Meeting Flow Monitoring Needs In CSO and Stormwater Systems

By Terrance L. Burch

Municipal water and sewerage authorities are facing new and increasing needs for accurate flowrate monitoring within their wastewater and stormwater conveyance systems and treatment facilities. Federal and state environmental regulations concerning the discharge of pollutants from urban wastewater collection systems and treatment facilities have become much more stringent in terms of requiring adequate treatment of collected wastewater and stormwater runoff before it is discharged back into natural receiving waters. This has driven the requirements for continuous, high-accuracy flow measurement and monitoring at key junctures in wastewater and combined wastewater/stormwater collection systems, for influent and effluent lines, and for treatment process measurement control and verification.

In addition, cost-allocation billings to the communities that contribute flowage into municipal systems have generally changed over, from the earlier years of prorated population-based cost assessments, to billings based on actual volumetric flow sent into collection systems by the tributary communities. All of these considerations have resulted in a wide array of flow measurement applications that have been addressed using multiple-path ultrasonic transit-time flowmeter systems. This article describes the importance of accurate flow measurement technology in combined sewer overflow (CSO) applications and stormwater runoffs, the federal requirements for flow measurement, and flowmeter system implementations that have helped municipal authorities meet these requirements.

Flowmeter System Requirements

The Environmental Protection Agency (EPA) has established the National Pollutant Discharge Elimination System (NPDES) as a permitting program to control water pollution by regulating point sources. Point sources are those that discharge pollutants into waters and they include, among others, stormwater, CSOs, and sanitary sewer overflows (SSOs). This program is designed to attain minimum water quality standards in the receiving waters affected by wet-weather discharges. The EPA stormwater and CSO policies have been integrated with NPDES permitting to require the use of Best Management Practice (BMP) control strategies and discharge monitoring programs to demonstrate compliance.

This regulatory focus increases the need for highly accurate flow monitoring systems to be deployed at a variety of locations within combined stormwater and wastewater collection networks. Flow monitoring data from key locations over a range of wet-weather conditions can deliver more accurate data than computer models. This increased data accuracy can also highlight specific collection system features (e.g., greater than expected flowrates or water levels with respect to design capacity) requiring analysis for appropriate BMP implementation.

Flowmeters for stormwater and CSO monitoring are typically required to operate under both free-flowing (i.e., in partially filled conduits or open channels) and surcharged (pressurized) conditions. Since flow velocity profiles in surcharged conduits are significantly different than under free-flow conditions, a “compound” approach that automatically selects an appropriate integration method for computing representative velocity profiles and resultant averages will provide better continuous flowrate accuracy.

Ultrasonic transit-time flowmeters can be effectively utilized to meet specific site monitoring and documentation required for NPDES permitting by providing highly accurate and continuous flowrate measurement during dry- and wet-weather conditions. Transit-time flowmeters include bi-directional (reverse flow) measurement capability and can be configured for multiple acoustic paths, making them extremely accurate over a wide range of changing water level and flow conditions, as well as in locations where other measurement methods cannot reliably function.

The multiple-path transit-time method can provide accurate flowrate measurement even at sites where flow profiles are not well developed and may be significantly distorted by upstream flow perturbations. The use of acoustic paths positioned at multiple elevations across the pipe or channel also provides an ideal means to accommodate flowrate measurement under wide ranging water levels. Flowrate measurement accuracy improves under full-pipe (surcharged) flow conditions, since water level measurement is no longer a factor in the overall measurement uncertainty.

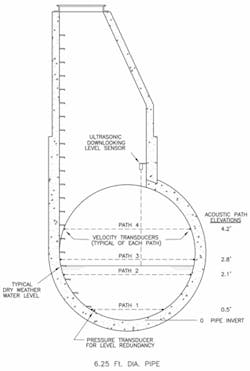

Figure 1. Typical manhole site multiple-path flowmeter configuration.

Conduit sections that are well removed from upstream bends, obstructions, or other flow disturbances will exhibit “fully developed” flow velocity profiles, and a “co-planar” arrangement of parallel acoustic paths is utilized, with acoustic paths placed at three or four selected elevations across the flow conduit (see Figure 1). In cases where upstream flow disturbances are present and within 10 diameters of the metering section, the use of symmetrically crossed acoustic paths at each path elevation can maintain nominal flowrate measurement accuracy. This is a significant capability that provides the flexibility to achieve high-accuracy flow monitoring at locations where disturbed flow profiles or off-axis velocity components may be present.

Ultrasonic Transit-Time Flow Measurement Principles

Accuracy in measuring flow velocity requires knowledge of the acoustic path length and the angle the path makes with respect to the meter centerline. Typically, transit-time transducers are permanently installed and the meter is “dry” calibrated. Calibration is based on careful measurements of the as-built path lengths, path angles, and path elevations taken at the time of transducer installation. Since these values do not change, transit-time meters do not require any periodic recalibration over time.

