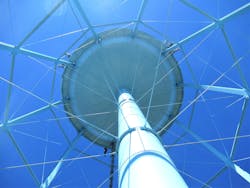

An iconic water tower dedicated to actor Andy Griffith, in the heart of Mount Airy, N.C., has received a major exterior restoration. The landmark welcomes visitors to the real-life Mayberry, and features a pair of familiar silhouettes fishing on the face of the tower.

Standing about 140 feet in the air across the street from the house where Griffith spent his youth, the 500,000-gallon elevated tower has celebrated the actor’s fictional TV hometown — The Andy Griffith Show’s Mayberry — since 2003. The tower’s highly recognizable logo was designed to help boost Mount Airy’s tourism business by striking chords of nostalgia and reminding visitors of the city’s reputation as the inspiration for Mayberry. But, since the logo’s last restoration in 2014, the artwork had become discolored and suffered some weather damage, setting the stage for a late 2020 rehabilitation of the water tank’s exterior and its renewed reminder of Mount Airy’s charms.

‘Oh, What a Spot for Whistling Like a Fool’

Aside from the minor color fading and some superficial spots of rust on the tower, the originally applied coating system was still in great shape in terms of corrosion protection and adherence to the tower’s steel substrate. Therefore, the City of Mount Airy was able to save the high cost of performing a complete rehabilitation in favor of applying an overcoat system to the tower before recreating the iconic logo. That meant contractors would not have to blast the tower down to bare metal and apply a full three-coat system, saving time and budget.

“The tower had scattered areas of coating deterioration such as adhesion failures, corrosion, blisters, and chalking — all of which was to be expected after several years of ultraviolet (UV) and weathering exposure,” says Carl Lynn, project manager for Southern Corrosion Inc. “But it was still a prime candidate for an overcoat system, which was a welcome budget saver for the community.”

With the tank located right in a residential neighborhood, applicators from Southern Corrosion needed to be careful to prevent any debris and coatings overspray from escaping and landing on houses and vehicles. That meant opting for surface preparation methods and coatings that minimized this potential.

“‘Don’t paint the houses and don’t paint the cars’ is always top of mind when applying coatings to water towers,” says Lynn. “That meant protecting various structures and objects with cloth and plastic, as well as using the weather to determine our daily goal. Now and then, we had to wait for the right wind and right temperatures to proceed.”

Following surface preparation, the crew applied Macropoxy® 920 PrePrime to the affected areas at 1 to 1.5 mils dry film thickness (DFT) to lock down the existing remaining coating and provide a sound substrate for the new coating system. The product is a two-component, 100 percent solids-penetrating epoxy primer that delivers the benefits of a penetrating sealer for tight rusted surfaces, along with low viscosity and low volatile organic compounds (VOCs).

Next, applicators used Macropoxy 646, a two-component, high-solids, fast-drying polyamide epoxy to protect the rehabilitated areas with durable, long-term corrosion protection. Crewmembers applied both coatings carefully, using brushes and rollers, rather than sprayers, to avoid any potential issues related to overspray landing on nearby houses and cars.

Applicators then used Sher-Cryl™ HPA as the topcoat for the entire tank, as well as for recreating the iconic Mayberry-inspired logo. The coating has dryfall and other application characteristics that made it an ideal choice. Applicators applied the topcoat at 2 to 3 mils DFT, spraying it on without worry that any overspray would stick to houses and cars because the fast-drying droplets would be solid by the time they landed.

“We often use dryfall coatings when working in high claim areas, such as in city centers, next to car dealerships and near highways,” notes Lynn. “The added insurance of any overspray not being able to stick to valuable assets takes a lot of pressure off the applicators.”

For recreating the iconic logo, which was originally applied by award-winning artist Jeremy Sams from Archdale, N.C., an applicator from Southern Corrosion handled the free-hand application using the same acrylic Sher-Cryl HPA coating. As a single-component, ambient-cured coating, the product created no worries for the applicator related to pot life or catalyzation. He could simply pop open a can, stir it, apply the coating, and then reseal the can when done — a necessity when performing detailed hand work 140 feet in the air.

‘I Can’t Think of a Better Way to Pass the Time of Day’

“Southern Corrosion has been a wonderful company to work with in taking care of our tanks and other infrastructure. They’re prompt and, when they schedule a project, they get it done,” says Mitch Williams, Public Works Director for the City of Mount Airy. “In addition, Sherwin-Williams has always been an excellent partner in handling our industrial coatings needs from color matching to assessing the conditions of our assets and providing recommendations for improvements.”

For the water tower exterior project, Sherwin-Williams offered support services from a nearby store. Being able to deliver materials to the project site and store excess materials close by instead of on-site helped reduce inconveniences in the mostly residential area surrounding the tower and helped Southern Corrosion complete the restoration in a timely manner.

‘Meet Me at the Fishing Hole’

By the end of the three-week project in October 2020, applicators had used roughly 200 gallons of Sherwin-Williams Protective & Marine coatings to restore the iconic water tower exterior. Their efforts earned the project team an honorable mention in the 2021 Sherwin-Williams Impact Award program, which honors projects featuring high-performance coatings from Sherwin-Williams Protective & Marine.

Now, above the intersection of Haymore and Rockford streets, Mount Airy’s highest tribute to Andy Griffith proudly greets residents and visitors once again, inviting them to meet at the water tower and revel in the city’s storied history. WW

Published in WaterWorld magazine, November 2022.