Parallel Pumps: Reliability & Efficiency Issues

By Allan R. Budris

Parallel pump installations, where two or more pumps take suction from a common manifold and discharge into a common header, are very common in many industries, including the Municipal Water and Wastewater markets. Pumps are operated in parallel as a means of flow control and for emergency back up (installed spare). However, if the pumps are not properly selected for parallel operation, or operated in the most optimum combinations, pump reliability and overall system energy efficiency can be compromised. Operating the wrong pumps in parallel can even cause one of the pumps to operate at shut off, resulting in over heating and failure.

null

null

Parallel Pump Operation

When pumps run in parallel they operate against the same discharge head. The combination pump head-capacity curve is, therefore, determined by adding the respective flow rates of each pump, at a series of specific head values. This is demonstrated in Figure 1, where, at a head value of 240 feet, the flow generated by pump “A” at this head (320 gpm) is added to the capacity of pump “B” at this head (640 gpm) to create the combination H-Q pump curve (960 gpm @ 240 ft).

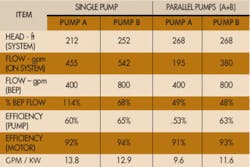

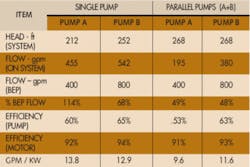

The head (and therefore flow) that each of the parallel pumps will operate at in a given system is then determined by the intersection between the system head-capacity curve with this “pump combination head-capacity curve”. In Figure 1, the system and pump combination (pump A + B) H-Q curves intersect at 575 gpm, at a head of 268 feet. The contribution of each of the pumps at 268 feet, are: pump A operating at 195 gpm and pump B operating at 380 gpm. This compares with 455 gpm when only pump A operates on this system, or 542 gpm when only pump B operates on the system (see Table 1). As can be seen, each of the pumps is forced to operate at relatively low flow rates. These lower flow rates can result in higher energy costs (because the individual pumps are operating at lower efficiencies and higher heads at these low flow rates), and reduced pump reliability (also due to the low flow rates - see December 2007 column). In this example, pump A has a best efficiency point (bep) of 400 gpm and pump B has a bep twice as high (800 gpm). However, very little is gained (+6%) by operating both of these pumps in parallel, while the energy effectiveness (gpm/kW) is reduced by 30% and 10% respectfully.

null

null

Energy Effectiveness

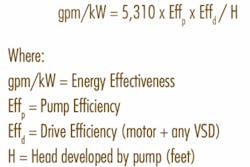

Pump Selection for parallel pump installations is key to minimizing energy costs. However, many parallel pump systems aren’t operated in the most energy efficient manner or combination. A new more optimum pump selection and operating plan can, therefore, provide substantial cost savings opportunities. The way to achieve the optimum parallel pump selection is to calculate the Energy Effectiveness (gpm/kW) of each pump and then select the single pump or pump combination that yields the highest Energy Effectiveness. The Energy Effectiveness of a pump over its flow range can be determined from the following equation:

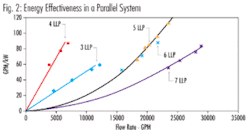

Figure 2 shows the results of using the above formula on a real world installation with five different high specific speed pumps operated in parallel, handling drinking water. As can be seen, the energy effectiveness of each pump increases with flow rate (for constant speed pumps), and is lower for the larger pumps, at a given flow rate. So in order to make the optimum Energy Effective selection for a parallel pump installation, the following guidelines should be followed.

- Calculate the gpm/kW vs. Flow Rate curve for each pump and combination.

- Operate the minimum number of pumps for any required system flow condition.

- Select the highest Energy Effectiveness (normally lowest head/capacity) pumps for any flow requirement.

See reference 2 for more details on how to use Energy Effectiveness to optimize pump selection.

Reliability Issues

Besides the reduced energy effectiveness and reliability from low flow parallel operation, as discussed above, there is another reliability issue with parallel operation using dissimilar pumps, which can be observed in Figure 3. As mentioned above, pumps operate at the same head when they operate in parallel. However, if the system were to push the combined pump flow rate below 1500 m3/hr in Figure 3, the head would be increased above 45 meters. This would push pump A to shut-off, which could cause the pump to over heat and fail. Below a flow rate of 500 m3/hr, pump B would also be pushed to shut-off.

When dissimilar pumps are operated in parallel, care must be taken to avoid operation that pushes any pump below its minimum allowable flow rate.

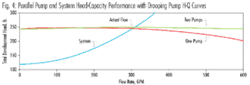

Finally, there is another issue to be considered when selecting pumps to operated in parallel, and that is the shape of the pump head–capacity curve. If the pump H-Q curve droops (the head drops) as the flow is reduced towards shut-off, zero flow (see Figure 4), a second identical pump may not be able to come on line, and could, therefore, run at shut-off, over heat, and possibly fail. In the real world case shown in Figure 4 the system would cause one pump to operate at 242 feet and 300 gpm. This head is also the shut-off head for the other identical pump. So that is where the second pump would operate. Even if the pump were to come on line, it would only increase the system flow rate by 5 gpm.

Pumps with head-capacity curves that droop towards shut-off, or have a dip at a higher flow rate which has more then one flow condition for a given head, should not be operated in parallel.

References:

“Pump User’s Handbook – Life Extension”, by Heinz P. Bloch & Allan R. Budris, 2nd Edition, 2006, The Fairmont Press, Inc.

“Parallel Pumps: Reduce Energy Costs Without Breaking the Budget”, Opflow, February 2008, Allan R. Budris, P.E.

“Optimizing Pumping Systems: A Guide for Improved Energy Efficiency, Reliability & Profitability”, Pump Systems Matter and Hydraulic Institute, 2008, Allan R. Budris, P.E. (contributing Author). WW

About the Authors:

Allan R. Budris, P.E., is an independent consulting engineer who specializes in training, failure analysis, troubleshooting, reliability, efficiency audits and litigation support on pumps and pumping systems. With offices in Washington, NJ, he can be contacted via e-mail at [email protected].

Circle No. 210 on Reader Service Card