Leaks are never good, whether it’s a leaky boat or a leaky pipe system. Even advanced water utility systems can experience water loses ranging from 10 to 40%, with these losses being proportional to the population of the urban area serviced by the water distribution system. Large cities like New York, Beijing, and London are vulnerable to staggering amounts of water losses in absolute terms. It represents both a significant loss of resources and loss of revenues with matching increases in operational costs to a city and its water utility.

Worldwide water losses are estimated at $14 billion a year, with at least $2 billion of this being lost in the US. Concurrently, the degradation of a water supply system can cause environmental degradation and structural damage while posing a potential health threat due to impurities entering the water distribution system. Not only do leaks reduce supply, they can impair the quality of the water itself.

Rarely does anything rapid or catastrophic happen. Occasionally, freezing water pipes may burst or a water main can be accidently damaged by construction activity or the sudden shifting and settling of surrounding earth. But most damage to water pipes (and the resultant loss of water) sneaks up on a utility, occurring incrementally and building up cumulatively over time. Aging water systems experience the most losses. All pipes and fixtures deteriorate and decay with time. The older the system, the more vulnerable it is. Corrosion and rust accumulation, differential settlement, the wearing away of seals and fixtures, dislocation of joints, vibratory damage, blockage due to clogging, and simple wear and tear on valves and meters are all factors that contribute to the slow and inevitable decay of a water supply system over time. And many large cities have water supply systems that date back more than a couple of centuries.

In the case of water supply systems, the first step in solving this problem isn’t admitting that it exists. The first step is finding where it occurs. Lack of monitoring can result in unaddressed problems accumulating to the point at which the integrity of the whole water distribution system can be called into question. And all of this can be prevented by vigilant monitoring of the system for water losses caused by this type of damage. If there was ever an instance in which an ounce of prevention was worth far more than a pound of cure, it is in the monitoring and auditing of water supply systems.

Prevention is the key, since modern monitoring systems can practically predict where the water losses can occur. This allows a system operator to focus his limited resources for maintenance and repair where they are most needed and cost-effective. This is also of great financial importance since over 30% of a water system’s operating budget can be devoted to maintenance. And maintenance, being labor intensive, is inherently expensive.

But the largest financial losses that occur within a water system are the opportunity costs associated with non-revenue water. Non-revenue water (which is not the same as unaccounted for water) is defined as water that is delivered by the water distribution system but never makes it to paying customers. Though there are legitimate non-revenue water losses (such as water used by fire fighters hooked up to a hydrant), it still does not provide revenue to the water utility even though it is an authorized water use.

Potential end-users never see leaked water since it has been lost to the system via physical leaks from bad joints and line breaks (though some non-revenue water is “lost” due to tampering with meters, theft, or poor record keeping by the water department). The rate of water loss is typically measured in terms of volume lost per length of pipeline in the system (liters per kilometer or gallons per mile). These loses will vary with location depending on the water head at a particular point in the system. The same leak near the source of the water supply may be under greater pressure than water traveling through pipes at the far end of the pipe system, and will therefore experience much greater water loss due to the higher applied pressure head.

WATER DISTRIBUTION SYSTEM OPERATION AND LOSSES

Water is carried throughout a city being served by a system of buried underground pipelines of various types and sizes. In addition to these pipes is the source of water (groundwater well fields, manmade reservoirs created by dams or dikes, natural lakes and ponds, etc.). Water from the source is pumped via extraction wellheads to a treatment facility that purifies the water for human use by removing impurities such as dirt and bacteria. In order to handle surges in demand, the purified water is usually pumped into elevated water tanks, which store the water for later use. These tanks are typically elevated so that they can gravity drain to most of the distribution system with sufficient elevation head to ensure proper pressure at the spigot.

The pipe system begins with a very large diameter central water main. This carries the water to a series of smaller branch pipelines, which, in turn, distribute the water to smaller diameter service pipes, which then connect up to the water consumers. Each pipe where a branching pipeline diverges from the main represents a node in the system and is represented by an appropriate pipe fixture (bends, valves, tees, wyes, flanges, etc.), and each node represents a potential failure and leakage point. Structurally, these are vulnerable because applied forces from overburden, ice buildup, vibration, and shifting soils get concentrated at these points. Furthermore, each fixture is connected with a joint that is usually weaker than the pipe it is connected to.

