Utility Tests New Sludge Digestion Process

By Jeff Guild

Municipalities use a wide variety of methods to digest and dispose of the sludge produced by their sewage treatment plants. The predominant digestion method used in North America to reduce sludge volumes is mesophilic anaerobic digestion, which produces Class B biosolids. Reuse of Class B biosolids often involves site restrictions because unlike Class A biosolids which are essentially pathogen-free Class B biosolids still contain significant pathogens.

The US Environmental Protection Agency has set standards (CFR-503) that designate Class A biosolids safe for unrestricted land application, including use as crop fertilizer, because of their negligible pathogen levels. These biosolids have been shown to increase crop yields, regulate nutrient release to the soil, and significantly reduce agricultural dependence on chemical fertilizers.

The debate on the safety of Class B biosolids is currently a hot topic in some states. While "biosolids-friendly" states such as Oregon and Washington have very successful Class B biosolids reuse programs, other states (California, for example) are seeing some counties place outright bans on all land application of Class B biosolids. These political pressures, coupled with the availability of cost-effective Class A technologies, have set the stage for the emergence of Class A processes as the dominant choice for future digestion projects. Many wastewater authorities evaluating treatment technologies for both greenfield projects and existing facilities requiring expansion are opting to treat sludge to Class A standards for ease of disposal and simplification of the recordkeeping requirements.

Demonstration Plant

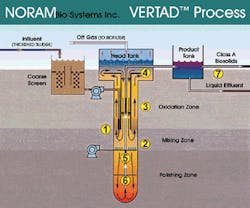

To meet long-term sludge management objectives, the King County (WA) Wastewater Treatment Division evaluated the VERTAD process as part of its "Technology Assessment Program." Developed by Noram Engineering and Constructors Ltd. of Vancouver, BC, VERTAD (Vertical Thermophilic Aerobic Digestion), is a auto-thermophilic aerobic digestion (ATAD) process. Unlike conventional ATAD processes, this technology employs a subsurface vertical reactor to aerobically digest wastewater treatment solids. Enhanced oxygen transfer in the process facilitates the production of Class A biosolids in a short solids retention time (SRT).

King County constructed a 5,000 population equivalent VERTAD facility at the East Section Reclamation Plant in Renton, WA. Operated by King County staff and evaluated by E&A Environmental Consultants Inc., the system was operational through a two-phase program during 1998 and 1999.

Results

- The vector attraction reduction and pathogen destruction requirements for Class A biosolids were achieved with a 4-day solids retention time. Lithium tracer studies confirmed strict adherence to time-temperature requirements.

- Oxygen transfer efficiency exceeded 50 percent.

- The product float thickened to 8-12 percent TS by a natural depressurization and CO2 release. Thickened product dewatered to greater than 30 percent cake solids with low polymer demand (14 lbs/ton).

- Organic nitrogen (Org-N) and fats, oils and grease (FOG) were preferentially degraded over organic solids comprised primarily of cellulose. Greater than 90 percent reduction in FOG was obtained.

- Odor panel testing indicated that off-gas from the process was generally odor-free. Off-gas character descriptors included terms such as "compost", "earthy", and "vegetation." The innocuous nature of the off-gas was attributed to the fact that compounds primarily responsible for the objectionable character of unstabilized wastewater solids (FOG and Org-N) were the most degraded fractions in the process.

- Capital and operating costs were low. A cost evaluation of full-scale implementation at King County treatment facilities indicated that a combined system with VERTAD and mesophilic anaerobic digestion was competitive with traditional anaerobic digestion.

Linking with Anaerobic Digestion

The process of dual digestion involves the use of an autothermal aerobic digestion process as a pretreatment step before mesophilic anaerobic digestion. King County's impetus to test combined digestion arose from its need, like many solids generators, to maximize solids destruction in order to minimize solids handling costs.

King County combined digestion studies indicate that mesophilic anaerobic digestion of the process can provide volatile solids destruction of up to 70 percent in a 15-day solids retention time (4-day SRT in VERTAD followed by an 11-day SRT in anaerobic digestion).

"VERTAD appears to have a synergy when linked in series with mesophilic anaerobic digestion. For example, while VERTAD readily degrades fats and proteins, anaerobic digestion is well-suited to cellulose destruction," said E&A project manager Larry Sasser.

Conclusion

During testing, the control digester experienced foaming and mixing difficulties whereas the dual digestion system had no associated problems. The ability to float thicken the VERTAD product allowed operation at higher solids concentrations in the anaerobic digester. The reduced flow associated with the thicker feed should allow for either reduced digester volume or increased solids retention time. Higher solids concentrations in anaerobic digestion should decrease the flow to dewatering equipment and would likely improve dewatering performance. As a side benefit, the thermophilic process provides hot water that can be used to heat anaerobic digesters.

Jeff Guild is an environmental and biological engineer at NORAM Engineering and Constructors in Vancouver.

Booth 1642