Water scarcity in the U.S. and around the globe is becoming a significant problem due to limited availability of freshwater resources and the high cost of transporting fresh water from distant sources to water demand areas. This situation has led to a renewed focus on developing seawater and brackish water as alternative sources of potable water. In addition, water infrastructure energy use and the carbon footprint of water consumption have both emerged as critical issues. Therefore, water and energy nexus implications are integral to the feasibility of developing seawater and brackish water.

Water quality in terms of salinity is best expressed by the concentration of total dissolved solids (TDS), the sum of all the minerals, metals, cations, and anions that can be dissolved in the water. Table 1 shows various categories of water and possible ranges of TDS concentration.

A high TDS concentration in water affects human health and causes other problems such as scaling in pipes and corrosion of piping and fixtures. The U.S. Environmental Protection Agency (USEPA) has set the Secondary Maximum Contaminant Level (SMCL) or aesthetic standard for TDS in potable water below 500 mg/L; in drinking water a TDS concentration of <200 mg/L is desirable. The goal of desalination is to treat high salinity water; the produced water should be acceptable for potable use and/or other intended uses. Modern desalination techniques include thermal (distillation) techniques and membrane filtration techniques, which are extensively reported in literature.

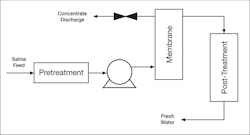

In the U.S., the dominant desalination technology is membrane filtration, which includes reverse osmosis (RO, see Fig. 1) and electrodialysis (ED)/electrodialysis reversal (EDR). In this article, critical issues of desalination are discussed, focusing on: energy use efficiency; the environmental impact of concentrate, which is a byproduct of desalination; and regulatory and permitting requirements and enforcement.

ENERGY USE EFFICIENCY

A desalination plant’s energy consumption depends on several factors including, but not limited to, desalination technique, TDS concentration and temperature of source water (feedwater), plant capacity, and the plant location with respect to the source water intake and the concentrate discharge. From a water-energy nexus perspective, three approaches—colocated plants, cogeneration plants and hybrid plants—provide opportunities for energy use efficiency in desalination plants.

Colocated Plants: In this approach, a desalination plant is colocated with a power plant in a coastal area where the power plant draws seawater to be used as cooling water. The desalination plant uses heated seawater from the power plant’s cooling water loop as feedwater, which requires less energy for desalination. The desalination plant discharges its high-TDS concentrate byproduct into the power plant’s cooling water outflow, thus providing a way to dilute the concentrate before it is discharged back into the ocean.

Because the desalination plant “piggybacks” on the power plant cooling water loop, it can reduce its energy consumption. As an example, the Tampa Bay Seawater RO Desalination Facility is colocated with Tampa Electric’s (TECO) Big Bend Power Station, which withdraws and discharges up to 1.4 billion gallons per day of seawater from Tampa Bay, using it as cooling water for the power plant. The Tampa Bay Seawater Desalination plant “catches” up to 44 million gallons per day of that warm seawater for desalination. The diluted concentrate is discharged to Tampa Bay (see Fig. 2).

Cogeneration Plants: In this approach, a typical power plant produces high pressure/temperature steam, which is normally expelled from the power plant as waste. A cogeneration plant uses this steam as an additional energy source during the desalination process in order to reduce fossil fuel use.

The power plant gains extra revenue by selling the waste steam to the desalination plant, while the desalination plant avoids having to pay for the construction and operation of its own energy source.

Hybrid Plants: Hybrid plants use a combination of treatment technologies, which enables the plant to reuse energy and optimize plant performance. As an example, the Cape Hatteras desalination plant in North Carolina operates a hybrid RO/ion exchange plant using brackish water. The plant withdraws water from two separate wells; the high salinity water from Well 1 is processed by the RO process, and the high organic content water from Well 2 is processed by the ion exchange process. The treated water from the RO and ion exchange processes are blended as the final product water. This plant has also incorporated an energy recovery turbine into the RO treatment process.

RENEWABLE ENERGY USE

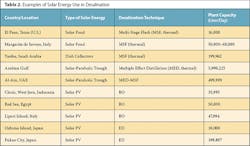

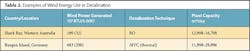

The potential use of renewable energy for desalination has been reported since the mid-1990s. In the U.S., a few conventional water treatment plants, such as several drinking water treatment plants in Massachusetts, have integrated solar PV for water treatment.1 Tables 2 and 3 show a few examples of desalination plants around the world using various types of solar energy and wind energy for desalination.