The pipes themselves are made from a variety of materials, with older pipes typically made from materials that are significantly different than newer pipes. The oldest cast iron water pipes have been replaced with flexible ductile iron pipes and steel pipes, which, in turn, are often replaced by polyvinyl chloride (PVC) pipes—though very large diameter water mains are still typically made from reinforced concrete pipes. PVC is popular because it is inexpensive, durable, and resistant to corrosion. The pipe sizes also vary considerably, from branch lines servicing homes as small as a half inch in diameter, to more than 16 inches in diameter for water mains.

LEAK DETECTION TECHNIQUES

A newly constructed water distribution system made with modern materials leaks very little at first. All piping systems wear out over time and develop revenue-stealing leaks. Each year, the problem gets worse and the water system operator must devote significant resources to leak detection operations. Leak detection is defined as “the systematic method of using listening equipment to survey the distribution system, identify leak sounds, and pinpoint the exact locations of hidden underground leaks.”

The technology changes with time, but the procedures remain the same. These methods can be direct or indirect, internal or external. Indirect methods rely on statistical analysis of flow data and pressure reading. Direct methods require active physical detection of leak locations. Internal methods measure the characteristics of the liquid flow (velocity, temperature, pressure), while external measures require sensors that listen for leaks outside the pipes. Though there are many advanced and expensive leak detection technologies used by industries (especially the oil and chemical industries) to detect leaks in process pipelines, most of these methods are not applicable to finding leaks in buried water distribution pipes.

Except in those rare cases in which leaks are actually visible on the surface (ponding and sink holes, structural damage, buckling pavement, etc.), water system operators are flying blind when it comes to detecting and locating leaks. Thus, they have to rely on acoustics for detection. Leaks give off audible noises and hisses as pressurized water escapes from the pipeline. The nature of these sounds varies with pipe material types and pipeline location. Metal pipes sound louder and are at higher frequencies than PVC. Sound also travels for greater distances along metal pipes (up to 1,000 feet) and less for PVC (less than 100 feet for large diameter PVC pipes). Like church organs, the diameter of the pipe affects the pitch with larger diameter pipes sounding at lower frequencies and smaller diameter pipes being higher pitched. Loose soils do not transmit sounds as well as tightly compacted soils, and a thick soil overburden can further muffle the noise of a leak. The presence of thick pavement and heavy vehicle traffic can make it even more difficult to get an exact reading.

The act of leak detection itself involves the use of a ground microphone as the technician walks slowly along the pipeline. The length, alignment, and depth of the pipeline should hopefully be determined from existing site surveys and pipeline system maps. As the technician moves, the signal will get stronger as he approaches the leak location and will then fade as he passes it. This method can usually locate the source of the leak within 3 to 4 feet, large enough to allow for a hole to be dug to expose the leaking pipe and allow for repairs.

PERFORMING LEAK AUDITS

The key to detecting and minimizing water losses are regularly scheduled audits (performed at least annually, which should include annual updates of the audit’s extent and scope) and a thorough analysis of the resultant data. During an audit there is an examination of both the accuracy and completeness of the water supplier’s records and data. These include billings, receipts, and meter readings. By collating this data geographically, water system operators can gauge the efficiency of the system’s distribution system. In doing so, they can identify potential locations of water loss along with estimated amounts at each leak point. Audits allow for updating of system information including the system’s master operating plan, maps of the distribution system, meter evaluations and upgrades, records organization and collation, along with manual examinations of fittings, valves, etc. Costs of audits vary with both the size of the distribution system and the depth of analysis, and are usually charged per mile of water main or pipeline. Audits can be performed by in-house staff or by hired consultants.

The simplest method of performing a water audit is to measure water distribution during off-peak hours (such as from 2 a.m. to 3 a.m.). If the amount of water distributed during these hours of low water usage shows a steady increase over time, it is indicative of significant water losses in the system. While this method is inexpensive and straightforward, it only provides an indication that there is a problem, not where the problem is located, the cause of the problem, or how to fix it. Even so, water utilities performing more detailed audits may find this to be a useful first step.

The initial steps in performing a water audit are to identify all the sources of water supply feeding the distribution system and quantify the amounts of water (measured in gallons per day) of each source. The summation of these numbers will give the total amount of water supplied by the system. The flow numbers should be checked against meter readings at each source to verify these quantities. Flow quantities should be adjusted to compensate for potential meter error.

