Chemical Feed Scales Gaining Popularity

For years, weighing systems have been widely accepted as the standard for tracking chemical use in gas chlorination systems. Today though, weighing systems are showing up in all types of chemical feed applications. The popularity of weight-based monitoring devices is growing as operators recognize the unique advantages of a scale over other level measuring devices.

Applications for dry or liquid feed systems can range from a 15 gallon fluoride drum to a 200,000 lb lime silo. Continued gains in technology have allowed scale manufacturers to morph their products into more than just inventory control devices. New systems often provide advanced features such as chemical feed rate data and daily usage information.

As chemicals get more expensive and operating budgets get tighter, it becomes very important to accurately verify incoming chemical deliveries and track remaining inventories. With the continued development of the strain gauge load cell and new advances in instrumentation, overall accuracies of 1 part in 3000 (including temperature gradients) and stable resolutions of 1 part in 10,000 can typically be achieved.

Non-Contacting

Weight based systems do not enter the tank itself (non-intrusive) and do not come into contact with the chemicals (non-contacting), which helps improve system durable and reliability. Weight based systems also operate independent of material compatibility, specific gravity, temperature, conductivity, corrosiveness and viscosity. Simply put…weight is weight.

If your chemical is delivered in carboys, 55 gallon drums, IBC totes or cylinders, a weight based system requires simply that the operator place the container on the weighing device. That’s it! This eliminates the labor and exposure to hazardous chemicals that an intrusive level sensor requires each time new chemical is delivered.

Feed Rate Verification

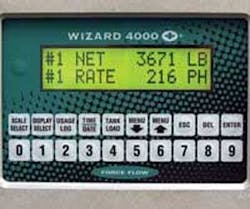

Simply because a metering pump is stroking or a dry feeder is turning does not necessarily mean that you are feeding chemicals to your water stream. Vapor locked hypochlorite pumps and “rat holing” in dry feeders has fooled the most savvy of operators. Because of the sensitivity and resolution that a weight based chemical monitoring system has, some systems integrate a loss-in-weight feed rate function that can be used to verify low or high feed conditions.

Feed rate is determined by sampling how much the chemical weight has decreased over a period of time. Depending on the feed rate and tank size, this sample or update period can be as short as one minute making the feed rate function near real-time.

To verify proper daily chemical dosages, most states now require reporting of chemical addition to public water supplies. Among these are The 10 States Standards, Massachusetts DEP and Maine DHS. Many of these regulations and recommendations are now specifically requiring weighing systems due to their accuracy, reliability and ease of use. Some manufacturers have integrated data logging devices into their instrumentation to further simplify the reporting. WW

About the author: Mark Nelson is an application engineer for Force Flow in Concord, CA. He has been designing weighing systems for municipal chemical feed for over 20 years and can be contacted at [email protected].

Circle No. 293 on Reader Service Card