In the multiple-parallel-path method, average velocity is measured nearly simultaneously at more than one elevation in the flow. These simultaneous velocities define a velocity profile throughout the flow cross-section for use in calculating an integrated flowrate. The measurement of average velocity at multiple elevations across the flow also makes the method responsive to changing flow profiles associated with quickly changing CSO flow regimes, which can go from dry to surcharged within minutes during a rain event.

Numerous independent field and laboratory tests have shown that accuracies of ± 0.5% to 1.0% of actual flowrate can be achieved in surcharged conduits with a 4-path configuration. Under free-flowing (non-surcharged) conditions, flowrate accuracy within ± 2% to 3% of actual is achieved with a 3-path system when all acoustic paths are submerged.

Typically the lowest acoustic path is placed at an elevation of ~6 inches to ensure that velocity data becomes available early in a rain event. A typical configuration utilized in stormwater or combined sewerage pipes at manhole locations is shown in Figure 1.

As noted in the previous section, flowrate accuracies can be maintained even at sites with poor hydraulic conditions by adding a second plane of transducers in a crossed-path configuration. The crossed-path approach compensates for any errors due to cross-flow (non-axial flow components) through the measurement section caused by upstream disturbances.

Flowmeter Applications

Billing and Cost-AllocationA northeastern municipal sewerage authority maintains 17 meter chamber sites throughout the multi-community combined wastewater collection network with contributory inflow from the member communities carried to a central wastewater treatment plant (WWTP). Previously, the meter chambers had been equipped with Parshall flumes for gauging the flowrate contributions from the member-community’s connections to the main interceptors influent to the WWTP. High flow conditions during wet weather periods were causing surcharging throughout most of the collection system. This often resulted in backwatering and flume submersion at the metering chambers. The frequent loss of functional flowrate measurements under wet-weather conditions was hindering the fair and equitable allocation of treatment costs among the tributary members.

After a thorough evaluation and competitive demonstration project, the Accusonic Model 7510 Flowmeter systems were selected. These were installed at the meter chambers to work in concert with the existing flume-based measurements. The flowmeter system components conformed to applicable National Electrical Code Class I, Division 1, Group D Hazardous Explosive Atmosphere requirements. NEMA 4X equipment enclosures were installed on post mounts on the roof of each existing flume meter chamber to securely house the system’s electronic components and ensure that they would remain unsubmerged during the large flooding events that had been documented by high-water marks on most of the metering chamber walls. Voice-grade telephone line service was implemented at each site for automatic transmission of all collected data to the WWTP facility. A back-up power source comprising batteries, charger, and DC-AC inverter was installed in a separate NEMA 4X enclosure for supporting the flow monitoring system during temporary AC mains power outages.

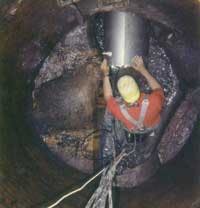

Flowmeter transducers were premounted on stainless steel sheet-metal sleeves and installed via manhole access adjacent to the meter chambers. Installations were accomplished during early morning conditions when flow was about 12 inches deep during the installation activities, which required approximately 3 hours of in situ work for installing and securing the pipe insert sleeve and performing a final alignment of the transducers. The 3-path transducer configurations provided high-accuracy flow monitoring capability throughout the entire range of dry-to-wet weather flow conditions. Figures 2 and 3 show the pipe sleeve insert and installation activities.

Pipe sleeve insert.

Multiple-path transit-time flowmeters were located at all 17 flow monitoring sites, working in conjunction with the centralized, automated, computer data collection and archiving system. The complete flow monitoring network was installed and operational by the end of December 1997. These flowmeters have been providing the sewerage authority with reliable, high-quality flow data via the computerized network ever since. The data and information they provide are utilized for objective and equitable cost allocations based on true influent flow contributions to the collection and treatment network.

CSO Treatment Facility Activation

The City of Saginaw, Michigan, installed Accusonic multiple-path transit-time flowmeters during the period 1995-1999. These meters have been very useful in understanding the collection system hydraulics during rain events that activate the CSO basins. For example, one CSO facility receives flow through three separate influent lines. Two of these are gravity lines, and the third is from a pump station that feeds into the facility’s vortex separator. Accusonic flowmeters are installed on the two gravity lines, while pump rate curves are used to determine flow into the vortex separator. A transit-time flowmeter was not used on this line due to air entrainment caused by flow through the separator.

Readings from the transit-time flowmeter in one of the gravity lines would sometimes indicate a reverse-flow condition when the pump station was activated. What was initially considered a flowmeter error was actually indicating a condition where pumped flow increased the hydraulic grade line at the inlet of the basin. This caused the gravity line to flow backwards or upstream into the gravity sewer. Flow in the gravity line would reverse once pumping stopped. This type of backflow condition is very difficult for system modelers to predict and quantify without real-time, reliable flow data.

About the Author:

Terry Burch is Marketing and International Sales Manager at Accusonic Technologies, a Division of ADS LLC. He is responsible for working with engineering, marketing, and customer groups in the application and development of flowmeter systems and services that can best meet municipal water and wastewater requirements for solving problems through application of state-of-the-art flowmeter technology. Burch has a broad background in technology R&D, marketing, project management, engineering, and customer liaison. He may be contacted at [email protected].