Kristal membranes have long been a key membrane technology for Hyflux, be it in the mega-sized water plants delivered by the company, or the smaller projects that Hyflux's various customers supply. Kristal membranes are used in water treatment-based applications such as desalination, wastewater recycling and recovery and surface and groundwater purification. It is an excellent barrier for the removal of suspended solids and microorganisms and for the reduction of organic and colloidal matter. This ensures high quality permeate which protects RO membranes and and minimizes the cost of operating them. .

The new tri-bore membranes have increased overall diameters of 1.95mm and 2.20mm for the Kristal 600ET3 and Kristal 2000T3 respectively (a 40 - 45% increase from previous Kristal membranes) while the diameter for each of the bores is 0.6mm. The increase in the overall hollow fibre thickness leads to even better membrane durability and tensile load-bearing ability. This means that fibre breakage may very well be a thing of the past. In fact, to this day, no fibre breakage has been observed even after months of rigorous testing in actual operating plants.

The tri-bore membrane combines the "best of both worlds" – it avoids the common challenges posed by most multi-bore configurations by having the inner bores side-by-side, as tri-bore membranes have no bores being surrounded by other bores. "Dead flow" areas are thus almost non-existent.

On top of that, one tri-bore membrane fibre gets the combined strength of three individual hollow fibres, so it combines both superior tensile strength and good permeate flow rates.

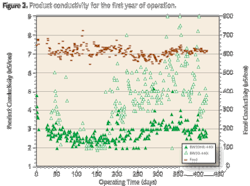

The hallmark of the Kristal membrane is consistently good permeate quality. The Kristal 600ET3 and Kristal 2000T3 tri-bore membranes carry on this tradition. Unlike certain conventional treatment methods, the Kristal® membranes promise constantly low permeate turbidity and SDI that remain unaffected even by large fluctuations in the feed water quality.

Therefore, users can rest assured that even if a previous process fails, the resultant permeate from the Kristal membrane will still be fit to be used as feed water downstream processes or for potable water consumption.

The main material of the Kristal 600ET3 membrane is polyethersulfone (PES) – a polymer that is inherently hydrophilic with good chemical and pH resistance, much like its K600 predecessors. The PES membrane is then modified to augment its hydrophilicity and chemical resistance to enhance the membrane's filtration performance.