Recycling and reuse of water have been in practice since shortly after the earth was formed, using natural methods, cycles, and filters. In recent decades, technology has been incorporated to speed up the natural processes in order to meet the ever-increasing demand for clean water. Natural processes in water reclamation are now typically employed in combination with above ground-engineered processes.

Reusing water results in savings, of both resources and costs, according to the Environmental Protection Agency, which regulates many aspects of wastewater treatment and drinking water quality.

Utilities see the benefit in reuse as a backup for drought, sustainability, and resiliency. Considering that water is a finite resource, it is imperative to recycle the water we have to the appropriate standard for the application.

Reuse for nonpotable applications has long been accepted and is a successful means to maintain freshwater supplies. But in some jurisdictions, it isn’t enough. The need to augment water supplies with reuse of used water for potable water applications is growing. And regulations are being developed. Existing technology can treat and reuse water safely. Little by little, it is becoming more accepted by the public.

Indirect potable reuse (IPR) has been accepted since 1978 and regulated by Title 22, says Christina Alito, water process engineer for HDR Engineering, an energy consulting company. Groundwater regulations adopted in 2014 focus on direct injection and the most stringent treatment requirements for IPR, in which pathogens and organics are removed. Virginia is currently using IPR for groundwater irrigation.

Gaining recognition is direct potable reuse (DPR), which requires recycled water to be processed to drinking water standards. Utilities are still pilot testing DPR for groundwater replenishment and surface water to serve communities, Alito indicates.

In the past, water reuse was driven by scarcity, particularly in the west, but now Alito says it’s being driven by sustainability. “There’s been a shift. It was driven by drought, but that’s changing.” Still, the situation fluctuates wildly from one region to another. “Some states use direct potable reuse, some have no regulations at all.” Despite the sporadic implementation of regulations, the EPA indicates that no documented cases of human health problems due to contact with recycled water treated to drinking water levels have been reported.

Regulated or not, water reuse has been expanding rapidly. However, the type of reuse varies across the country, depending on the issue at hand and the resources available. Recycled water for some uses, such as landscape irrigation, requires less treatment than for potable use. Because of this increasing usage, most states are beginning to establish—if they haven’t already—criteria for the use of recycled water for various applications.

Most commonly used for nonpotable purposes—particularly irrigation of landscapes, agriculture, parks, and golf courses, but also for industrial processes in paper mills, construction, and cooling towers—recycled water projects are on the rise. They include recharging groundwater aquifers and replenishing surface water reservoirs and can be completed by injecting or spreading recycled water into groundwater aquifers to supplement supplies and prevent saltwater intrusion in coastal regions. The Water Factory 21 Direct Injection Project in Orange County, CA, began injecting highly treated recycled water into the aquifer to prevent saltwater intrusion in 1976.

California is further ahead, particularly with indirect potable reuse, Alito states. “California has been using membranes and reverse osmosis, but that’s changing.” The momentum is driven by regulations in California and Texas, and she sees it moving to the east coast. “Virginia is now using groundwater injection for groundwater recharge at industrial sites.”

Texas evaluates projects on a case-by-case basis and has implemented several, says Steve Katz, senior market developer, SUEZ Water Technologies & Solutions. “California has released guidelines for groundwater replenishment and is working [on] finalizing guidelines for surface water augmentation.”

The Hamby Water Reclamation Facility (WRF) in Abilene, TX, is a great example of indirect potable reuse in action, Katz says. The WRF uses MBR technology to provide potable water reuse as a means to sustainably augment their freshwater supplies. “The region was experiencing chronic drought [which], accompanied by population growth, caused freshwater reservoirs to drop to only 30% capacity,” recalls Katz. “Residents were under strict water use restrictions due to drought.” By upgrading the Hamby WRF, the City of Abilene now generates more than 7 million gallons per day of advanced treated water to discharge into Lake Fort Phantom Hill reservoir to replenish their potable water supply.

The PUB in Singapore will also use water from their NEWater factories to augment their potable water supply when significant drought conditions exist. Bedok NEWater in Singapore provides tertiary treatment of wastewater for RO pretreatment and water reclamation. “Singapore has an integrated plan for water recycling that involves several NEWater factories supplying suitable reclaimed water for mainly industrial reuse,” says Katz. “The Bedok facility employs a multi-barrier approach of ZeeWeed ultrafiltration membranes from SUEZ, reverse osmosis, and ultraviolet treatment.” The ZeeWeed portion of the Bedok NEWater factory has an initial production capacity of 11.3 mgd (42,775 m³/d). ZeeWeed membranes remove suspended solids and colloidal material more reliably, and with the use of fewer chemicals.

