By Ludwig Dinkloh

Globally, the use of ultraviolet radiation to disinfect in reuse applications is growing rapidly due to its economical and ecological advantages over chemical disinfection with chlorine-related products.

The design engineer, however, is faced with an increasingly complex market due to different UV technologies being offered, such as different lamps, configurations, control philosophies, and monitoring capabilities. Foremost, local legislation influences preliminary designs, but then engineers determine the final stage either using a standardised mathematical or bioassay approach. The National Water Research Institute (NWRI) and American Water Works Association Research Foundation (AWWRF) — "UV Disinfection Guidelines for Drinking Water and Water Reuse" presents a conservative basis for a bioassay approach and

The largest UV systems in operation for drinking water use low pressure-high intensity lamps, such as in Manukau, New Zealand.Photo by Wedeco

may not be applicable to every reuse project involving UV. However the technology exists to fulfil the guideline's requirements, including performance monitoring.

Disinfection is an essential step in the treatment process for any type of water reuse that leads to direct or indirect exposure of humans to treated water. Similar to modern drinking water treatment plans, the disinfection of wastewater for reuse purposes may not solely depend on a single technology, but employ a combination of disinfection processes - the so-called "multi-barrier" approach.

Both UV intensity and exposure time need to be uniform and exactly measurable to determine a definable UV dose responsible for a certain microbiological effect. This is possible with a collimated beam device. These devices are being used more frequently as calibration methods for certification/validation purposes of UV reactors. Irradiating a wastewater sample, which should have undergone all treatment steps prior to UV disinfection with a collimated beam device, leads to project-specific inactivation curves of the analysed microorganism.

Besides the disinfection requirement, several other parameters need to be known before accurately designing and sizing UV systems: flow rate (maximum, average and minimum); maximum inlet concentration of target organisms; effluent quality (BOD, COD, suspended solids and UV transmittance).

TakBank of the world's largest UV wastewater disinfection plant at Manukau, New Zealand.

Since reuse standards are typically very stringent, special attention must be given to two parameters that have the strongest effect on UV design and performance - suspended solids and UV transmittance.

Effects of suspended solids in wastewater on UV disinfection are similar to that observed in chlorine disinfection. Shading limits the exposure of individual and particle-associated microorganisms to UV light. Scattering and absorption of UV radiation limits the exposure of particle-associated micro-organisms to UV light. While the quantity of suspended solids is of concern, the real challenge lies with microorganisms located within particles. They, in return, are a function of the upstream treatment process.

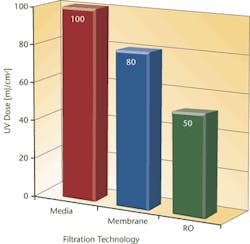

In general, filtration improves UV disinfection performance to achieve lower microorganism counts. Depending on the disinfection goal, wastewater particle size distribution and the particle sizes removed by the filter should be obtained to ensure an adequate reduction in the number of particles with associated microorganisms to achieve desired results. NWRI/AWWARF guidelines define different minimum dose levels depending on the type of filtration technology used prior to UV treatment.

While suspended solids affect UV performance in allowing or preventing the UV system to achieve a certain disinfection goal, UV transmittance does not limit the system effect. However, the lower the UV transmittance, the more lamps (consequently, more energy) are required to apply the same UV dose.

UV dose rates depending on upstream filtration

The determination of UV transmittance is therefore a critical step in UV disinfection design. Additionally, it would be beneficial for a UV system to be capable of reacting accurately to water quality changes by, for example, increasing UV intensity at lower than design UV transmittance values.

Currently, all commercially available UV lamps rely on a mercury discharge. The two lamp technologies - low- and medium-pressure lamps differ in the partial pressure of mercury and corresponding output spectrum. The market share of "low pressure-high intensity" lamps has grown dramatically in the past few years. The largest UV systems in operation for drinking water (Helsinki, Finland) and wastewater (Manukau, New Zealand) use this lamp technology.

One example of a low pressure-low intensity lamp is the G64T5 manufactured by various lamp suppliers. Its characteristics include an arc length of 58 inches and an UV output at 254 nm at the beginning of lamplife of 27 W, which leads to a specific output of 0.46 W/inch. Any low pressure lamp that has a higher specific output than 0.46 W/inch can be called a low pressure - high intensity lamp.

The Germany company Advanced UV Light GmbH produces low pressure - high intensity lamps under the brand name Spektrotherm®. These lamps are amalgam lamps as the mercury is, in contrast to conventional low pressure lamps or medium pressure lamps, not introduced in liquid form but in a solid state (an amalgam in combination with indium). The currently most powerful Spektrotherm lamp, type SLR32143, produces UV output of 125 watts (W) with an arc length of 56.3 inches, leading to a specific output of 2.22 W/inch, almost five times more powerful than the G64T5.

The open channel/gravity flow design is the most widely used wastewater UV disinfection design. A second design option is using pressurised vessels. This can be required due to the upstream filtration requiring a certain pressure to operate and/or the wish to directly transport the disinfected effluent under pressure to the point of reuse.

Weirs in wastewater treatment facility in Manukau, New Zealand.

Hydraulic devices play an important role in the perform-ance even though closed vessel reactors do not require a level control device. In order for UV systems to properly function, the same requirements for magnetic flowmeters should be applied in free upstream and downstream piping. Baffle plates direct flow in a desired direction, so they can reduce those requirements.

Strict standards can be achieved with UV systems in an economical and environmentally sound way given that effluent quality physically allows UV radiation to reach microorganisms of concern. While members of the coliform species are typically used as indicator organisms; the US states of Arizona, California and Hawaii have also added a viral requirement to their reuse standards.

The selection of the UV disinfection system can be based on project-specific performance needs in case the design is not governed by a validation/approval protocol. A collimated beam analysis of the effluent will determine the minimum UV dose level necessary or may indicate that pre-treatment needs to be improved in order for UV to achieve the goal. UV transmittance tests will determine UV transmittance ranges of the effluent.

The engineer can then apply project-specific safety factors to establish the design UV dose and the design UV transmittance at the peak design flow. Wastewater reuse plants in planning or under construction will obviously rely on the experience of the engineer to specify realistic design values without being able to confirm these with collimated beam tests and UV transmittance measurements.

The required minimum UV dose can then be determined in two ways: mathematically, including project-specific safety factors based upon a standard calculation method; via a bioassay, including project-specific safety factors based upon a standard bioassay protocol.

Both approaches require the engineer to specify a uniform standard, which is especially important when comparing different UV systems that are not as readily discerned in a mathematical model. The differences between these methods are rapidly shrinking as Computational Fluid Dynamics (CFD) advances.

Continuous performance monitoring of UV equipment is also covered in the NWRI/AWWARF guidelines. The performance of an UV system is determined by the operational UV dose, which is theoretically arrived at by multiplying UV intensity with exposure time.

During pilot testing, minimum UV intensity readings are established via UV sensors. They must account for UV intensity field geometry, possible scaling of the lamp sleeve and the influence of water UV absorbency. Additionally, the UV manufacturer must provide reference sensors that can be used to verify the accuracy of the UV intensity sensors. Exposure times are basically translated into lamp loadings combined with velocity profiles.

The performance (or application of specific UV dose) is guaranteed given that lamp loading is equal or below the maximum loading arrived at during pilot tests, and UV intensity recorded by the UV intensity sensor is equal or above the minimum UV intensity value established during pilot tests. UV systems with variable output lamps can make use of the minimum intensity reading by actually dimming down the lamps to the minimum value, thus saving energy and lamp life.

Author's note

Ludwig Dinkloh is the sales director for municipal products at Wedeco-Ideal Horizons, located in Charlotte, North Carolina, USA.

Wedeco TAK55 system receives Title 22 acceptance

Wedeco is the first UV manufacturer to receive conditional acceptance for the disinfection of filtered wastewater for water recycling by the California Department of Health Services (DHS) and the Hawaii Department of Health. Wedeco submitted bioassay test results and hydraulic results from its pilot plant at Orange County Water District in California in accordance with the NWRI/AWWARF guidelines to the DHS, to meet the state's Title 22 reuse standards. California and Hawaii adopted these guidelines as the design basis for UV systems.

Its pilot plant results can be used to upscale the design of larger installations. The guidelines limit the factor of upscaling to 10 times the number of lamps used in the test reactor.