Click here to enlarge imageFor the last several decades, on-site generation of chlorine from a variety of manufacturers has eliminated the safety concerns of concentrated, bulk chemicals. As time has progressed, both the process of on-site generation and the available equipment have been refined and improved, prompting more customers to turn to on-site generation for their disinfection solution. Existing installations number at least 4,000 units.

All on-site generator manufacturers electrolyze a brine solution to generate a chlorine-based disinfectant. On-site generators can be designed to produce either hypochlorite or mixed-oxidant, a chlorine-based disinfectant with stronger oxidizing properties. Both systems use the same feedstocks of salt, water, and power, and the U.S. Environmental Protection Agency (EPA) accepts on-site generated oxidants as a compliance technology for disinfection of drinking water.

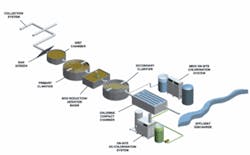

On-site generation of chlorine was introduced as a commercial technology several decades ago. Installations can be found more commonly in potable water applications, but the technology is also used in wastewater, cooling towers, swimming pools, and industrial process water. In a wastewater application, common salt is stored in a brine generator and fed to the on-site generator. Electrolysis inside the cell converts the brine solution to a chlorine-based disinfectant. This disinfectant is then stored in a solution tank and injected into the chlorine contact chamber at the appropriate dosage. Advantages include not only the elimination of hazardous chemicals, but also the ability to avoid degradation of the solution, improved bacterial inactivation rates, and reduced usage of dechlorination chemicals.

Design Improvements

Miox’s new product release will focus on mid-size generators, ranging in capacity from 25 pounds of free available chlorine per day up to 200 pounds per day. These systems are modular and can be coupled together for even more capacity and redundancy.

With the new cell design, a customer will be able to expand capacity within the same enclosure. No other components or adjustments will be needed other than a modification to the modular electrolytic cell. This feature is beneficial for growing communities or for changing water quality that may require additional treatment.

Redundancy can be achieved with multiple cells, each having its own dedicated brine pump, power supply, and controller, so that any single unit can be taken off line for maintenance without impacting performance of the other units.

Switching Disinfectants

The new system will also allow switching between hypochlorite and a mixed-oxidant disinfectant with simple changes to the system. This feature offers the ability to test the benefits of mixed oxidants on a particular water supply, or to expand chlorine capacity in the same size footprint.

The new system also offers an improved cell design that translates to a longer cell life and less susceptibility to contaminants.

The materials of construction will be rotomolded plastic with a lightweight structural frame, eliminating the corrosion issues common with stainless steel. The new system will still be fully enclosed in a cabinet, providing protection from environmental damage or excessive humidity, and containing the components within an enclosure as an extra measure of safety.

Front and rear removable panels provide access to all system components, with modular sub-systems that can be removed for even easier maintenance. A window at the top of the cabinet will improve visibility by allowing extra light. Access to plumbing will be directly from the back of the cabinet, allowing for a cleaner installation and total separation of electronics and hydraulics. The floor of the cell cabinet also contains a tilted tray to improve drainage and prevent any issues that could result from cell leakage.

The new systems will use air-cooled power supplies, per customer feedback stating general preference for this design. A unique feature of the Miox system will be the ability of the air cooling to provide the air flow source for the optional dilution air hydrogen vent. Finally, the new systems will offer several different control schemes, per customer preferences.

Miox’s new design will be available for shipment in early 2007.