Company's Rubber Valves Help Keep Water Flowing

The Red Valve Co. was founded in 1953 to develop a valve that would stand up to abrasive slurries in mining. Thus, an entirely new type of valve with a full-port opening and no moving parts was created, the Type A Pinch Valve. An engineered rubber sleeve is the only wetted part of the valve. The company's product line has evolved over the years, and it now offers a variety of valves for the water and wastewater industry.

The success of the Type A led to requests for other types of valves. Red Valve responded with a line of manually operated pinch valves that offered the same full-port opening and wear resistance, but with a standard ANSI B16.5 face-to-face dimension to replace ball, plug, and gate valves.

Next, the company developed a line of control valves and the concept of reduced-port sleeve trims to better match the valve to the conditions. Its patented Cone Sleeve remains the most popular sleeve trim for control applications.

Having solved most slurry handling problems, customers turned to Red Valve for a way to accurately measure pressure. The company developed the full-port, non-clogging pressure sensor, commonly called an "isolation ring". Several designs were developed, including a replacement for diaphragm seals and a tank level sensor.

In the early 1980's, the US Environmental Protection Agency asked Red Valve to create a valve that would replace metal flapgate check valves. The poor performance of these valves allowed water to backflow, requiring it to be re-treated, costing thousands of taxpayer's dollars annually. The request led to the company developing Tideflex®, a all-rubber check valve. The patented duckbill design opens with minimal pressure, operates with low headloss, and will not rust or corrode.

Mixing Systems

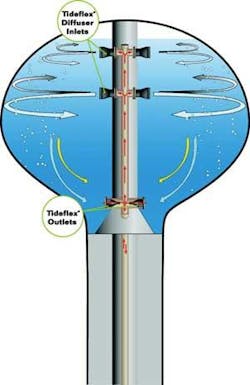

The Tideflex Mixing System (TMS) is the most recent application of the Tideflex design. The typical common inlet/outlet of many reservoirs often proves inadequate when water outside the common inlet/outlet area of influence becomes stagnant, creating dead spots where bacteria could multiply.

The TMS combines Tideflex check valves with a piping manifold that can be installed in new or existing water storage reservoirs of any shape and size to eliminate stagnation and short-circuiting. Operating on the differential pressure that is already in place, the TMS keeps energy costs low, while the all-elastomer construction of the check valve renders the system virtually maintenance free. A Tideflex check valve can also be used to protect the tank's overflow pipe from intrusion and tampering.

The backflow prevention capability of the Tideflex is used in effluent diffuser systems to prevent sand, silt, and marine growth from entering and clogging the outfall line. The duckbill shape of the valve increases jet velocity for better dispersion, and creates a plume for increased surface area.

The Tideflex principal has also been applied to air diffuser systems to overcome the clogging and tearing associated with traditional fine and coarse bubble designs. The valves have been incorporated into Red Valve air diffusers and air sparging nozzles to ensure peak performance under any conditions.

Red Valve's latest innovation is the Weirflex. When this special application valve is partially closed, it will allow for stormwater retention in the entire collection system piping. The weir action then permits a steady, controlled flow of wastewater to the treatment plant.

The company also produces expansion joints and rubber fittings. Its Redflex® line includes piping and ducting expansion joints, rubber fittings such as elbows and reducers, and rubber pipe. Red Valve can also customize rubber products.

The company has applied its rubber expertise to the Flexgate Slurry Knifegate Valve. The rugged and long lasting twin rubber seats of the Flexgate allow the sealing surfaces to be replaced when worn.