Tackling High TTHM from an Operator's Perspective

By Levi Sturgill

Disinfection byproducts (DBPs) are chemical compounds formed by the reaction of a disinfectant (chlorine) with a precursor (natural organic matter) during the treatment process at water plants. The two EPA-regulated categories of DBPs are total trihalomethanes (TTHMs) and haloacetic acids (HAA5s). These compounds, at high levels, have been proven to contain carcinogens. For this reason, the EPA lowered already established limits to a locational running annual average of 80 ppb, forcing water plants to look for alternative treatment methods. This caused a problem in many water plants because disinfection is vital in the treatment process but at the same time caused higher levels of DBPs. People involved in the water treatment community started looking for solutions to this problem. The following is my experience in tackling high TTHMs.

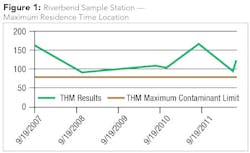

I am a Class III water plant operator working at St. Albans Municipal Utility Commission in West Virginia. At our plant, we had a serious problem with TTHMs, sometimes with results almost three times the legal limits. Starting in 2007, some of our first testing results were in the 160 ppb range and continued to stay there (see Fig. 1). I had to come up with solutions to lower these numbers immediately.

In 2011, our plant was selected to participate in a special study with the EPA and the West Virginia Department of Health and Human Resources’ Office of Environmental Health Services (WVDHHR/OEHS). This special study was specifically created to research and find solutions for DBP removal. Over two years, the study group met quarterly and was very beneficial to me and our water system.

Our first step was to make some treatment changes in the plant. I started with the reduction of pre-chlorine feed, the addition of a carbon feed system, and optimization of the potassium permanganate feed. These minor changes alone made a sizable impact on our TTHM levels, but we still had issues in the warmer months.

While participating in the study and through research and field testing, we found that aeration was the best way to remove TTHMs after they are formed. In fact, many systems have been installing aeration systems in the distribution tanks. This led me to my next step: I would install one aeration system in the clearwell of our plant and - with an initial start-up cost of $3,500 and an annual cost of $600 - save the system money. My reasoning was that if I could reduce TTHMs in the plant by putting an aeration system in the clearwell, it would in turn lead to a reduction in the distribution system.

I chose to use a spray system. This type of system uses special spray nozzles that disperse the water in tiny beads, which strip the TTHMs from the water. At the same time, this mixes the clearwell and turns it over, also reducing TTHMs. I installed two spray nozzles in the clearwell to cover the whole area of the water. The pump used for spraying is wired to a timer that runs on three-hour intervals throughout the day. Given the size and flow of the pump, this timing turns over our clearwell twice in three hours. This optimizes the TTHM removal process by insuring maximum turnover rates and spray time.

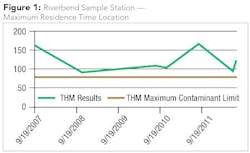

After the system was installed, I conducted my own special study to determine what removal rate was being achieved. Using the Hach DR3900 and the Hach THM Plus Method, keeping all other variables constant, I ran two tests every morning for a week with the aeration system completely shut off. The next week, keeping all other variables constant, I ran two tests every morning with the aeration system running (see Fig. 2). These results, along with required compliance testing results, showed removal rates exceeding 40 percent. My original hypothesis was correct in that by removing TTHMs in the plant, it also reduced them in the system. That quarter’s compliance testing results were the lowest we had ever seen in over seven years of testing.

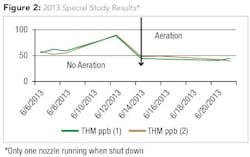

Since installing this aeration system, we have been below the regulated limits of TTHMs every time we have tested. When we started testing, our annual averages were in a range of 60 ppb to well over 100 ppb. In our 2014 compliance sampling period, annual averages were in the 30-40 ppb range (see Table 1).

Table 1. First Quarter 2014 Compliance Results*

I have made a few additional treatment changes that have further lowered our TTHM levels, including further reducing pre-chlorine feed and moving the potassium permanganate feed point closer to the intake of our plant. Moving the feed point has almost doubled the contact time of the potassium permanganate, resulting in the ability to increase the feed rate and remove more natural organic matter from the raw water before chlorine is added. This has further reduced TTHM formation (see Table 2).

With all of these treatment changes and the addition of aeration, the removal of TTHMs is consistently 40-45 percent better than it was only two years ago. We have been under the legal limits every time we have sampled. My conclusion is that if you have challenges with TTHMs, making simple treatment changes and adding an aeration system will help you tackle your TTHM problem and make life in the water plant a lot easier.

About the Author: Levi Sturgill is a Class III water plant operator working St. Albans Municipal Utility Commission in West Virginia. He can be reached via email at [email protected].

More WaterWorld Current Issue Articles

More WaterWorld Archives Issue Articles