Advances in membrane filtration have made membrane-based processes especially attractive for reuse applications. In fact, Alito says, California regulations require membrane treatment (although the state is currently testing ozone to see if it meets regulations).

Thanks to advances in technology, membrane filtration is enjoying popularity in treatment approaches for nonpotable and potable reuse applications. According to Water Reuse: Potential for Expanding the Nation’s Water Supply Through Reuse of Municipal Wastewater, a consensus study report published by the National Academies Press, membranes have a smaller space requirement, reduced labor requirement, ease of process automation, more effective pathogen removal (particularly of protozoa and bacteria), consistent effluent quality, and potentially reduced chemical demand.

The drawbacks of this technology include potentially higher capital costs, the limited lifespan of membranes, the complexity of the operation, and the potential for irreversible membrane fouling that reduces productivity. Unlike robust conventional media filters, membrane systems require a higher degree of maintenance and strategies directed to achieve optimal performance.

The Sulaibiya facility near Kuwait City, Kuwait, is the world’s largest membrane-based water reclamation facility. “The reclaimed and desalinated water from the Sulaibiya facility is used for nonpotable uses that impact the drinking water supply by blending with brackish water to better exploit existing brackish water distribution facilities,” explains Katz. The water reclamation plant is designed to treat 112 mgd (425,000 m³/day) of secondary effluent, which is pre-filtered with disc filters and then fed to the ultrafiltration (UF) system. The UF product feeds a reverse osmosis plant, and UF waste is recycled to the wastewater treatment plant (WWTP). The UF system treats 100% of the flow after biological treatment since the UF waste is recycled. Therefore, the feed to the reverse osmosis (RO) system is also 100 mgd (375,000 m³/day). The RO plant is designed for 85% water recovery, so the expected production rate is 85 mgd (318,750 m³/day).

Several US states are pursuing development of guidelines, the World Health Organization has published recommendations, and validation protocols for various technologies have been released in Australia.

Groundwater renewal system microfiltration facility

TYPES OF REUSE TECHNOLOGY

The latest in water reuse/recycling technology is not so much the technology itself but how that technology is being applied, Katz states. “Today, we have the technology to safely recycle any wastewater back to the highest standards of use. This puts us in a position to put together various unit operations into flowsheets, which are tailored to the end-use of the recovered water. SUEZ offers a wide variety of water reuse technologies that fit into various reuse flow sheets.”

It’s important to make “the safest water possible,” interjects Alito. When the public is confident of that, there is less resistance. “We didn’t encounter public objection in Virginia like we expected,” she recalls, crediting education of the public. “We were transparent and got the public involved early. When you need water to build a treatment site, you also need to plan long-term to support the community and make water safe.” Ultimately, she says, it is possible to lower operating and maintenance costs while maintaining high quality with minimal risk if you use the right technology.

According to the National Academies Press report, many factors affect the choice of water reclamation technology. Key factors include the type of water reuse application, reclaimed water quality objectives, the wastewater characteristics of the source water, compatibility with existing conditions, process flexibility, operating and maintenance requirements, energy and chemical requirements, personnel and staffing requirements, residual disposal options, and environmental constraints. Decisions on treatment design are also impacted by water rights, economics, institutional issues, and public confidence.

Treatment processes in wastewater reclamation are employed either singly or in combination to achieve reclaimed water quality goals. Those processes include:

- Membrane Bioreactor Solutions – These combine biological, secondary, and tertiary wastewater treatment in one step and have been used not only to treat wastewater to high effluent quality standards for over 25 years but also represent a well-established means of enabling the reuse of wastewater.

- Ultrafiltration Solutions – Used for drinking water and tertiary treatment, UF systems are designed to operate downstream of a secondary wastewater treatment process, where no further biological treatment is necessary but where high-quality water is required. The system features a small footprint that can be placed virtually anywhere or can even be used to retrofit existing granular filter media.

- Reverse Osmosis Systems – RO systems are typically used after the water has been pre-treated to remove organics, suspended solids, and metals that may oxidize or precipitate on the membranes. Pretreated water is sent to an RO for desalination for drinking water, water reuse, or as part of a system to produce ultrapure water. RO is selected for indirect and direct potable water reuse applications because it provides an excellent barrier to bacteria and pathogens and can remove pesticides, in addition to providing water with low TDS.

- Disinfection Technologies including UV / Ozone / Advanced Oxidation – These processes are used as a final step in water reuse applications to reduce TOC and destruct any remaining organics.

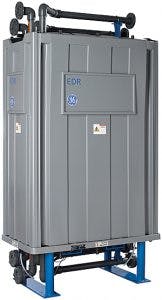

- Electrodialysis Reversal – This is an electrically driven membrane process that uses an electric voltage to draw ions through membranes. Because of the polarity reversal design, EDR is a self-cleaning, durable membrane system ideal for turbid wastewater. EDR technology achieves the highest water recovery for water-scarce areas.

- Thermal Evaporation and Crystallization Systems – These systems are essential for achieving zero liquid discharge and recycling the last bit of wastewater. With any wastewater reuse system, there are often a few remaining wastewater streams too saturated for conventional physical/chemical and membrane technology. Evaporation and crystallization reduce these last difficult wastewaters to dry solids, allowing for cost-effective disposal and squeezing out the last bit of clean water for maximum recycle and reuse.

Changing out UV lamps

A focus still exists on delivering step changes in performance and efficiency of technologies, as this is critical to the water industry, Katz notes. He adds that SUEZ is focused on the challenge to reduce the holistic cost of ownership of their treatment solutions.

One new alternative that can reduce maintenance costs is ozone biofiltration. “There’s no need for an operator—the burden with the membranes,” says Alito. “High pressure/high energy systems are expensive and they produce a brine stream and a waste stream, which must be treated separately. Ozone biofiltration doesn’t produce a waste stream.”

She says it’s been widely used for 10 years but is currently being validated for reuse applications because “the water coming out of a reclamation facility has different properties.” Several utilities are currently pilot-testing it now.

The advantages include the fact that it quickly breaks down large molecules from source water, including biodegrading contaminants and pathogens. “The process is like drinking water treatment,” elaborates Alito. “It’s upstream treatment. You apply a dose of ozone to break down large organisms and biodegradable molecules.” The biggest maintenance cost is replacing the media: granular activated carbon. The rate depends on the system.

Electrodialysis Reversal

or EDR uses an electric

voltage to draw ions

through membranes.

APPLICATIONS

SUEZ has several water reuse projects using key reuse technologies. In addition to those already mentioned, the Federated Co-operatives Limited’s Co-op Refinery Complex (CRC) in Regina, Saskatchewan (SK), Canada uses SUEZ’s advanced technologies. It has become the first refinery in North America to treat 100% of its wastewater onsite and then recycle the treated effluent for steam production.

In 2013, the refinery was expanded to process 130,000 barrels per day, resulting in an increase in the water requirements. The refinery’s current water source is a blend of well water and city water, with restrictions on water use, due to regional scarcity, population growth in Regina, and other local industrial demands that mandated that CRC find a new source of water. The overall solution combines oil-water separation, dissolved gas floatation, and membrane bioreactor technology, followed by a boiler feed demineralization plant that includes ion exchange and a high-pH reverse osmosis system.

Two million gallons of wastewater are recycled per day, reducing the facility’s freshwater requirements by 64% and saving enough water for 3,100 households. In addition to the water reuse solution, SUEZ provides the refinery with wastewater specialty chemicals and monitoring solutions to provide system optimization.

TECHNOLOGY EVOLUTION

There are a few key high-level industry shifts underway. What was once thought of as waste is now being re-evaluated for its value, changing the focus to resource recovery.

Typically, a wastewater stream contains organic fuel, nutrients, and water. The industry is moving toward efficient extraction of these valuable products and technologies are being developed to do this job.

“The energy content of municipal sewage is 2–4 times greater than the energy required to treat it,” says Katz. “It is an unexploited resource that current technologies and practices do not fully capitalize.” However, there’s an opportunity to transform wastewater facilities into resource recovery factories capable of generating energy through modifications to current practices and the adoption of new disruptive technologies. Among those disruptive technologies are:

- Enhanced primary treatment – Considerable energy is needed to treat suspended organics. By shunting them away from biological secondary treatment to sludge treatment, facilities can reduce consumption while increasing energy production.

- Ultra-low energy biological treatment – Discharging water that meets rigorous quality requirements is the most energy-demanding part of wastewater treatment. Microbes in this process require oxygen to metabolize the organics and nutrients.

