In just 14 years, the United Nations estimates the world will only have 60% of the water resources it needs, if we do nothing different. Obvious solutions to water scarcity can include water reuse, wastewater reclamation, and conservation. But, what if we are just hitting the tip of the iceberg with these tactics?

Population growth, urbanization, industrialization, freshwater scarcity, and environmental pressures are converging, generating enormous performance imperatives as the industry strives to meet increasing demand with fewer resources. Because the water-energy nexus can act as a seesaw—where poor management or inefficiencies in one area can impact the sustainability of the other—addressing demands requires a multidisciplinary, applied science approach.

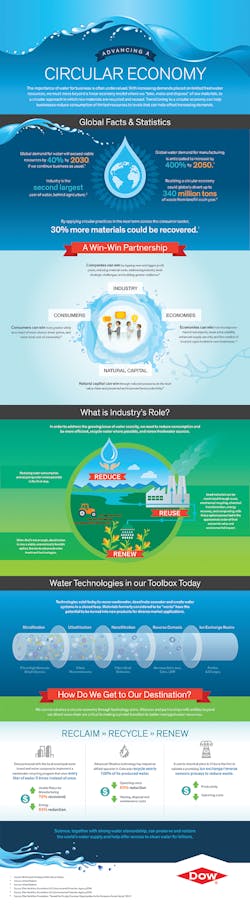

Industry’s role in moving toward a circular economy

The water-energy nexus makes emerging industry challenges complex and difficult for any single stakeholder to address, but it also broadens the solutions available in the toolbox. Opportunity can be found by applying an integrated approach that uses advanced water technologies across multiple industries, like oil and gas and microbial control. Taking a broader look at these adjacent industries enables us to think critically and creatively to solve for water and energy.

RECLAIMED WASTEWATER HELPS REDUCE STRAIN ON LOCAL SOURCES

Industries, municipalities, farms, and surrounding communities often face competition for freshwater resources to meet local demand. To help alleviate strain on freshwater assets, many facilities are turning to alternative sources by treating and utilizing reclaimed wastewater in operations.

Dow Water is leading by example and adopting water reuse technologies to reduce its freshwater intake at water-stressed sites. For example, the Camp de Tarragona petrochemical complex in Spain has minimized local freshwater stress by reclaiming municipal wastewater for industrial reuse. The facility uses a combination of extra fouling-resistant and low-energy membranes, which requires 33% less pressure than traditional technologies, which reduces overall energy and cost related to pumping. Dow’s ethylene cracker cooling tower at Camp de Tarragona is using up to 40% reclaimed water, reducing chemical use by 23% and reducing blowdown by 49%. Dow’s final target is to serve 90% of the complex’s water demand with reclaimed water.

Freeport, TX, is home to the largest integrated chemical manufacturing complex in the western Hemisphere. To help reduce waste, conserve freshwater resources, and save on costs, Dow collaborated with the City of Lake Jackson to divert the city’s treated wastewater effluent to Dow’s raw freshwater canal for operational use. By reusing the city’s wastewater for industrial operations, Dow is reducing freshwater use by over 1.3 billion gallons a year. The equivalent freshwater savings represented by this project could supply a community of approximately 30,000 people for one year.

In South Africa, the primary source for generating energy is coal, which represents more than 80% of the country’s energy supply. Facing limited local water resources, a coal mine implemented water reuse strategies, but also needed to manage the threat its wastewater posed to the environment. Finding conventional sand filters and traditional ultrafiltration technologies ineffective, the mine installed Dow ultrafiltration technology to pre-treat water before reverse osmosis to recover and reuse the wastewater. The treated wastewater is then fed to the local power station as make-up water. This system reduces operating costs and helps the mine avoid putting nearby water sources at risk.

Advanced treatment technology used in the Carlsbad Desalination Plant helps alleviate water scarcity in San Diego County.

ENERGY-EFFICIENT MEMBRANES UNLOCK NEW WATER SOURCES, LESS WASTE

Today, a key water management issue is balancing the connection between water and energy. Finding energy-efficient solutions to treat water is essential. Operators strive to produce required and regulated water quality, while also reducing energy consumption. The good news is that membrane technology has advanced and helped reduce the high-energy and cost burden associated with water purification.

In California, a state well known for its water stress and drought conditions, advanced reverse osmosis technology at the Carlsbad Desalination Plant is helping desalinate seawater to facilitate a locally controlled, drought-proof supply of drinking water. The plant is producing potable drinking water for nearly 112,000 households in San Diego County. Compared to the reverse osmosis technology available 10 years ago, the system (which uses DOW FILMTEC Reverse Osmosis Elements) requires 12% less energy to yield water of the same quality and quantity.

