Maintaining an Underground Potable Water Tank

Underground potable water tanks can be a cost-effective way to store healthy drinking water, but only if they are maintained properly. To reduce operating costs and conserve water, tanks must be inspected, cleaned, and maintained regularly. Documentation must be accurate, consistent, easy to analyze, current, and accessible to be a useful tool in deciding priorities and establishing a plan. Water quality and distribution monitored closely reduces the risk of contamination and water loss, and repairs made promptly will reduce property damage, liability, and possibly insurance.

Detecting and repairing leaks may be the most cost-effective way to conserve water in an underground water tank. Unnoticed leaks are costly occurrences in underground water tanks, and many may only be found when they become visible at the surface, or when a collapse occurs. However, leaks detected and repaired early may only incur minor costs.

Crack in concrete

The best way to make sure leaks do not go unnoticed is to get the tank inspected regularly and monitor the distribution carefully. If the system has experienced a noticeable drop in water pressure, a sudden occurrence with rust or air in the water supply, an unexplained sudden increase in water use, or water loss greater than 10%, then a leak may be suspected and priority attention is required. Structural damage can also cause leaks, and if the location of the underground tank has recently experienced an earthquake, then it should be inspected immediately to insure no structural damage or leaks have occurred.

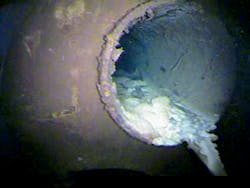

Sludge buildup

During the inspection, information and documentation needed to establish priorities should be gathered, and a full-bound written inspection report that includes a detailed evaluation, photographs, and recommendations of needed repairs, code updates, and a detailed cost estimate for each item should be included in the inspection. Signs of underground leaks should be noted, and inspectors should look for ponding water, discolored areas in the grass, cracks, and uneven structures. All aspects of the tank should be inspected for structural, safety, and coating conditions in accordance with NFPA, AWWA, OSHA, and EPA standards. The walls and floor are visually inspected for cracks or failures.

Roots growing into tank

Underground water tank inspections can also be performed with a robot, which eliminates the need to drain the tank and does not require lock out/tag out procedures or confined space permits, because no one enters the tank. However, to perform a robotic inspection the underground tank must be equipped with a manway at least 24 inches wide.

After an inspection has been performed and the condition of the tank has been determined, the issues found must then be addressed. Structural repairs and leaks are priority and should be repaired on an emergency basis. A tank with structural repairs could collapse under certain conditions and lives could be at risk, but structural damage is not the only risk associated with leaks.

Leaks can also result in water contamination. If water is leaking from an underground tank, then contaminated groundwater can also seep into the tank. Many water system operators realize the risks for contaminated water, but pathogenic microorganisms that create water-borne diseases are still sometimes found in public water systems. Pathogenic microorganisms are in human and animal feces, and they invade the body when water contaminated with them is consumed. An infection is often created by the bacteria, virus, fungi, or protozoa. These infections can spread rapidly, and sometimes even create an epidemic. Water is treated and tested for microorganisms during the water treatment process. But, if the clean and healthy water is stored in a contaminated water tank, then all the water becomes contaminated, and people’s lives may be put at risk.

Sludge buildup

Deaths and illnesses occur daily from unhealthy water, and water operators can lose their license to operate a water system if unhealthy water is found in their system. The best way to prevent the spread of infection and diseases linked to drinking water is to have these tanks inspected, cleaned, and disinfected regularly to prevent the growth of pathogenic microorganisms and other contaminants. Excess amounts of sedimentation can also cause sanitation problems. Cloudy or dirty water could indicate a sanitation problem and should be cleaned.

American Water Works Association (AWWA) states that, “Tanks should be washed out and inspected at least once every three years, and where water supplies have sediment problems, annual washouts are recommended” (AWWA M42-88). Cleaning underground tanks are much easier to perform now and do not require the system to be shut down or drained. Thanks to modern technology, underground water tanks can also be cleaned with robots.2015