Pinpointing Hard-to-find Leaks in Manilla

Maynilad Water Services is the water/wastewater services provider for the West Zone of the Greater Metro Manila Area of the Philippines. Facing pressure issues due to leakage, it was not feasible to spend over US$40 million to recover 5,000 m3/day. Instead, using hydraulic modelling, the utility was able to identify and repair the leak for a fraction of the cost.

By Perrine Parrod

The Tinajeros pipe network, operated by Maynilad Water Services in the Philippines, is relatively old, particularly its asbestos cement pipe feeder line which was laid in 1984.

As a result, this district metered area (DMA) had long been tagged as a problem area: although it had two inflows with high pressure, potable water could still not be supplied to customers within the prescribed service level.

The pipe network experienced high head loss which made it impossible to achieve the minimum service level of five metres of pressure throughout the day. Total pipe replacement, a five-month project estimated at US$41.7 million, was unfeasible.

Increasing the pressure from the supply source was one way to address the service level problem. However, because of high losses in the pipe system, increasing the pressure would also increase non-revenue water (NRW). Maynilad also tried to split the DMA into two pressure zones by locating the balancing points, which did not significantly contribute to the improvement of service levels.

Leak detection was conducted and hundreds of service pipe leaks were reported, however, their repair did not contribute to the improvement of pressure in the area. Moreover, years of roadway upgrades meant that the pipes were also buried under two metresof concrete pavement. This made it particularly ineffective to detect water leaks using sounding equipment, due to the existence of drainage lines parallel to the pipe network. These challenges pushed Maynilad to look for other, more innovative solutions.

Maynilad considered total pipe replacement to solve the issue. However, time and budgetary constraints from design through to construction made this alternative not feasible. The initial cost for total pipe replacement of over US$1.7 million could not be justified for only 5,000 m3/day of recoverable NRW.

The utility then started gathering data and conducting field analysis. Pressure profiling was done to determine where the pressure drop occurred. Spot pressures were gathered from the source up to the extreme portion. However, this study did not yield any significant results because the pressure started to drop just 30 metres from the source and then continuously dropped as it reached the other end of that network section.

Finding the optimal solution

The last solution was to build a hydraulic model of the DMA and calibrate it according to the existing condition of the network. Supply and pressure management made through the calibrated hydraulic model was useful in the discovery of leakage in the system.

Maynilad used Bentley's WaterGEMS software for the analysis and design of water distribution systems. Compared to conducting repeated test pits or excavations to check whether a leak detected through sounding was actually occurring, the use of hydraulic modeling significantly narrowed down field investigation.

A leak was pinpointed in the location indicated by the model. Upon excavation, it was discovered that an entire six-linear-meter section of the 200 mm asbestos cement pipe was busted longitudinally, causing the huge pressure drop in the area.

Network improvements

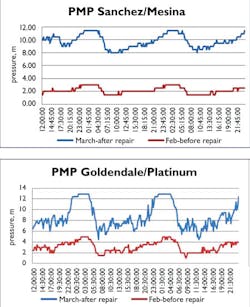

The leak repair contributed an increase in pressure by 6 metres (8.6 psi) and billed volume by 200 m3/day (0.2 MLD). It also reduced NRW by almost 1,900 m3. Leak repair only took two days and cost US$1,160 – an amount equivalent to less than 1% of total pipe replacement.

In comparison, total pipe replacement would have required five months from design to implementation, incurring higher design and construction costs.

Perrine Parrod is from Bentley Systems. This article can be found online at www.wwinternational.com

***************

Return on Investment

- Leak repair cost only USD$1,160 – an amount equivalent to less than 1% of total pipe replacement, which was originally considered..

More Water & WasteWater International Archives Issue Articles