Constant Wet Well Level Control Saves Cost and Energy

By James B. Rishel

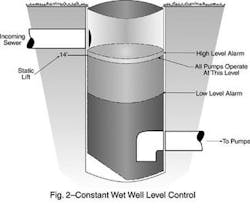

Constant wet well level control in variable speed, sewage lift stations saves first cost and energy. The traditional pump-down control, which depends on reduced levels in the wet well, increases the static lift and, therefore, the first cost and energy consumption. Also, the pump-down control may not operate the pumps at their most efficient speeds.

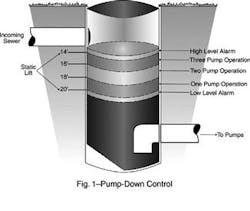

Two figures are needed to illustrate the difference between these two methods of control. Figure 1 describes a typical wet well with pump-down control while Figure 2 provides the operation of constant wet well control. The amount of pump-down, the distance between the highest and lowest operating levels, can vary substantially from one station to another. Smaller wet wells may operate with three or four feet while larger stations may have as much as 10 feet difference between the two levels. Figure 1 indicates a pump-down of six feet for a station with a capacity of 18 mgd (12,500 gpm).

First Cost

There are two specific first costs that are reduced by constant wet well control: wet well cost and pump cost. Wet well cost will be described first by using Hydraulic Institute's trench type wet well for sewage lift stations. This is described by Figure 9.8.13 in their American National Standard for Pump Intake Design, ANSI/HI 9.8-1998, page 16. The minimum submergence dimension, S, that is shown in this figure will not be calculated since the requirement for a minimum entrance velocity of 1 fps will result in a much higher sump level.

Savings in Wet Well Construction

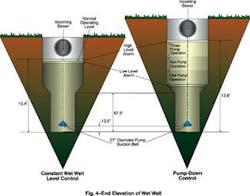

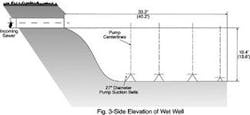

Figures 3 and 4 describe the configuration of an open trench type wet well for a sewage lift station with a maximum flow of 18 MGD and three operating pumps with a standby pump. Figure 3 is a side elevation providing the length of the station for constant wet well control and for pump-down control, the latter dimensions being shown in parenthesis. Figure 4 is an end elevation describing the differences in elevation for the two types of control.

The principal savings in the wet well construction achieved by using constant wet well control will be in the length and depth of the wet well. Using four sewage pumps with a capacity each of 4,170 gpm and 27" suction bells, the dimensions would be as shown in Figures 3 and 4.

Comparing the two figures, the station depth for constant wet well control will be 9.8 ft. below the invert of the incoming sewer while the pump-down control will require 13.6 ft. depth below the invert. Likewise, the overall length of the station for the constant wet well will be 33.2 ft. compared to 40.2 ft. for the pump-down control. Obviously, the actual cost difference between the two wet wells will be determined by local conditions, such as rock or unstable subsurface.

Pump Cost Savings

The savings in first cost for the pumps will be due to the possibility of smaller motors and variable speed drives, as well as shorter pump columns for vertical type pumps. The pump-down control results in 38 ft. pump head, and at 4,170 gpm it will require a 50 hp motor with an energy consumption of 37.8 kW. The constant wet well control results in 32 ft. pump head, and at 4,170 gpm, will require a 40 hp motor with an energy consumption of 31.8 kW.

Other pump cost savings will be contingent upon the type of pump used. The open trench type wet well is ideal for vertical pumps. They can be equipped with above or below base discharges. With this type of pump, there would be a reduction of 6 ft. in the length of the column assembly when using the constant wet well control.

Energy Savings

Energy savings can be realized with constant wet well control as indicated above where an energy savings of over 15% was achieved in this example. An added savings can be made using available software for programming multiple pumps. This includes kW input and adaptive control that monitor the actual pump energy consumption and program the pumps to achieve minimum energy consumption at all station flows from minimum to maximum.

A plan for programming pumps with kW input can demonstrate the use of adaptive control to adjust the pump start-stop points with the actual changes in kW input as the pumps are added and subtracted. This is typical of the analysis that can be made for a new or existing lift station.

The actual energy consumption is computed for each number of pumps that could be in operation. For a four-pump station, the energy consumption would be computed for one, two, three and four pumps running. From this, the theoretical transition points would be determined for one to two, two to three, and three to four pumps. These would be the set points for the station when the pumps are first put into operation. Adaptive control would then take over the determination of these transition points through the analysis of the actual kW input to the pumping station and adjust these set points to ensure minimum energy consumption.

Usually, with pump-down control, any set number of pumps is run to full speed before adding another pump on rising wet well level. This may cause much more energy consumption than with constant wet well level control. With constant wet well control, another pump is usually added long before the pumps reach full speed.

Pump and Wet Well Maintenance

Another advantage of constant wet well level control is the fact that the pumps are automatically programmed to operate as closely as possible to their best efficiency curve. This does not have a great effect on axial flow types such as vertical pumps, but it does have a pronounced effect on volute types, such as dry pit, single suction pumps. With this control, the pumps operate closely to the best efficiency curve where the radial thrust on the pump shafts is at a minimum. Such variable speed pumps, operating on this type of control, have run for years without replacing casing rings, impellers and sleeves. Also, reduced deflection at the seal faces extends seal life.

Experience with constant wet well control has demonstrated that sludge buildup on the walls occurs at one point on the side walls rather than across the whole area of the wall that is exposed as the pump level rises and falls with pump-down control.

One principal advantage of the open trench type wet well is its design for sludge removal. As indicated in Figure 3, the suction bell of the last pump in the well is located closer to the bottom to facilitate sludge removal. The open trench type wet well that is equipped with constant wet well control should be relatively free of maintenance.

Existing Sewage Lift Stations

When converting existing sewage pumps from constant to variable speed, constant wet well control should be reviewed to determine its value. Often, by increasing the wet well level, the capacity of the wet well is increased. Whether this is possible or not is dependent upon the incoming sewer configuration. If an existing wet well is considered for improvement of the pump operation or increased capacity, an energy input study should be made to determine the value of variable speed pump operation and constant wet well level control.

About the Author: James B. (Burt) Rishel is Owner and Manager of Pumping Solutions, LLC, a firm devoted to the evaluation of water systems and the development of variable speed pumping systems to achieve efficient pumping with reduced wear on centrifugal pumps. Former Chairman and CEO of Systecon Inc., he holds two U.S. patents on determination of pump head and programming of centrifugal pumps, and is the author of three books, 11 papers and over 40 articles. He consults extensively with Patterson Pump Company and Flo-Pak.