Polyurea Coatings Win Place in Water, Wastewater Facilities

By Tony Ippoliti

Waiting for paint to dry is not the best use of anyone's time. When upgrades are made to critical process operations, it's paramount to return equipment to service as quickly as possible. Reducing downtime typically minimizes both the inconveniences and the costs associated with maintenance painting.

When protective coatings are part of maintenance for a municipal water or wastewater treatment plant, the choice of coating used has a tremendous bearing on the amount of time required to complete the project. New coating formulations featuring faster dry times and other advantages can help to speed projects to completion and provide better long-term results.

One example is 100 percent pure polyurea coatings technology. Polyurea coatings have been used by the pharmaceutical and food and beverage industries, but only recently has an advance in coatings technology made possible 100 percent pure polyurea coatings that are approved by Underwriters Laboratories to the ANSI-NSF 61 Standard, expanding the potential uses for this coating by the water industry.

Fast Cure Times

Polyurea coatings are designed to create highly elastic waterproof coating and lining systems that are resistant to chemicals and abrasion. These fast cure, no VOC, no odor coatings are suitable for use in a broad range of industries because they offer ultra-high film build and dry in as little as 30 seconds. When coated with polyurea systems, substrates such as concrete and steel can be submerged, buried, or driven upon in just minutes. In contrast, traditional and even fast-cure epoxies can take a week to 10 days to completely cure.

Because of their elasticity, polyurea coatings are ideal for substrates such as concrete, which tends to crack. As an elastomer, these coatings have the ability to stretch and bridge gaps up to 1/8 inch. Due to this flexibility, polyurea coatings are not limited by extremes of temperature, while rigid coatings tend to crack as the substrate expands or contracts under these conditions

Another advantage of polyurea coatings is that they can be applied from 10 mils to 125 mils in one coat. Because only a single coat of this high build material is required, labor and rental costs for scaffolding and other equipment can be reduced. As a result, the costs associated with application are reduced.

Polyurea coatings also offer excellent adhesion. They are regularly tested at up to 2000 psi, compared with conventional epoxy coatings at 600 to 800 psi. Aliphatic polyurea coatings have exceptional UV light resistance, so they will withstand weathering and exposure to sunlight when applied to exterior surfaces.

Application and Uses

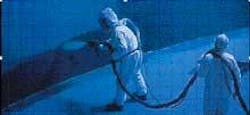

Because polyurea coatings provide an alternative to traditional systems, there has been an increase in the specification and use of these coatings. It is important for specifiers to recognize that only qualified applicators who have invested in the proper equipment and training should apply polyurea coatings.

The coatings have many uses for water industry applications. They are ideal linings for immersed surfaces and will resist hydrogen sulfide. They are also recommended for lining large diameter pipes, clear wells and filter beds. Polyurea coatings are also suitable for use in many wastewater processes and can be used to protect wet wells, lift stations and digesters.

Because the coatings can be cured under cold and hot conditions (from -20° F to above 350° F, and at high humidity), they can be applied throughout the year. This advantage recently led a consulting firm to specify a polyurea system for the digesters at a wastewater facility in Canada, since the material could be applied during frigid temperatures. The plant owner cited shorter installation time, faster cure time, elastomeric properties, resistance to H2S (hydrogen sulfide) and reduced heating costs as examples of what was gained by using the system.

In another instance, a polyurea coating was selected for the interior of an anaerobic digester, part of a multimillion-dollar renovation of a water pollution control facility (WPCF) in the Midwest. Work on the digester will involve removing the current floating roof, replacing it with a fixed concrete roof, and the addition of a center shaft and mechanical mixer.

The polyurea coating will be applied at 60 mils. It will withstand the current mesophyllic operating temperature range of 98° F to 100° F and can meet future operating temperatures of 130∞F to 140° F. If the facility should decide to process in the thermophyllic range in the future, the coating system will be able to handle the increased temperatures as well, with no additional cost or disruption of operations.

An example of polyurea coatings is EnviroLastic® AR 520 PW from the Sherwin-Williams Co. This 100 percent polyurea coating is USDA acceptable and UL approved to the ANSI-NSF 61 Standard. It is specifically designed for use in potable water storage tanks of 50 gallons or greater.

AR 520 PW polyurea contains no solvent and is virtually odorless. The coating is part of the ExpressTech™ family of Sherwin-Williams coatings engineered to improve end-user productivity by saving facilities owners and coatings applicators time and money on coating jobs.

To become an EnviroLastic® certified applicator, individual crew members must complete a 40-hour training class using specialized spray equipment. Certified contractors must be willing to invest their time and up to $45,000 to purchase the trailer-mounted equipment that proportions and heats the coating's two components as it is being applied.

After the polyurea coating is applied, it cures in a matter of minutes and can be disinfected in accordance with the American Water Works Association C652 Standard. As it cures, polyurea forms a highly impervious, abrasion-resistant, flexible lining system with excellent adhesion. The curing and disinfecting processes take no more than a few hours, so that a tank can be filled with water and placed back in service within hours if needed.

About the Author: Tony Ippoliti is a Senior Corrosion Specialist with The Sherwin-Williams Company. For more information on EnviroLastic® Polyurea, go to www.envirolastic.com.