ENVIRONMENTAL IMPACTS

Risks associated with the construction of desalination plants include construction of water intake infrastructure and the network of pipes transporting the feedwater to the plant, which may impact environmentally sensitive areas. However, concentrate (reject salt) still remains the most critical environmental problem, which also affects the cost-effectiveness of desalination. RO plants produce high TDS concentrates (>65,000 mg/L) that may also contain some toxic chemicals used during feedwater pretreatment and post-treatment (cleaning) processes. Selection of a concentrate management option depends on several factors: concentrate volume and quality, the location of the desalination plant, and the pertinent environmental regulations (which is discussed later). Examples of concentrate management practices include:

- Surface water disposal. Disposing of concentrate in tidal rivers and streams, coastal waters such as oceans, estuaries, and bays adjacent to or near the plant is the most common method of concentrate disposal. Environmental concerns include adverse impact on the receiving waters’ ecosystems, and the long-term effect on the water quality of coastal aquifers.

- Submerged disposal. Concentrate is transported away from the desalination plant via underwater pipes to an estuarine and/or ocean location. Environmental concerns include potential impact of sinking concentrate on benthic marine organisms living on the sea bottom.

- Deep well injection. Concentrate is directly injected into deep groundwater aquifers. This practice is site specific due to geologic condition and potential impact on drinking water sources.

- Evaporation ponds. Constructed ponds with liners are used to allow water evaporation from the concentrate while the remaining salts accumulate in the pond bottom. Evaporation ponds are a cost-effective option in areas of warm climates and high evaporation rates. However, they are moderately land-intensive and also cause significant loss of the basic water resource through evaporation.

- Land application. This method uses spray irrigation, infiltration trenches and percolation ponds. Land application provides an opportunity for a beneficial use of concentrate. For example, concentrate can be used to irrigate salt-tolerant crops and grasses such as those used on golf courses. The feasibility of land application depends on the local climate, vegetation tolerance to salinity, the availability of land, and the location of the groundwater table.

- Integration with a wastewater treatment plant. Options here include concentrate discharge to the front of the wastewater treatment plant or to the end of the wastewater treatment plant. However, discharge to the front of a wastewater treatment plant is not recommended because conventional wastewater treatment plants do not remove TDS and concentrate TDS level can have a significant impact on the biological treatment process. Concentrate disposal to the end of a wastewater treatment plant results in diluted concentrate due to it mixing with treated wastewater. It's important to note that, despite dilution, this practice may adversely impact receiving water. Also, there will be additional cost for constructing a separate pipeline (and perhaps using a pump) to carry the concentrate to the wastewater treatment plant.

- Brine concentrators. The brine concentrator process uses heat exchangers, deaerators, and vapor compression to convert liquid concentrate into slurry form. Using a brine concentrator, 95 percent of the water can be recovered as a high-purity distillate with less than 10 mg/L of TDS concentration. The remaining 5 percent of concentrated slurry can be reduced to dry solids in a crystallizer to create dry, solid cake, which is easy to handle for land disposal. As a cautionary note, some chemicals may be present in the dry solid.

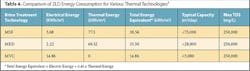

- Zero liquid discharge (ZLD). The ZLD technique originally developed for solid waste management is promoted as a new technology for concentrate management. The ZLD technique uses an evaporation process to convert a liquid concentrate (brine) into a dry solid that can then be utilized for beneficial purposes. As a cautionary note, some chemicals may be present in the dry solid. Furthermore, the ZLD process is a high-energy-cost technique. Using thermal technologies may facilitate more cost-effective ZLD application for concentrate management. Table 4 shows the energy consumption required to achieve ZLD using existing thermal technologies (MSF, MED, mechanical vapor compression [MVC]).

FEDERAL REGULATORY REQUIREMENTS & PERMITTING

Major regulatory and permitting issues that relate to planning and implementing desalination plants include developing the saline water source, and discharge and management of concentrate. Federal laws that are pertinent to desalination are briefly described below.

The Clean Water Act: The CWA provides the statutory basis for the National Pollutant Discharge Elimination System (NPDES) permit program and the basic structure for regulating the discharge of pollutants from point sources to waters of the United States. Section 402 requires the USEPA to develop and implement the NPDES program.

Sections 316(a) and 316(b) of the WA authorize the USEPA to address issues related to discharging heated water into receiving waters. The regulation applies to desalination, particularly if the desalination plant is colocated with a power plant. Section 404 of the CWA authorizes the United States Army Corps of Engineers (USACE) to issue permits for disposal of dredge or fill materials to U.S. navigable waters. If a desalination plant intends to construct, excavate, or fill navigable waters of the U.S., a permit must be obtained from the USACE to authorize such an action.

The Safe Drinking Water Act:

The SDWA establishes a federal program to monitor and increase the safety of the nation’s drinking water supply. The SDWA authorizes the USEPA to

set and implement health-based standards to protect against both naturally occurring and man-made contaminants in drinking water. The SDWA

applies to desalination plants that treat brackish or seawater for public consumption and to desalination plants that inject or discharge the brine into a source of water that may be used for public consumption.

The Resource Conservation and Recovery Act: The RCRA applies to the disposal of the concentrate and brine discharge to receiving waters.