Once these quantities have been identified, calculated, and verified, they can be checked against each metered water user. These are residents, businesses, industries, and rental dwellings that are authorized metered customers of the water system. A thorough examination of their records since the previous audit last year will indicate any changes that have occurred since then. In addition to authorized metered users, there are authorized unmetered users. These include fire fighting operations and training, extraction of water by tanker truck, community pools and recreation centers, landscaping operations for city parks and green spaces, flushing of clogged mains and storm drains, cleaning out sewers, street cleaning operations, and use by other government facilities.

Armed with this data and its geographical correlates, an operator can identify potential locations of water loss while estimating the amount lost at each leak location. There are a multitude of potential types of water losses: illegal water taps, broken and malfunctioning meters, leaking pipe fittings and fixtures, worn out valves, leaks from reservoirs, and tanks independent of leaks from the piping system. Poor record keeping, paperwork errors, and accounting mistakes may also account for lost water. But once the problem has been properly defined by the audit, the operator can plan corrective measures.

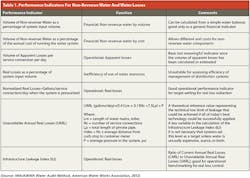

The International Water Association (IWA), in conjunction with the American Water Works Association (AWWA), has standardized the methods and terms used by water audits. This consistent methodology rationalizes the process and results in consistent performance indicators. The IWA and AWWA divides total system water supply into authorized consumption and water losses. Billed authorized consumption (revenue water) is what we normally think of as typical water supply distribution and usage. Unbilled authorized consumption includes those unmetered but acceptable activities described above. These, along with water losses, are classified together as non-revenue water. These losses include real physical losses from leaks and pipe failures as well as apparent losses from booking errors. The performance indicators of the IWA/AWWA method are calculated as shown in Table 1.

MAJOR COMPANIES IN THE INDUSTRY

An Israeli company, Aquarius Spectrum is a leading provider of leak detection solutions for all types of water networks. Since 2009, Aquarius Spectrum (a division of CK Hutchison Holdings Limited) has specialized in cloud technology solutions for monitoring municipal water distribution networks and detection of underground leaks from the earliest stages of their development (1.5-mm holes at 3 bars pressure) using both fixed and mobile acoustic sensors. The company’s comprehensive system can monitor every main, branch pipeline, and fixture of an entire water distribution network. As it does, it provides a complete, up-to-date graphical representation of the location, duration, flow data, and statistics of every point of failure and water loss. With this information, water system engineers and operators can make cost effective and timely decisions concerning their water systems operating, maintenance, replacement, and repair activities. This data optimizes both financial resources and minimizes water losses.

In addition to the fixed AQS-SYS system, Aquarius Spectrum provides a portable leak detection system, the iQuarius. Its capabilities include: leak mapping by automatic noise analysis and GPS positioning, leak pinpointing through correlation between pairs of sensors plus sensitive ground microphones, measuring and analyzing vibrations, performing high-resolution correlation, and reviewing the results of these readings. It connects to a smart phone via its own proprietary app, making it the first such system on the market. By utilizing either conventional, single-sensor samples, or advanced dual-sensor samples using correlation algorithms, the iQuarius provides highly accurate leak detection location capabilities. It can be used as either a standalone tool or in conjunction with their fixed AQS-SYS system. Like the AQS-SYS, the iQuarius utilizes a web interface and can incorporate maps of the water supply system.

ITRON successfully manages and minimizes non-revenue water losses associated with distribution leaks. According to their approach, the key to reducing these losses is to first know about them. The challenge lies in seeing the oftentimes-invisible issues. To do that, they listen by deploying a system of acoustic leak sensors. This gives a utility the ability to continuously listen to and monitor the health of its distribution system. Knowing when and where a leak is before it surfaces enables a utility to be proactive in the maintenance of its system. Being proactive empowers efficient and effective distribution system management, making it possible to decrease unnecessary loss, decrease the cost of repair, increase the availability of a resource, and ultimately, reduce non-revenue water losses.

Deploying acoustic leak sensors as part of an AMR or AMI system makes it possible for a utility to continuously monitor the health of a distribution system. In other words, ITRON’s technology makes it possible for a utility to audit its system 24 hours a day, seven days a week. The data that is gathered (as part of the same effort being employed to read the service territory’s water meters) is then presented in a number of different ways, including tablature and graphical. This makes it easy to identify possible leaks in the distribution system so they can be repaired in a timely manner. Several utilities have successfully reduced non-revenue water with ITRON’s leak detection solution: