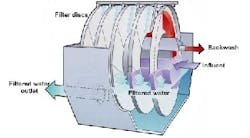

Click here to enlarge imageDuring normal operation, the discs remain static until the level in the inlet channels rises to a certain level. When this occurs, the backwash cycle automatically is started and solids are back-washed into the collection trough as the discs are rotated. A counter-current flow path and moving spray headers ensure thorough cleaning of the filter media with minimal water use. Typically, the backwash requires around 5 percent of the flow to the filter. The backwash spray headers fold out to facilitate maintenance of the spray nozzles that can be removed and replaced without any tools.

The modular filter panels consist of woven filter media, either polyester or stainless steel, which is held within a stainless steel frame. Because the filter media is a woven material, precise pore sizes allow for better filtration than non-woven media that provide an "average" pore size. The woven filter media is available in pore sizes ranging between 5

The filter panels are secured to the disc by a single clamp allowing for easy replacement that does not require large-scale or expensive service. If there is a change in operating or performance needs, the design accommodates an easy switch to a filter media with a different size opening. Depending on the application, the filter panels will only require replacement every 3 to 5 years.

Because the filter discs operate at around 60 percent submergence, there is easy access for inspection and replacement of the panels. There is space for up to 10 discs on the largest size, however a filter can be installed with fewer discs with more being added as flow rates increase.