Enhanced Polyethylene Takes Polywrap a Step Further

Polywrap has been a proven way to protect ductile iron pipe from exterior corrosion for many years. Polywrap is simple: it’s a polyethylene sleeve that is pulled over the ductile iron pipe at the time of installation to create a barrier between corrosive soil and the pipe.

Recent advances in the polywrap industry have resulted in the development of Enhanced Polyethylene, making this already very cost-effective, efficient and proven method even more effective. Enhanced Polyethylene still creates a barrier between the pipe and the soil but it also has other, more advanced forms of protection to further combat a wider range of different types of corrosion.

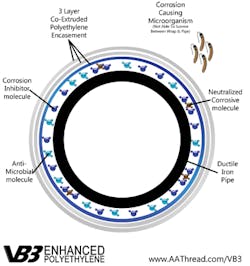

AA Thread’s VB3 Enhanced Polyethylene is a three-layer, co-extruded film made from only virgin polyethylene.

AA Thread’s VB3™ Enhanced Polyethylene is a three-layer, co-extruded film that is 8 mils thick and made from only virgin polyethylene. It is also infused with two different active corrosion fighters: an antimicrobial additive, and a volatile corrosion inhibitor (VCI).

The antimicrobial additive fights against sulfate-reducing bacteria and other corrosion-causing microorganisms. The VCI will neutralize any corrosive liquid that may seep between the wrap and the pipe. AA Thread has spent many years making sure its VB3 Enhanced Polyethylene is produced to the highest standards possible and proven to be effective in these areas, sending out the film for testing by independent labs to ensure the antimicrobial additive and the VCI were proven effective. Tested against a number of different types of bacteria, VB3 was proven to be over 99.9% effective in bacteria reduction.

VB3 has also been tested to ensure the VCI is doing what it should. Several samples of standard polyethylene as well as several samples of the VB3 Enhanced Polyethylene were placed in containers with a corrosive solution and a plate of metal. The metal in the dishes with the standard wrap had high levels of oxidation/corrosion forming after seven days. The metal in the dishes with the VB3 Enhanced Polyethylene had zero oxidation/corrosion.

In addition to these tests, VB3 Enhanced Polyethylene also meets or exceeds all the ANSI and AWWA C105 standards in place for polywrap, making it the most advanced and enhanced product on the market.

For more information about AA Thread Seal’s polywrap products, call (800) 537-7139 or visit aathread.com/VB3.

Circle No. 247 on Reader Service Card