Urban Dewatering Challenges: Overcoming Noise, Odor and Space Constraints

By Michael Hodges

All dredging and dewatering projects require attention to detail to address the challenges inherent with processing thousands of cubic yards of material over a relatively short period of time. Bring these projects to an urban setting, and you introduce additional challenges to an already complex operation.

Community concerns over noise, odor issues and space limitations pose major obstacles for contractors working in and very near to neighborhoods and city centers. While the project owner must control the overall budget, he or she must also balance the overall project timeline, as communities can grow weary of a project site in their backyard.

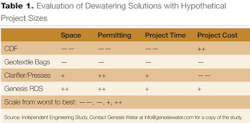

When evaluating the dewatering options for urban dredging projects against the concerns of space, permitting, and project time and cost, there are pros and cons to each solution.

A 2013 analysis by an independent international engineering firm looked at four dewatering solutions: Confined Disposal Facilities (CDFs), geotextile bags, a clarifier coupled with belt filter presses, and the Genesis Rapid Dewatering System (RDS) against these and other criteria. Each was evaluated utilizing three hypothetical project sizes (see Table 1).

CDFs will typically yield the lowest-cost dewatering option. The cost advantage, however, is quickly dulled by the space and project time requirements. Finding usable real estate for a CDF and convincing the community to dry a pond out over several years before the land is ultimately reusable may be a deal breaker.

In today's changing environmental landscape, obtaining a permit for a CDF in an urban setting may be next to impossible. While the cost advantage of CDFs is enticing, the other considerations may push this solution to the back burner and leave the engineer looking for another solution.

Geotextile bags may be a good fit for very small urban projects of 30,000 cubic yards (CY) or less, as space may be available to accommodate the smaller-dredge volumes. For these lower-volume projects, geotextile bags would require minimal site preparation and could provide a cost-competitive solution to mechanical dewatering that may require a higher mobilization and demobilization cost.

Permitting for a small geotextile project may also be achievable, as this solution is readily accepted by most permitting agencies. Once you gain more than 30,000 CY, the advantages of geotextile bags may diminish as space and overall project time become concerns by way of the bag layout becoming more complex and the time needed to dewater the dredge material lengthening. With larger projects, mechanical dewatering solutions merit stronger consideration.

Traditional clarifiers coupled with belt filter presses and the RDS are two mechanical dewatering solutions that can handle larger dredging and dewatering projects in an urban environment. Because both of these solutions can deliver dewatered cake and return clear discharge water in a timely fashion, permitting should be easier to achieve than CDFs or large geotextile bag solutions.

Both can operate on a smaller footprint than non-mechanical dewatering for larger projects, with clarifiers/belt filter presses requiring more space than the RDS. When evaluating project time, one must look at production throughput of these two solutions. Clarifiers/belt filter presses can be sized to handle higher dredge flows by increasing the number of belt filter presses to accommodate the desired solids output. Likewise, the RDS can be scaled to handle higher dredge flows by incorporating larger equipment or additional components.

The operational and maintenance (O&M) costs of operating multiple belt filter presses make this process the most expensive of all dewatering solutions. The resulting cake quality is very good, and it may close the project cost gap from other solutions for projects that require a long haul distance to the disposal facility.

The RDS throughput is quite high, as dewatered cake can be produced at a one-to-one ratio with the incoming dredge flow. This higher throughput coupled with low O&M costs makes the Genesis RDS an economical solution when compared to clarifier/belt filter presses and geotextile bags. Because no energy is applied and only passive dewatering occurs, the dewatered cake from the RDS will be wetter than the cake obtained from a belt filter press, although it still passes a paint filter test and can be immediately stacked or trucked offsite.

Urban dewatering projects pose additional challenges to an already complex operation. Space, permitting and project time and costs must be evaluated to find the best solution for the specific project. Just as no body of water is exactly alike, nor is the analysis of dewatering solutions in an urban environment.

About the Author: Michael Hodges is the founder and chief technology officer of Genesis Water. His pioneering work in clay chemistry and patented inventions have made him an authority on dewatering technology. He consults with colleagues worldwide on a variety of liquid and water projects and is a speaker at various national and international forums.

More WaterWorld Current Issue Articles

More WaterWorld Archives Issue Articles