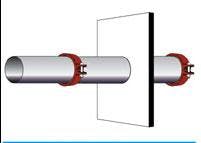

Convenient joint permits easy assembly and disassembly

Click here to enlarge imageThe system uses molded Halogenated Butyl flush gap gaskets specifically designed for the rough surface of ductile iron pipe and ideal for water service that can be used in temperatures ranging from -20° to 200°F. The gaskets respond to increasing pressure by increasing the sealing force to provide a leak-tight seal on the rough surface of ductile iron pipe.

Application Scenario

Among the many benefits of Gruvlok® piping in municipal water/wastewater treatment plant applications is faster and easier disassemblies, reinstallations and retrofits.

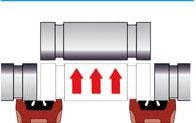

A common scenario in the wastewater industry is when a faulty pump needs to be fixed and is in a location that requires part of the piping system to be taken apart.

This often entails backing a winch truck or a crane into place in order to remove the existing pump and valves.

This process can cause extended downtime for the facility and result in expensive labor costs.

Gruvlok® piping, on the other hand, allows for fast disassembly without disturbing adjacent parts of the system. Quick access is realized via the removal of just two bolts on systems up to 12'' and only four bolts per joint on systems up to 20''.

There is never a need to wedge joints apart, and undamaged couplings, gaskets and fittings can be reused. In addition, the grooved piping method reduces fitting weight by as much as 30 percent.

The lighter system trims hoist requirements and can reduce manpower required for retrofit work and system maintenance.

Once maintenance or piping changes have been made the pipe and components can be reassembled. Since the grooved method does not require two-holing the joints, the reinstall is accomplished faster than traditional methods.

Pipe can be prepared for the grooved couplings either in the field or the shop. A simple adjustment to the pipe end groove makes any pipe connection rigid, or allows controlled axial movement and deflection to accommodate thermal expansion/contraction, ground settlement and seismic activity.

The couplings allow full 360° pipe rotation, which allows for infinite alignment opportunities — especially important for tees, laterals, valves and equipment.

It also allows for rotation of pipes to equalize internal wear.

Gruvlok® is backed by Anvil International, a manufacturer of pipe fittings, hangers and grooved piping products based in Portsmouth, NH. The company's lightweight grooving machine is available for sale or as a rental with a rent-to-own option.

More information on its grooved piping products is available at www.anvilintl.com.

The site contains downloadable specifications and an interactive submittal package.