Pressure Sewer System Applications, Design

By Chuck Stolberg, SWPA Executive Director

For more than 20 years, pressure sewer systems have been providing a cost-effective means of transporting sewage when compared to conventional gravity systems.

A pressure sewer system utilizes a pump at each sewer connection to transport wastewater to the collection and treatment system, hence the name "pressure sewer". These systems utilize a grinder pump which is a dual purpose device comprised of a cutter assembly, followed by a pumping element. The cutter assembly reduces sewage particulate to a slurry (1/2-in. or less solids), hence, the name "grinder". This allows the sewage to move freely through the passageways of the pump, small diameter pipeline and accessories, such as valves, to a dedicated treatment plant or any other required point of outflow.

Because pressure sewers are compatible with other collection system techniques, the advantages of each technology can be blended into site specific designs using grinder pumps, gravity, large submersible pumping stations and force mains to provide a complete solution to wastewater collection challenges.

Pressure sewer systems can serve a single building or a network of thousands of wastewater sources. They are especially cost-effective in challenging topographical areas where the soil is wet, rocky, or hilly, thus eliminating the need to dig deep or difficult gravity collection trenches.

Pressure sewers are one solution where: new construction build-out is slow, allowing pump stations to be added only as homes are built, reducing up front capital costs for developers; homes are spread far apart requiring deep gravity sewers; or septic systems have caused environmental problems due to overpopulation or failing leach fields.

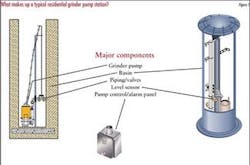

A grinder pump station typically consists of a grinder pump, sewage basin, controls and appropriate piping including an isolation valve and a check valve. The station is most commonly placed in the ground outside the building being served, so that the only visible sign of the station is its cover. However, in some instances the stations are designed to be located inside the building.

The sewage typically flows to the station via gravity and fills the sewage basin to a predetermined level at which time the grinder pump is activated.

The discharge piping connected to a residential station is typically 11/4'' or 11/2'' diameter pipe made of PVC or HD polyethylene installed in the ground just below the frost line using narrow trenchers or directional boring equipment. Strict vertical or horizontal alignment of piping is not required. Piping can be routed around natural or man-made obstacles with ease, meaning disruption to daily life in the area is generally minor. Multiple stations are connected to a force main typically consisting of 11/2'' to 8'' diameter pipe depending upon the number of stations and hydraulic conditions of the system.

The grinder pumps used in pressure sewer systems serving residential areas are typically produced in 1 and 2 HP sizes and consist of progressing cavity and centrifugal designs that operate at 1725 or 3450 RPM. The pumps generally operate on 240 volt, single-phase power which is supplied by the building being served. Energy cost for a single residence is approximately $3.00 per month.

Apartment buildings, schools, commercial, and light industrial applications connected to pressure sewers typically utilize submersible grinder pumps in a duplex configuration. The pumps can be rated 1 HP and up with a 11/4'' to 4'' discharge depending upon flow and head requirements. Typically the controls will alternate between pumps and allow both pumps to run simultaneously during abnormally high inflow conditions.

Extremely low operating and maintenance costs for pressure sewer systems have been documented from many successful systems, some of which have been in operation for more than 20 years. A successful pressure sewer system design uses the largest piping possible that achieves a cleansing velocity of at least 2 feet per second daily. By taking advantage of the experience these systems offer, a new system can be planned which will have good performance, high reliability and reasonable operating costs.

This information on grinder pumps in pressure sewers has been adapted from a Press Information Kit available electronically or in hard copy format upon request from the Submersible Wastewater Pump Association, 1866 Sheridan Road, Suite 201, Highland Park, IL 60035. Phone: 847-681-1868. FAX; 847-681-1869. E-Mail: [email protected].