Commercial growers, property managers, and landscapers can attest to how sophisticated and beneficial irrigation monitoring has become in terms of optimizing water consumption and plant growth, and maximizing operational profitability. Two examples from California—where much of the nation’s food supply is produced but where water availability remains a critical public policy issue—illustrate how irrigation monitoring and control systems can serve as a valuable business tool.

Larry Peltzer, a fourth-generation citrus grower and owner of LRP Orange Co. in Visalia, CA, reduced watering time and frequency and improved water efficiency by up to 40% by using wireless irrigation monitoring stations that collect real-time soil moisture data. The company monitors soil moisture trends through the profile on iPads and mobile phones and decided to extend its irrigation cycle to every 12–15 days, as opposed to every seven to nine days. According to Peltzer, extending the cycle allowed LRP to reduce water use by 30–40%.

Peltzer explains that the need for irrigation monitoring arose from a lack of available surface water and depletion of LRP’s underground water supply. Due to those challenges, the company focused on ensuring maximum efficiency in terms of irrigation timing and water volume application. Peltzer adopted Rain Bird’s ClimateMinder system, which was installed and maintained by Irrigation Matters of Tulare, CA. He says that the system has allowed LRP to irrigate less by eliminating guesswork. By using the system, LRP has become more efficient with its water usage and fertilizer application and has also saved on fuel and labor, reports Peltzer. The efficiency increase was clearly due to Irrigation Matters’ interpretation of the ClimateMinder system data and work with the grower to make operational adjustments.

Additionally, LRP increased its crop yield by 15–20% due, in part, to the use of the system. The yield increased to 60-plus bins per acre in 2014, compared with 50-plus bins per acre the previous year. Peltzer and LRP found that the system made the yield increase possible by helping the company reduce the risk of root disease development that otherwise would occur from excessive soil moisture levels. Also, avoiding overwatering ensures that applied nutrients stay in the root zone.

Like many growers, LRP also uses the system to continuously monitor the changes in electrical conductivity (EC) to make sure they are not pushing their fertilizers below the root zone. By taking bulk and pore EC measurements, the company can tell the distance that liquid fertilizer penetrates when it fertigates. Now, LRP is able to keep fertilizer in the root zone. Pointing out that the state is watching nitrate applications closely, Peltzer notes that the company will have evidence to show that it is not abusing its nitrogen applications.

A historic drought in the western United States promises to challenge Peltzer and LRP for at least the next few years. Given the lack of surface water, he acknowledged that his company needs to manage available water as efficiently as possible. One of his ranches has no wells and LRP is allocated only 90 days of surface water. As a result, the company is harvesting its Valencia oranges to take the load off the trees so that they can survive the drought. Use of irrigation monitoring is critical to the survival of operations like LRP.

The need to optimize water use is not confined to produce growers such as Larry Peltzer. Commercial landscapers tasked with keeping building grounds looking green and vibrant need to do so without excessive water consumption. In 2012, Dennis Bryan, president of Water Savers, a water-auditing and consultation company in central California, got a call from a property management company in central California that was struggling to achieve such a balance.

One of the company’s properties was using an excessive volume of irrigation water to maintain vibrant greenery. The appearance of the property was critical to the property owner, but the property manager was getting socked with water bills totaling thousands of dollars every month. A particularly problematic aspect of the billing was that the water rates were graduated, so the rate escalated as consumption increased. The property manager knew that something needed to be done, and fast. He reached out to Water Savers to see if the company could suggest a way to correct the situation.

After completing a site survey, Bryan came up with a solution: deploy a closed-loop irrigation system utilizing Acclima soil moisture sensors and controllers. This system would give the lawn precisely the amount of water needed. Bryan had installed similar systems on other properties and obtained significant savings for the property owners.

At this site, Water Savers installed five controllers and one or two sensors per controller. The system yielded an economic benefit in the first month, one that surprised Bryan, who has a great deal of experience with such systems. Within the first month of installation, the system yielded a savings of 85% compared with the same month the previous year. Further, after 10 months of system utilization, the average savings were about 40–50%. A supplementary benefit of installing the system was that it allowed Water Savers to identify weak points in the system, i.e., weak sprinkler heads. The company replaced those sprinkler heads with units that provided more even distribution of water over the property, contributing to the savings.

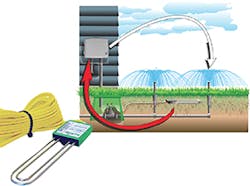

Right: Acclima’s closed-loop irrigation system uses datacollected by the sensors to set the optimalmoisture threshold. The controller applies waterif the moisture reading is lower than the threshold.Left: Acclima’s SDI-12 Digital TDT soil moisture sensor

Optimization Relies on Soil Moisture Sensors

Ultimately, irrigation monitoring systems are all about receiving optimal outputs (plant growth, operational profitability) from optimal inputs (water and fertilizer). More and more users are becoming aware that the Law of Diminishing Returns applies to the application of these inputs after a certain threshold. Monitoring systems serve the valuable role of identifying where optimal input thresholds exist. Finding that threshold and adjusting inputs accordingly results in successful growing and resource management—the latter is increasingly critical as some inputs become more scarce and regulations governing their use grow stricter in many parts of the country.