- Advanced sludge treatment – The organics shunted from the biological process are processed through advanced anaerobic digestion, converting sludge into biogas that can then be converted to electricity, while producing biosolids for agriculture or other beneficial use.

- Energy recovery – Biogas produced during advanced anaerobic digestion is converted into electricity and heat by gas engines or recovered as natural gas.

Thermal Evaporator systems are essential for achieving zero liquid discharge and recycling the last bit of wastewater.

FRESH APPROACH

The availability of freshwater is negatively impacted by environmental impacts such as drought, as well as population growth, urbanization, contamination of existing water supplies, industrial growth, and agricultural demands.

According to some sources, globally we will need 40% more water by 2030. In order to maintain amounts required to meet demand, many jurisdictions have begun to prioritize a more resilient freshwater supply.

One way to combat increased demand and supply challenges is for industry and municipalities to look at safely reusing the water we have. Some may be forced to do so, as was the Co-op Refinery Complex in Regina, SK.

“Another trend we’re also seeing is a more integrated approach to recycling,” reveals Katz, “almost like a market for water needs.” He explains that there are local clusters of treatment facilities that feed water back out to various consumers for different uses. “This entails treating water to quality levels that are fit for the end-use purpose, which augments efficiency.”

One example of this is being implemented by West Basin Municipal Water District to tailor treatment for various uses at neighboring facilities in the El Segundo, CA, area. Uses of the water include irrigation, cooling tower make-up, boiler feed systems, seawater intrusion barrier, and groundwater replenishment. “The Public Utilities Board in Singapore are true leaders in water management,” praises Katz. “Their programs are entrenched in the society and are considered truly integral to their national security.”

A key pillar of their integrated plan for water supply and recycling involves several NEWater factories supplying suitable reclaimed water for mainly industrial reuse customers, such as the Bedok plan.

TREATMENT OPTIONS

There are many processes and theories of treatment, Alito states. Treatment options include engineered and managed processes to mitigate microbial and chemical contaminants in reclaimed water. This, according to the NAP report, facilitates a multitude of process combinations that can be designed to meet distinctive water quality objectives.

Hamby WRF in Abilene, TX, uses SUEZ MBR

technology to provide potable water reuse as

a means to sustainably augment their freshwater supplies.

Advanced treatment processes are able to address water quality issues related to potable reuse involving emerging pathogens or trace organic chemicals. However, the lack of clear standards is one of the biggest deterrents to the use of engineered natural systems for potable reuse applications.

Another inhibitor is the lack of knowledge about how operating conditions could be modified and retention times shortened to achieve a consistent water quality in a smaller footprint as engineered natural systems replace some advanced treatment unit processes. Additional research is needed.

That’s why Alito says it’s important for HDR to be at the forefront of the market, researching and understanding the technology. “Each utility has a different source water, treatment, and end-goal. We need the proper tools to evaluate each system individually.” To that end, she says HDR has research projects underway with 15 utilities to supply diverse input.

DIGITAL TRANSFORMATION

Katz says SUEZ has “only scratched the surface” regarding advances, claiming that their digital solutions to water treatment will “change the way we operate and maintain our infrastructure.” InSight, their asset performance management system, is a cloud-based interface that uses data and analytics to ensure that assets operate at higher levels of reliability, efficiency, and output.

The new enhancements include Geomap and asset fleet view on new dashboards, modernized user interface and navigation, multi-site reporting, and enhanced file management.

The benefits of these enhancements are expected to be more transparency and visibility into the operation, simplified navigation for ease of use, expanded reporting and file management that enables sharing of data at all levels, and faster access to data and reporting to eliminate or reduce unplanned downtime and lower operating costs. In short, this digital system is designed to help manage assets. “This will combine machine learning and analytics with real-time modeling and data collection,” says Katz.

It doesn’t end there. Katz vows, “We will better monitor processes, allowing us to react, learn, and operate more efficiently.” It’s important to use technology not only to process reclaimed water but to manage the process. “With the clear need for sustainable sources of freshwater, growth in public acceptance, developing regulations, and the technology that exists to reuse water safely, it is anticipated that the reuse of wastewater for human consumption will grow.”

Katz concludes by quoting Dr. Lucas Van Vuuren of the National Institute of Research in South Africa, who said, “Water should not be judged by its history, but by its quality,” adding that he believes this premise grounds them as water experts and guides their focus. After all, you can’t make new water. we

REFERENCES

www.nap.edu/read/13303/chapter/6#82 www.epa.gov/region9/water/recycling