By Joo Nian Ng

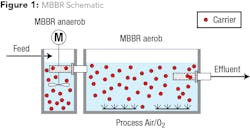

As a biological wastewater treatment solution provider specializing in moving bed biofilm reactor (MBBR) technology, we find it is sometimes necessary to explain thoroughly to our clients what MBBR is and how the MBBR process works. Clients frequently ask us how much carrier media they need and, as a result, we’ve developed a reliable way to calculate the amount of carrier media required by our clients.

General Rule for Calculation

The basic and most accurate way to determine the required amount of MBBR carrier media in a wastewater treatment application depends on the organic load that needs to be removed, which is directly influenced by the flow rate, influent and effluent concentrations.

Organic Load = Flow Rate x (Influent Concentration – Effluent Concentration)

Once the organic load to be removed is known, the required carrier media quantity can be calculated. Different types of carrier media have their own different removal rate or efficiency. Yet, this removal efficiency is strongly dependent on the application and water temperature.

For a serious calculation, these factors must be taken into consideration first before deciding on the removal efficiency of a carrier media. After all, it is the bacteria that grows on the carrier media that actually treats the wastewater, not the carrier media itself. Because bacteria is a living organism, its activeness is influenced by the surrounding conditions and the substances it will degrade. To draw an example: Who would prefer to eat ice cream during cold weather?

Once the removal efficiency is determined, we can calculate the carrier media requirement for a certain wastewater application:

Carrier Amount = Organic Load / Removal Efficiency

Story: Tom and His 11 Trained Workers

Tom owns a production factory. Every day, the factory produces 10 kg of a certain product. Based on his experience, Tom knows that, on average, one trained worker with correct tools could manage to pack and ship out 1 kg of the product daily. Being a predictive man, Tom considers the probability that one worker might get sick. To be on the safe side, he has 11trained workers instead of 10. This helps him prevent an overcapacity situation in the warehouse in the event that one of them is sick or the factory has to increase its production capacity. With his 11 trained workers and correct tools, Tom’s factory operates smoothly every day without trouble.

Now, let’s compare this with the biological wastewater treatment process. The product is the organic load to be removed by means of wastewater treatment; the trained workers and tools are equivalent to the carrier media and biomass in the wastewater treatment process, respectively. Similar to the workers who cannot pack and ship out the products without tools, the carrier media cannot remove the organic load from the wastewater without biomass.

If one day Tom’s factory starts producing another product that requires a different packing method, he doesn’t dismiss his 11 workers and hire a new group. Rather, he allows his workers time to become familiar with their new working tools. The same applies to biological wastewater treatment: The biomass that grows on the carrier media will gradually adapt itself to remove a different type of organic load or concentration.

Characteristics of a Good Carrier Media

In order for Tom to ensure his factory can run smoothly, he needs both skilled workers and a good set of tools for them to use. The lack of either will slow down the packing speed. For biological wastewater treatment with MBBR, the biomass as well as the carrier media that acts as the housing for the bacteria are very important.

A good MBBR carrier media provides more than just a protected habitat for the bacteria to grow; it also ensures that all bacteria that grow on it are sufficiently supplied with nutrients for their metabolism. During the biological treatment process, the bacteria consume dissolved organic substances. Without sufficient nutrients, the growth of the bacteria is hindered, or worse, the bacteria die off. These phenomena will reduce the removal efficiency and lead to an unqualified wastewater discharge. Hence, a proper selection of the carrier media is essential. This decision will affect both the organic removal performance and the cost required to run the plant.

A good MBBR carrier has the following characteristics:

• A large protected surface area to maximize the amount of biomass;

• A porous surface to strengthen the biomass’s adhesion;

• An optimal substrate diffusion depth to ensure the metabolism;

• Wear-resistance for durability.

In terms of treatment, a good MBBR carrier media ensures that all biomass is active to remove the organic substances from the water. From the user’s perspective, a good MBBR carrier media eases the operation and provides a variety of savings, such as in construction and operation.

Summary

In a wastewater treatment application, the required amount of MBBR carrier media depends on the organic load that needs to be removed by means of the bacteria’s metabolism, the rate of which is influenced by water temperature and the type of substrate.

Although MBBR carrier media might just be a little piece of plastic (or some other material), its role in wastewater treatment is vital to keep the biomass active in order to deliver the best possible organic removal performance. WW

About the Author: Mr. Joo Nian Ng, M.Sc., is a sales engineer with Multi Umwelttechnologie AG, a company with over 20 years of experience in the application of biofilm media in the treatment of wastewater. To learn more, visit www.mutag.de/en/startpage.