The Superfund Amendments and Reauthorization Act: The SARA applies to discharge from desalination plants if the discharge contains any substances found on the Extremely Hazardous Substances list described in Section 313 of SARA.

The Endangered Species Act: The U.S. Fish and Wildlife Service (USFWS) maintains the list of endangered and threatened species. The USFWS can require a desalination plant to prepare a formal biological opinion if the plant operation may impact an endangered species.

The Water Desalination Act: The Act authorizes the Secretary of Interior and the U.S. Bureau of Reclamation to award grants and to enter contracts through the Desalination and Water Purification Research and Development (DWPR) Program for desalination research, development, and demonstration projects.

STATE LEVEL REGULATIONS & PERMITTING

A few states have regulations and/or permitting requirements that relate to desalination. Requirements in four states (California, Texas, Florida and Virginia) discussed in this article can be considered representative of desalination regulation/permitting requirements in the U.S.

California Regulations: California Desalination Planning Handbook provides the most comprehensive guidelines and a wealth of information about benefits of and frameworks for planning desalination projects. Chapter 6 of the handbook describes regulations and permitting requirements. The California Environmental Quality Act (CEQA) of 2003 (amended in 2004) contains provisions for desalination plant permitting. The brine discharge from a desalination plant is regulated through the NPDES, which is enforced by Regional Water Quality Control Boards. The California Coastal Act (CCA) includes policies that specifically address desalination. The CCA is applied to desalination on the following issues: environmental policies, growth inducement and coastal-dependent versus coastal-related development, and feasibility of the maintenance of coastal areas.

Texas Regulations: In 2002, the Texas Water Development Board (TWDB) established the Seawater Desalination Initiative to develop a proposal for building a large-scale seawater desalination plant. In 2003, the 78th Texas Legislature passed House Bill 1370 directing the TWDB to undertake or participate in research and demonstration projects to advance seawater desalination. In 2015, the 84th Texas Legislature passed House Bill 2031 relating to the diversion, treatment, and use of seawater. The legislature also passed House Bill 4097 relating to the use of seawater desalination for industrial purposes. The overall goal of the legislation was to streamline and expedite the regulatory process associated with seawater desalination. In response, the Texas Commission on Environmental Quality created a new permitting process and published instructions for completing the marine seawater desalination permit application, and made rules effective on December 8, 2016.

Florida Regulations: The Florida Department of Environmental Protection (FDEP) holds the jurisdiction over the regulation of desalination plants. Florida State Code Section 62 addresses the following issues related to desalination plants: permitting process (Section 62-4); brine and concentrate discharge to surface waters (Section 62-4.200); discharge quality and toxicity requirements (Section 62-4.244); guidelines for the testing of receiving waters (Section 62-4.246); surface waters and water quality standards (Sections 62-301 and 62-302); groundwater classes, standards, exemptions (Section 62-520); underground injection control (Section 62-528); drinking water standards, monitoring, and reporting (Section 62-550); reclaimed water and land application (Section 62-610); water-quality-based effluent limitations (Section 62-650); and industrial wastewater facilities (Section 62-660).

Virginia Regulations: A few brackish water (groundwater) desalination plants are operating in Virginia. Developing brackish groundwater in Virginia follows the established permitting regulations for developing aquifers in Virginia, defined in Section 62.1–256 of the Ground Water Management Act of 1992, which allows the Virginia Department of Environmental Quality (DEQ) to review the permit applications for the proposed withdrawals. The authorization to discharge concentrate is issued under the Virginia Pollutant Discharge Elimination System (VPDES) in compliance with the provisions of the Clean Water Act and NPDES. The permit may include requirements for special conditions such as discharge into nutrient-enriched waters, compliance with the toxic management program (biological monitoring of receiving waters), and a toxicity reduction evaluation plan. Commonwealth of Virginia ownership of submerged lands extends offshore to the 3-mile limit and includes all the beds of the Chesapeake Bay and tributaries. All Virginia laws for water use and concentrate disposal apply to this 3-mile limit.

CONCLUDING REMARKS

Abundant seawater and brackish water sources and fast-developing desalination techniques and research will provide significant opportunities to address current and future water scarcity problems. This article provides a brief introduction of critical issues of desalination including water-energy nexus, concentrate management, and regulatory/permit requirements. It’s also expected that evolving renewable technologies will facilitate the development of environmentally friendly and economically sustainable desalination plants in urban areas as well as smaller coastal communities.

REFERENCES

1. Massachusetts Energy Management Pilot Program for Drinking Water and Wastewater Case Study, EPA-832-F-09-014, U.S. Environmental Protection Agency, Washington, D.C., 2009.

2. "World's First Wave-Powered Desalination Plant Now Operational in Perth," ENGINEERS Australia news release, Oct. 28, 2015.

3. C. Charisiadis, "Brine Zero Liquid Discharge (ZLD) Fundamentals and Design," LENNTECH research report, 2018.