Making the Case for Stainless Steel Service Piping

Tokyo and Taiwan have enviable leakage levels thanks to stainless steel water service pipe replacement programs. This article looks at the rationale behind the investments and the case for molybedum use in steel.

By Alan Hughes

On average more than a quarter of the water distributed by utility companies never reaches a single customer. Leakage from old pipes and broken fittings is mostly to blame. In Europe, an average of 26 percent of water is lost; in other parts of the world, Non Revenue Water (NRW) rates of up to 70 percent have been recorded. In the US, two thirds of a $384 million, 20-year capital investment program for public water systems has been earmarked for improvements in water distribution systems.

Near-zero leakage in Tokyo

Like any city, Tokyo uses a lot of water. Rapid economic growth in the second half of the twentieth century greatly increased water demand as an influx of population and industries swelled the metropolitan area. Even though demand has slowed thanks to new water-saving technologies, the city still has an incredible thirst.

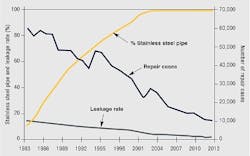

The potential for leakage in a network with more than two million connections in one of the seismic hotbeds of the world is massive, yet water loss is only a little over 2 percent. The reason is that in the early 1980s, the water authority began a water loss reduction program to replace all the lead service piping in the network with Type 316L stainless steel, and since 1998, with corrugated Type 316L stainless steel pipe. They also replaced the cast iron water mains with seismic-resistant ductile iron piping, reducing the vulnerability of the transmission infrastructure to earthquakes.

The authority furthermore introduced a comprehensive leak detection and fast repair regime, using a variety of new technologies to detect and fix leaks very quickly, often before they become apparent. This increased vigilance, coupled with the replacement program, saw Tokyo’s NRW fall from 17 percent in 1983 to 2.2 percent in 2013. To put this into context, Tokyo has reduced annual water leakage by nearly 150 million cubic metres since the early 1990s.

The cost savings associated with the reduced water loss combined with the savings due to the drop in repair cases amounts to hundreds of million dollars in cost savings per year for the Tokyo Water Works.

Drought averted in Taiwan

A similar program to replace service piping and cast iron mains was undertaken in Taipei, where the water department distributed 800 million cubic metres of water in 2013, over a network with some 310,000 connections. The program began in 2003 after a severe drought in the previous year which brought intermittent water supplies to the Taiwanese capital over a 49-day period.

Leakage rates were analyzed in 450 district metering areas within the city, revealing that 40 percent of the areas were losing half of their water or more before it reached consumers. A detailed analysis of the repair cases showed that while poly butylene pipe accounted for only 3 percent of the network it had 28 percent of all leaks. Some 90 percent of all problems occurred in plastic pipes, with the vast majority (83 percent) caused by cracking. As in Tokyo, an enhanced regime of leakage detection and swift repair was introduced.

The ongoing program has so far replaced 35 percent of service piping of various materials with corrugated Type 316L stainless steel pipe. The result so far is a 10-percentage point drop in water loss from 27 percent in 2003 to 17 percent in 2014. In terms of water volume, losses in Taipei were even greater than in Tokyo, at 365 million cubic metresin 2005. In 2014, with the replacement program less than half complete, leakages had already been reduced to 219 million cubic metres, a reduction of 146 million metres, resulting in significant cost savings.

More significantly, a drought more extreme than the 2002 event which precipitated the pipe replacement program occurred in 2014, with 13 percent less rainfall than during the previous drought. However, the vast improvement in leakage rates achieved since 2003 meant that there was no interruption to the water supply, in fact more water reached the customers even though less was distributed in total.

These examples illustrate the impressive savings in leakage, lost revenue and repair budgets which can be accrued with a service piping replacement program based around molybdenum-containing stainless steel. Water is a fundamental human need which can’t be substituted with anything else and security of supply is a prerequisite for sustainable growth. Long-term capital investment programs such as these represent an investment in the future, but also make economic and environmental sense in the present day.

Durable and resilient service piping

Upgrading ageing steel, lead or plastic water pipes can dramatically reduce water leakage, particularly in the service pipe connecting the water main to a property, where some 95 percent of leaks are typically found. Problems often go undetected for months or years, meaning that even small leaks can be responsible for the loss of millions of liters.

Replacing old pipes is the obvious solution, but with what? To provide hygienic drinking water over a long service life, pipes must be manufactured from a material offering several distinct advantages over the steel, iron and plastics versions they are replacing.

Corrugated stainless steel piping dispenses with the numerous elbows and fittings needed in traditional pipes to connect the water main to the meter. These joints are vulnerable to the aging of gaskets, earth movement and vibration from traffic, all of which can cause them to leak over time. Using corrugated stainless steel piping has been shown to reduce the potential for leaking by 75-80 percent.

Molybdenum-containing stainless steel is an ideal replacement material for older pipes made from lead, iron or plastics. It can dramatically reduce the number of repair cases and overall water loss, especially in areas with frequent seismic activity where the risk of damage to underground piping is greater.

###

- Alan Hughes is a senior associate at Stratia and represents the International Molybdenum Association (IMOA).