CORROSION CONTROL: Polyurethane System Helps Combat Corrosion

By Sarah Timleck

The water and wastewater industry requires a corrosion protection system that is able to withstand the corrosive environment often experienced by municipal infrastructure. One such coating is 100 percent solids rigid polyurethane, which has excellent chemical, impact and abrasion resistance, adhesion, and is resistant to cathodic disbondment and undercutting.

In choosing a corrosion protection system, one must remember that not all polyurethanes are created equally. An understanding of the difference between rigid and elastomeric polyurethanes is essential to any discussion of polyurethane technology. 100 percent solids polyurethane chemistry is based on the reaction between an isocyanate and a polyol. Rigid and elastomeric polyurethanes are differentiated by the degree of cross-linking of polymeric molecules in the coating's formulation.

The chemical bonds of rigid polyurethane systems are highly cross-linked to each other to create a hard, dense protective membrane that has excellent chemical and corrosion resistance. Elastomeric polyurethane systems have a more linear chemical structure with much less cross-linking, creating a stretchy and elastic quality. While elastomeric polyurethanes tend to have good impact strength and flexibility, in most cases they offer poor tensile adhesion and cathodic disbondment.

There is a wide range of polyurethane coatings in the marketplace, ranging from the rigid and elastomeric systems mentioned above to foams and "polyurethane paints" sold at the consumer level. By setting out tough performance requirements which only the best corrosion protection systems are capable of meeting, standards help engineers separate out the systems that are suitable for corrosion protection of water and wastewater structures.

An example is the newly released ANSI/AWWA C222 Polyurethane Coatings for the Interior and Exterior of Steel Water Pipe and Fittings. C222 requires minimum adhesion of the coating to the steel of 1500 psi whereas C210 (liquid epoxy) requires only 400 psi. The standards-creation process helps original equipment manufacturers and end users raise their coating performance requirements and dramatically increase the overall expected lifespan of the infrastructure.

New Developments

Recently there have been some exciting developments in the world of polyurethane research. One innovation involves the development of a polyurethane protective lining that incorporates an anti-microbial fortification.

Microbiologically Influenced Corrosion (MIC) can present a severe problem to the interior of wastewater pipelines. Sewage is a rich source of nutrients for sulfate reducing bacteria and enables the generation of enormous bacteria colonies.

The first step of MIC is the fermentation of raw sewage, which generates methane and hydrogen sulfide gases. These gases, in combination with carbon dioxide and water vapors, produce a mildly acidic environment. These conditions are ideal for the reproduction of microorganisms (primarily thiobacilli) which further oxidize the hydrogen sulfide gas and other sulfur-containing materials in the wastewater. Secreting sulfuric acid as waste, these microorganisms reduce the wastewater pH and create an extremely acidic environment, resulting in the rapid corrosion of the pipeline.

100 percent solids rigid polyurethane coatings have been used for years to protect wastewater structures by providing a membrane or barrier between the structure and its corrosive environment.

Polyurethane protective linings that incorporate an anti-microbial fortification take this protective process one step further. On contact with a microorganism, the lining works by disrupting (or rupturing) the cell membrane, interrupting the normal life process of the cell and effectively destroying it. Anti-microbial fortification is difficult to achieve; the effectiveness of the anti-microbial fortification is directly linked to the way in which the anti-microbial agent is incorporated into the coating. Anti-microbial agents which have been properly incorporated into the coating should not lose their anti-microbial activity over time. In theory, they should last forever.

While 100 percent solids rigid polyurethanes feature superior abrasion resistance, applications involving extremely high flow rates and unusually abrasive instances demand something more. Newly developed Ceramic Modified coatings are engineered to meet the challenge of highly abrasive or high flow applications, offering durability, weatherability, corrosion and chemical resistance.

Case Histories

Rigid polyurethanes offer a wide range of applications for the water and wastewater markets. For over 25 years Madison Chemical Industries has been manufacturing 100 percent solids polyurethane coatings and linings which have been used for a variety of applications involving both potable water and wastewater. The following are a few examples:

111 Years Of Design Life

In 1991 the City of San Diego embarked on Phase One of the Fiesta Island Replacement Project. The project involved six miles of ductile iron pipe protected from corrosion by 25 mils (625 microns) of Madison's 100 percent solids rigid polyurethane coating. Sacrificial magnesium anodes also were used to protect the 12 inch diameter pipeline from corrosion. Two years later, DeC Consultants Inc. tested the pipeline's corrosion protection system.

DeC's analysis showed the coating system to have an installed efficiency of 99.66 percent and the pipe an actual current requirement for corrosion protection three times less than the design value. The report went on to state that, given the condition of the polyurethane coating and the corresponding low anode consumption rate, the system had a projected design life of 111 years.

District Combats Corrosion

Hampton Roads Sanitation District (HRSD), headquartered in Virginia Beach, VA, was among the first utilities in North America to use Madison's 100 percent solids rigid polyurethane coatings to protect pipe internals against aggressive sewage and microbiologically influenced corrosion (MIC).

In its initial evaluation of the product, HRSD made a standard two inch tap into the side of a three foot long piece of ductile pipe lined with the polyurethane coating. The pipe was then suspended into a manhole known for its extremely corrosive conditions. After 6 months the pipe was removed and the coating inspected. While there was some minor corrosion right at the saw cut, there was very little evidence of undercutting or loss of adhesion around the unrepaired area. Based on these results, HRSD has gone on to specify rigid polyurethane coatings wherever they anticipate aggressive sewage conditions.

Currently HRSD is using the company's coatings and linings for the Lake Ridge Interceptor Force Main, which runs from HRSD's Atlantic Wastewater Treatment Plant, servicing Virginia Beach and Chesapeake. HRSD knows conditions within the sewer line will be extremely aggressive.

HRSD and their design engineers, Buck, Siefert, & Jost, chose to line 10,000 feet of spiral welded steel pipe with 20 mils of Madison's Corropipe II WasteLiner®, which is designed to handle extreme conditions, such as when pH levels fall below 1.

About the Author: Sarah Timleck is responsible for Marketing Communications at Madison Chemical Industries. For further information on 100 percent solids polyurethane coatings and linings, you can reach Sarah at 905-878-8863 or email [email protected].

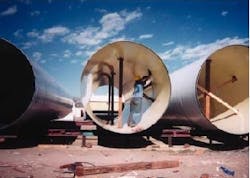

Some 8,000 linear feet of 108 inch diameter steel pipe was lined with Madison's CorroPipe II PW(r), a two component, rapid setting, 100% solids rigid polyurethane, for the Denver Water Marston Reservoir project.