe as a guide, the expansion head of the bursting tool is pulled through with a cable rod and winch. While traveling along the inside of the pipe, it pushes outwards until the pipe cracks and crumbles. The pieces are then driven deep into the surrounding soil to further expand the diameter of the newly created void space. Increases of 30% are possible with this technique, depending on soil conditions and the type of bedding used by the older pipe. The new pipeline is attached to the end of the bursting device and is pulled through the old pipe as one long continuous length, as the bursting tool advances along its length. This allows for preparation and installation in one easy step. As simple and direct as this method is, it does require that all branch pipes and appearances within 3 feet of the pipe be excavated and exposed, so they are not damaged as well. As a brute force method, it does not require refinements such as pre installation pipe cleaning. It also allows for the installation of a large pipe.

The following table provides comparisons of the pipe rehabilitation methods described above (along with some variations).

EPDM = Ethylene Polypelene Diene Monomer

GRP = Glassfi ber Reinforced Polyester

HDPE = High Density Polyethylene

MDPE = Medium Density Polyethylene

PE = Polyethylene

PP = Polypropylene

PVC = Poly Vinyl Chloride

PVDF = Poly Vinylidene Chloride

INNOVATIVE APPLICATIONS OF PIPE REHABILITATION TECHNOLOGY

Pipe breaks that occur adjacent to prior repairs are a recurring problem in the water industry. These often happen due to pipe movement caused by ground shifts and temperature changes. Krausz’s repair products help ensure water and wastewater piping systems remain durable even within the harshest of conditions. The company’s HYMAX products feature a patented, progressive, pressure-assisted gasket that allows dynamic deflection of up to 4 degrees per side. This flexible connection helps prevent post-installation pipe damage. Once installed, Krausz products become a permanent part of the pipe that can reliably withstand severe environmental conditions.

Since 1994, QuakeWrap has been a leading designer, supplier, and installer of quality, innovative fiber reinforced polymer (FRP) products for repair and strengthening of

structures. Their FRPs are made up of flexible fabrics composed of carbon or glass fibers, a high-viscosity tack coat, and a saturating resin that provide a fast an inexpensive method of pipe rehabilitation. The FRPs used by their StifPipe system are used in structural strengthening as well as in protecting against moisture intrusion and corrosion.

Dr. Mo Ehsani invented the StifPipe system, which has the 2016 American Society of Civil Engineers (ASCE) Innovation Award in the category of “Green Engineering.” “StifPipe can be easily manufactured to any shape or size, will not corrode, and weighs about 10% of conventionalpipes. The walls of StifPipe consist of a lightweight honeycomb core covered with carbon or glass FRP, a technique that has been successfully used in the aerospace and ship-building industries for decades,” says Ehsani. StifPipe has been used to repair deteriorated pipes and culverts in both the US and Australia, and resulted in significant cost reductions when compared with traditional repair methods.

QuakeWrap has developed a Mobile Manufacturing Unit that allows continuous onsite construction of this pipe at a rate of two miles per week. In addition, its InfinitPipe offers the industry the first sustainably manufactured pipe that will significantly reduce the carbon footprint of future pipeline projects. The StifPipe system provides the ability to build the pipe onsite, is made from lightweight materials, can be manufactured at a fast production rate, and use recyclable materials that are durable and environmentally safe—making it both an innovative and sustainable product. Ehsani states that “with many construction projects trying to achieve LEED certification, the use of StifPipe can contribute significantly towards achieving such certification on pipeline projects.”