System Uses Internet to Monitor Water Well Pump Controls

There are few absolutes in life, but one thing every plant operations manager can count on is the expectation of finding ways to do a little more every year with the same resources. In water and wastewater processing, one of the biggest boons to productivity over the past 15 years has been the advent of cost-effective ultrasonic level measurement controls which allow plant managers to automate pump operations with little need for ongoing maintenance or intervention.

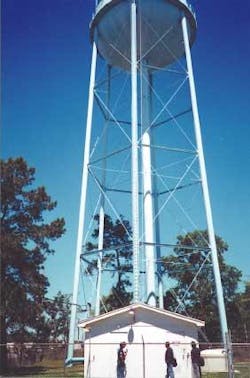

The newest advance in ultrasonics is the combination of level control gear with the latest communications technology. In Lumberton, TX, municipal utility workers are using the Internet to access real-time data from the pump controller at Benny Water Well No. 1, one of the Lumberton Municipal Utility District's three groundwater well operations.

Using a standard Web browser like Microsoft Internet Explorer or Netscape Navigator, workers can check more than two dozen variables, including levels in both elevated and ground storage tanks, as well as faults, start times, and aggregate run times for any of the three pumps at the site.

The control and communications setup at the well is made possible by the multiple capabilities of the Milltronics' EnviroRanger ERS 500, which not only controls pump functions but also has various PLC capabilities, an integrated telemetry unit and full data logging capabilities.

The Web-based communications are provided by Milltronics for a monthly service fee. Data from the device is transmitted via a satellite communications link and accessed via a password-protected Web site. The setup allows on-call personnel to receive emergency alerts via fax, pager or phone should any problem arise. It also allows workers to troubleshoot problems via the Web before driving to the well site, which is about three miles from the utility's headquarters, said Robb Starr, Operations Manager at Lumberton.

Starr recalled a day recently when a service technician went to the well site to do regular maintenance on some water treatment gear.

"They turned off the pumps to begin doing their work, and I got a message on my pager alerting me that the pumps had been switched off," said Starr. "I knew exactly when they started work. It's like having somebody standing there watching the well all the time."

Lumberton is a community of 18,000 about seven miles north of Beaumont in southeast Texas. Lumberton Municipal Utility District serves a 63-square-mile area. The district operates both water and wastewater processing operations, and has three groundwater wells.

Benny Water Well No. 1 supplies about 750,000 gallons per day. A pump lifts groundwater from the well depth of 800 feet into a 300,000-gallon ground storage tank. Water is treated with chemicals, including phosphate, chlorine, and fluoride as it is pumped into the ground storage tank. Booster pumps lift water from the ground storage tanks to a 250,000-gallon elevated storage tank. From there gravity carries the water to customers' homes and businesses.

In 1999, the pressure switches that measured water levels at the well failed. The switches, mounted inside at the bottom of the tanks, measured the weight of water in the tank in pounds per square inch. Inputs fed data from the switches to a controller that activated pumps based on high and low ettings within the tanks. Over time, the switches became corroded, fatigued, and gradually became less effective.

Ultrasonics were the logical choice to upgrade the level control system at the well because they are stable and cost-effective, Starr said. The ultrasonic system consists of two primary elements, a transducer that emits and receives high-frequency sonic pulses, and a controller that interprets the return echoes, calculating level and volume.

Ultrasonics had been used extensively in Lumberton operations for years, including an application involving the ERS 500 at the district's main wastewater lift station, where the controller runs five pumps moving more than 1.5 million gallons of wastewater per day.

The dual-point ERS 500 was well-suited for Benny Water Well No. 1 because a single unit could control pumps and transducers on both the ground and elevated storage tanks. This led to an overall savings in control equipment because it eliminated the need for separate controllers on the two tanks, Starr said.

Moreover, ultrasonics provided a degree of control that manual technology like pressure switches simply couldn't match. For instance, the finest adjustment on the old pressure switches allowed for a variation of as much as one and a half feet. With ultrasonics, the ERS 500 can specify high and low levels to 100th of an inch.

The EnviroRanger also allowed the district to save money on its electric costs by lowering peak power demand at the well. It is most efficient to stagger the start times of each booster pump to lower the peak demand. By programming the unit to stagger the start times for the pumps, peak demand at the well was significantly lowered.

Starr initially accessed the communications features in the EnviroRanger via a dial-up modem, leasing a dedicated phone line to the well specifically for that purpose. The line and modem were discontinued in favor of the Internet service in late 2000 because the monthly cost was less, and the Internet link allowed workers to access information round-the-clock, without having to dial up the modem, Starr said.

The ultrasonic setup at the well cost approximately $3,300, including the ERS 500 controller and both transducers.

"I don't know of another product that will log and hold this much information," said Starr. "The only other way to do this would be to put in a PLC and get it integrated with other equipment like a data logging system and a communications system. By the time you paid for the integration it would probably cost at least $20,000."

The ERS 500 has proven so effective, Starr is preparing to install similar systems at the district's other two water wells.