Ninety-miles north of the Carlsbad facility in Orange County, DOW FILMTEC Reverse Osmosis Elements are helping to treat reclaimed municipal wastewater from 850,000 residents for potable reuse. The technology has helped lower the facility’s energy use by 13% compared to pre-existing membranes, reduced operating costs, and in effect, lowered the entire carbon footprint of the facility.

ADVANCED TECHNOLOGY HELPS IMPROVE ENERGY AND WATER EFFICIENCY

Across industries, operators are faced with the constant challenge of improving water and energy efficiency. The biggest area of growth has come out of tapping new applications and advancing solutions that make it less energy intensive and more affordable. For example, we are seeing a growing trend in the mining industry, in which operators are looking to proven technologies from water and other markets, and are rethinking ways to cut cost and improve energy efficiencies throughout the mining and extraction process.

Oil and gas operators are finding opportunities by applying an integrated approach that uses not only advanced technologies for oil and gas, but options that stem from water and process applications. For example, BNN Energy helped its customer (an oilfield operator) reduce water sourcing costs and environmental impact by integrating TEQUATIC PLUS Filters into their system. The oilfield operator has since increased the volume of recycled produced water to almost 100% and expects to save about $2 per barrel of water, reducing operating costs by about 60% (Results may vary depending on specific operating conditions).

From a commercial market perspective, hospitals, power plants, schools, large manufacturing facilities, and other energy-intense facilities have been successful with the use of microbial control technologies that help cooling water system operate at exceptional capacity. Biofilms can build up in a system to cause scale and microbiologically induced corrosion, which can impact water flow and decrease energy efficiency. In small- to medium-sized closed loop cooling towers, advanced biocide technologies are enhancing cooling tower energy-efficiency and capacity by inhibiting corrosion-causing biofilms.

GAS TREATMENT SOLUTIONS MINIMIZE COST AND ENVIRONMENTAL IMPACT

The technologies available in our toolbox today.

The tightening of environmental regulations in many regions of the world intensifies the demand for cleaner gas solutions and efficient, cost-effective operations. For natural gas processing, these and other factors add up to a critical need to enhance output and minimize cost. High-temperature heat transfer fluids, like the DOWTHERM line, help reduce the piping and equipment size of operations compared to steam systems. Heat transfer fluids are used extensively in the Middle East and globally to move heat generated by equipment to process operations that require heat. Dow’s DOWTHERM G heat transfer fluid is enhancing Saudi Aramco’s Shaybah crude oil production site in the extreme-weather and water-scarce climate of Saudi Arabia.

Hot climates, like those in the Middle East, also have a strong need for cooling in gas treating. To address this, Dow researchers are currently developing a high-temperature, specialty gas treating solvent to prevent the need for water-cooling in hot climates. The solvent has the potential to save Middle Eastern gas plants and refineries approximately 30% in both capital and operating costs, while also minimizing their environmental impacts.

DRIVING AN INTEGRATED APPROACH EVEN FURTHER

As these examples show, we are not in need of new, disruptive technologies to help us to have adequate water and energy resources available in the future. We can leverage the technologies we already have in our toolbox today—reverse osmosis, nanofiltration, ultrafiltration, ion exchange, microbial control technology, and oil and gas solutions—to increase sustainable water and energy consumption.

A circular economy approach helps materials formerly considered waste—including wastewater and heat—to become new products for a range of applications. Advanced chemistry, engineering, and materials science capabilities have played a vital role in turning customer challenges into exceptional opportunities—whether it be enhancing production or enhancing efficiency resource consumption or emissions.

Dow’s global R&D facilities help foster innovation and science-based solutions to address needs in the communities it serves. For example, the regional research center at King Abdullah University of Science and Technology (KAUST) in Saudi Arabia is developing solutions to address the region’s distinct needs in water, energy, and infrastructure to build a stronger economy. The current expansion of the KAUST facility is just the latest in a series of collaborative initiatives to invest locally and develop solutions to increase water treatment efficiency by lowering energy consumption, decreasing operating costs, and reducing strain on resources.

As these examples demonstrate, human ingenuity is at the heart of solving water-energy challenges that improve economics and the environment for sustainability that is truly sustainable.

As the global population continues to grow and the world transitions to a sustainable, lower-carbon energy future, balancing the need for clean water and energy will continue to be a focus for all stakeholders across the value chain—municipalities, agriculture, manufacturing, oil, and gas, industrial and power, among others. We all have a role to play to help resource demand to be met tomorrow. It is important to start by investing in nature and one another today.