The idea of actually reducing inputs and getting healthier plants does take some getting used to, according to Acclima’s founder and chairman, Scott Anderson. He notes that many of his customers reap the benefits of water and financial savings by using his irrigation monitoring systems and certainly appreciate them. But, says Anderson, many customers are surprised to see that their lawns and plants become healthier, and greener. Acclima helps these customers to understand that less water allows plants’ roots receive more oxygen and nutrients, the latter of which do not get washed away into the subsoil.

True irrigation monitoring that allows optimization of inputs based on soil moisture content rather than programmed watering times relies on the use of a critical component of a monitoring system: the soil moisture sensor. This unit signals an irrigation controller when to water plants via sprinklers, drip irrigation tubing, and the like. Increasingly, wireless telemetry stations tie together systems on multiple sites, giving irrigation managers the ability to monitor the sites from a central location.

In late 2012, Rain Bird acquired the ClimateMinder system, which consists of sensors, wireless telemetry stations, and controllers. The system is designed with multi-platform control, i.e., users can control pumps, valves, and fertilizer injectors using a phone, computer, or tablet. Alerts can be set up for sudden changes to field conditions and it is possible to set up daily or weekly reports of field conditions.

In 2014, Rain Bird released a multi-ranch dashboard that allows growers to review field data from all of their weather and soil moisture stations using a Web-enabled computer or mobile device. The data from multiple locations are displayed on one Web page. The information is based on geolocation that identifies areas that require attention in the form of colored map icons and soil moisture indicators Automated applied water reports for the multiple locations can be sent to the Natural Resource Conservation Agency or other regulatory agencies.

Rain Bird reports that it offers growers a choice of the approach to determining plant water needs: measuring the total water volume in the soil or measuring the water potential or tension. The ClimateMinder System measures EC, soil moisture, and soil temperature in real time. EC measurement merits explanation. The salinity level of water impacts EC, which impacts plant growth in two ways. First, the specific toxicity of a particular ion such as sodium can affect plant growth. Second, higher osmotic pressure around the roots prevents efficient water absorption by the plant.

Rain Bird’s ClimateMinder system measures the total water volume in the soil, or the water potential

The ClimateMinder system is equipped with multi-sensor profile probes, water potential sensors, and tensiometers, the latter of which measures the tension or suction that plants’ roots must exert to extract water from the soil. This tension is a direct measure of the availability of water to a plant.

The system uses evapotranspiration or tension data to help growers determine how much water is needed and EC measurements in the soil indicate the necessary level of fertigation.

The manufacturer’s profile probe, designed for use with most permanent crops, can be buried up to 5 feet below grade, allowing for measurements of deep water and application management. Its MPS-2 dielectric water potential and temperature sensor is designed to be maintenance-free and measure a wide range of soil water potentials.

Rain Bird also offers three models of volumetric water content (VWC) sensors. The 10HS Soil Moisture Sensor measures VWC only. The three-pronged 5TE Soil Moisture Sensor measures VWC, temperature, and EC using high-frequency oscillation and patented signal filtering. A new model, the GS3 Soil Moisture Sensor, also measures VWC, temperature, and EC, and has stainless steel needles with extended surface area to optimize EC measurements and minimize substrate disturbance during insertion.

Rain Bird has two models of controllers: the ClimateMinder and the ESP-LX Series. Both controllers have a built-in cellular modem for remote access through a Web interface on a computer or device such as iPhone or iPad. The ESP-LXME is expandable from eight to 48 stations with four module slots compatible with eight-station or 12-station modules. The ESP-LXD has the capacity to expand from 50 stations to up to 200 stations.

Rain Bird ClimateMinder wireless weather and soil moisture station

Acclima’s irrigation control systems are designed for either research or closed-loop commercial turf irrigation applications. SDI-12 soil-moisture/EC temperature sensors suit the former category and the SC24/36 Irrigation Controller and 24-volt time domain transmissometry (TDT) sensor suit the latter.

The SDI-12 sensor, used in research applications, is equipped with Digital TDT technology. The TDT principle is based on measuring the time it takes an electromagnetic wave to follow a waveguide, i.e., electromagnetic feed line, through the soil. The waveform is digitized to exclude the effects of EC, which can cause inaccurate readings that lead to significant over- or under-watering, thus providing a reliable reading of the volumetric soil moisture content.

The portable DataSnap SDI-12 data logger accommodates as many as 10 SDI-12 sensors. Acclima’s SnapView software manages multiple connections and can display data in either tabular or graph formats. The data logger also allows growers to take manual readings.

Another Acclima soil moisture sensor, the TDR-315, is a Time Domain Reflectometer (TDR). Its sensor head is equipped with a microcomputer with preloaded interpreting software. The sensor reports soil volumetric water content (VWC), temperature, permittivity (an electrical characteristic of soil that indicates its VWC), and EC, which can be a marker for nitrogen in the soil.

The TDR-315 uses a three-element waveguide embedded in the soil. A fast-rising electromagnetic wave is propagated down the center electrode and reflects back off the end. According to Steve Evett, a US Department of Agriculture (USDA) soil scientist, this time measurement accurately yields the volumetric water content of the soil. This allows a determination of the rate of water uptake through the soil to plant roots.

Evett reports that soil scientists at the USDA have determined that the sensor’s response is essentially identical to traditional TDR but has significantly less attenuation than traditional TDR, which uses a separate console, step function generator, and coaxial cable that signals the console. The coaxial cable attenuates the wave and makes readings much less resolving. The TDR-315 is designed to eliminate the need for the separate system components and reduce the attenuation of traditional TDR. The manufacturer’s website cites studies featuring its TDR and TDT sensors, including those made public at the MOISST conference at Oklahoma State University in 2015, a 2005 Journal of Hydrology article, and the 24th Annual Central Plains Irrigation Conference in Colby, KS, in 2012.

Used in closed-loop irrigation applications, the manufacturer’s 24-volt version of the Digital TDT Sensor reads soil water content, soil temperature, and soil conductivity and is designed for permanent installation without the need for maintenance. It includes an internal zone switch for wiring into a nearby valve box. Using patented digital TDT technology, the unit measures the travel time of electromagnetic pulses through the soil from which permittivity and water content are calculated.

The manufacturer refers to a study by Diganta Adhikari and Dave Goorahoo of the California State University, Fresno Center for Irrigation Technology, “Response of Acclima Digital TDT probe to Soil Moisture and Electrical Conductivity,” on the accuracy of the Digital TDT sensor on sandy loam soils holding varying degrees of EC, i.e. fertilizers.

Mazzei Injector Corp.’s differential pressure injector is designed to facilitate fertigation.

Acclima’s closed-loop irrigation controllers receive feedback from Acclima irrigation sensors. They operate off of 24 volts of alternating current and communicate over a proprietary protocol. SC24 and SC36 controllers support 0 to 24 or 36 soil moisture sensors, respectively, with sensor sharing, which allows control of multiple zones by a single sensor and simultaneous watering of up to four zones. The units suit both drip zones and spray zones. Growers set each zone to sensor or timed control; for the former, the controller uses data from Digital TDT moisture sensors. Seasonal water budgets accommodate timed zones. Each sensor adds a sensor program to the system with six start times each and up to 40 total programs are available. Growers can program custom, daily, odd day, even day, and every -nth day watering with “n” ranging from two to 31 days. Acclima cites a four-year University of Florida study revealing the water savings and fully automated quality of its closed-loop irrigation system.

Acclima soil moisture sensors and controllers work together to monitor and control the moisture of the root zone of lawns and other landscape plants. Using data collected by the sensors, the optimal moisture threshold is set to the percentage equivalent to slightly below the field capacity, i.e., moisture holding capacity of the soil. The controller applies water if the moisture reading is lower than the threshold.

Regulations Drive Fertigation Developments

Moisture sensors that measure soil properties such as EC give growers a tool for practicing fertigation—applying fertilizer in water only as it is needed at the plant root zone to maximize plant absorption and reduce runoff. The increasing importance of water resource protection will drive the development of new regulations and thus future developments in fertigation, according to Mazzei Injector Corp., a provider of mixing and contacting technologies for irrigation chemigation, and fertigation.

Mazzei cites instances of fertilizer runoff into surface waters causing the eutrophication of the receiving water bodies, killing fish, and causing algal blooms that have threatened drinking water supplies. Toledo, OH, experienced this with Lake Erie in 2014. California has enacted the Sustainable Groundwater Management Act to protect its diminishing groundwater supplies from continued contamination by directing farmers to track and record their fertilizer, nutrient, and pesticide inputs. Compliance will require more precise application of these crop inputs with a focus on the recordkeeping aspect of the fertigation technology.

The company’s Venturi differential pressure injector is equipped with internal mixing vanes. The unit is designed to maximize injector efficiency, suction capacity, and mixing capabilities to yield even distribution of product throughout the irrigation system. The absence of moving parts is intended to result in lower maintenance.

The manufacturer reports that it has developed a prototype of a new injector technology called Tru-Blend, a proportional feed fertigation system that “spoon feeds” plants a precise amount of fertilizer through the growing cycle, enhancing crop nutrition and safeguarding water supplies. Mazzei plans to field-test the new technology this year.