New Larger Membrane Element Reduces Costs, System Size

By Antonia von Gottberg and Tim Pond

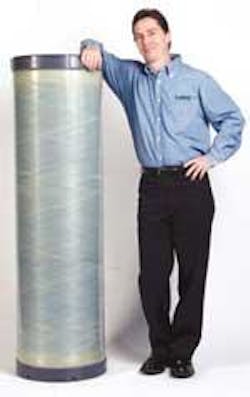

As the size of water treatment plants has increased, there has been much interest in large diameter RO (reverse osmosis) and NF (nanofiltration) elements. Recently, Koch Membrane Systems (KMS) introduced the world's largest spiral wound element, the MegaMagnum(r) element.

The element is 18 inches in diameter by 61 inches in length. Because of its size, in a typical system the element requires fewer connections and fittings, fewer seals and a reduced footprint.

From the beginning of the development program at KMS, it was clear that large plants would benefit from larger elements due to the economies of scale. However, as the program progressed, it became evident that smaller RO and NF plants could benefit as well. Smaller plants would be significantly more compact, which would reduce the system footprint and could result in a significant savings in building and civil costs. To make these benefits available to all customers, a line of compact, standardized RO and NF systems using the MegaMagnum element has been developed for small to medium capacities.

System Capacities

The pre-engineered systems can treat from one-half to two million gallons per day (MGD) of water. The systems are based on multiples of a 2:1 array, and are designed with the flexibility to operate over a range of fluxes and water recoveries. The standard package will be appropriate for a variety of applications. Typical applications for MegaMagnum systems include production of potable water from brackish water sources, softening, organics removal, removal of inorganic contaminants such as nitrates, and reuse of municipal and industrial effluent.

System Features

The skid-mounted systems are designed to fit into shipping containers for easy shipping and quick installation and start-up. Smaller systems fit on one skid, and larger systems are split into a vessel rack and a hydraulic skid.

The pressure vessels supplied with the standard systems are designed, manufactured and tested to ASME pressure vessel code section X with a pressure rating of 300 psig at 120

The systems contain five spiral wound RO or NF elements per pressure vessel. The elements use Fluid Systems(r) TFC(r) membranes, including High Rejection (HR), Ultra Low Pressure (ULP), Softening (S) and Selective Rejection (SR) membranes. The membranes are packaged as MegaMagnum elements.

The standard hydraulic system includes industrial grade pumps, valves, piping and instrumentation required for proper system operation. As part of the standard package, the high pressure feed pump is controlled by a variable frequency drive (VFD) to ensure operation over a wide range of operating conditions. Options include an interstage booster pump and a raw water feed pump. Cartridge filters are included, with N+1 on-line spare capacity to allow for change outs while the system is running.

The system includes a programmable logic controller (PLC) and a multifunctional, color touch screen human-machine interface (HMI). Data trending and Ethernet interface for remote access are part of the standard system package. The instruments needed to commission, operate, monitor and troubleshoot an RO system are also part of the standard package. These instruments include magnetic-type flowmeters on the permeate and concentrate streams, a feed pressure transmitter, first and second stage differential pressure transmitters and conductivity measurement for the feed, permeate and concentrate streams.

System Benefits

The MegaMagnum Systems have fewer vessels, elements, and connections than a typical 8-inch RO system. A typical 500,000 gpd system would need three MegaMagnum vessels with five elements per vessel compared to an 8-inch system that would require 16 vessels with seven elements per vessel. Using the larger elements reduces the number of permeate O-rings by a factor of almost 15, and the number of brine seals by more than a factor of six. This reduction in O-rings and brine seals helps reduce the chances of a seal leak and increases the on-line factor. Additionally, the number of high and low pressure piping connections is significantly reduced. For a packaged system, the floor space needed for the hydraulic skid would be the same for an 8-inch system; however, there is a savings in floor space on the vessel rack portion of the system.

Koch offers the systems in a pre-engineered, standard design with all the features needed to operate an RO plant. Several options are available to customize a system for a specific application or customer requirements.

Demonstration Unit

Piloting has been performed at several municipal sites, including the City of Scottsdale, AZ, and Metropolitan Water District of Southern California (MWD). The pilot studies used large elements to compare performance to standard 8-inch elements. The performance data verified that the larger elements operate at the same flux and pressure and produce the same water quality at the same fouling rate as 8-inch elements.

After piloting, MWD performed a preliminary cost analysis that showed a capital cost reduction of approximately 24% could be achieved by using larger diameter elements. Based on results from the single element pilots, MWD has decided to procure a demonstration unit.

About the Authors:

Antonia von Gottberg is Director of Municipal Water Technology at Koch Membrane Systems. von Gottberg has a Master of Science in Chemical Engineering Practice from MIT, and a Master of Arts in Engineering Science from Cambridge University, plus over 12 years experience in water treatment using a variety of membrane technologies. She may be contacted at [email protected]. Tim Pond is a Project Manager at Koch Membrane Systems. He has a Bachelor of Science in Chemical Engineering from Worcester Polytecnic Institute and has over 21 years experience in the water industry designing membrane systems.