Importance of Membrane Integrity Testing

The growth in low-pressure membrane applications is largely attributed to the membrane’s physical barrier against particles and the subsequent high-log-removal efficiency that is achieved. Membrane fiber pores smaller than 0.1 micron can achieve total removal of pathogens, including Cryptosporidium muris and Giardia lamblia, which range in size from 3 to 10 microns. The removal efficiency, however, is directly correlated to fiber integrity. The method used to validate integrity must be sensitive enough to accurately and consistently detect a 3-micron defect. For this reason, on-line direct membrane integrity testing is vital to ensuring that the barrier and rejection is achieved.

A reliable method of direct integrity testing is critical in granting and validating high removal credits, especially for protozoa or viruses in membrane systems. The difficulty lies in how validation is accomplished. For example, the efficiency of conventional processes operating at log removal values (LRV) of 3 can be estimated from filtrate turbidity readings or particle count data. These methods do not always offer the required sensitivity for validating membrane processes that operate at greater than LRV 4. This was verified after extensive, deliberate membrane fiber cutting tests performed at the Memcor product installation in Kenosha, WI. These tests indicated that turbidity and particle count measurements gave an unambiguous response to fiber cutting only when the estimated results dropped to LRV 3.5.

Direct integrity testing using an air-pressure hold test was found to produce more accurate results and was therefore established as an in-situ, automated process for all Memcor products in the early 1990s.

Until recently, limited guidance was provided by the United States Environmental Protection Agency (USEPA) on the implementation and validation of membrane filtration. As a result, integrity testing protocols were approved on a case-by-case basis by U.S. states. The recent promulgation of the Long Term 2 Enhanced Surface Water Treatment Rule (LT2ESWTR) and the issuance of the accompanying Membrane Filtration Guidance Manual (MFGM) have provided a framework for regulating membrane systems. Today, the direct integrity test has provided the basis for the membrane industry.

Microbial Removal

USEPA recognizes membrane filtration in the Microbial Removal toolbox and in the MFGM, providing recommendations for incorporating direct integrity testing, as well as product-specific challenge testing, into a formal method for assessing membrane system log removal credits. EPA also makes numerous recommendations for preferred methods of conducting the pressure decay test.

The MFGM indicates several figures of merit for a pressure decay integrity test. These include:

• Resolution: The minimum pore size for which the test can detect leakage. The resolution of the test ultimately depends on the test pressure, as this determines which pore sizes are open for air flow.

• Sensitivity: The minimum leak rate that the test system can measure, which corresponds to the maximum LRV that the test can validate. The LRV resolution depends on: the accuracy of the pressure decay instrumentation; the ratio of the test volume to the membrane area being tested; and the relevant operating conditions of the plant (principally filtration flux and transmembrane pressure). Most resolutions of commercially available pressure decay test systems range from LRV 4.5 to 5.0 for typical plant operating conditions.

The MFGM provides several calculations for converting raw pressure decay data into equivalent log removal values. While the detail of several of these calculation procedures is quite daunting, the calculation is quite simple in principle. The pressure decay rate measured in the test can be converted to an air flow rate through the leakage path at test conditions. Based on the known physical properties of air and water, an “air/water conversation ratio” can be calculated to allow this air flow under test conditions to be converted to a water leakage flow under process conditions. The log removal value is then simply:

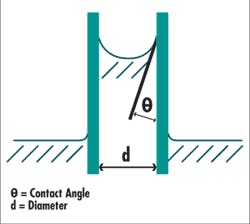

These calculations rely on several assumptions and data points that require careful review. For example, the test sensitivity calculation relies on knowledge of or an assumption about the contact angle of water with the pore wall. This is not an easy parameter to measure and is virtually impossible to measure in-situ on used membranes. Therefore, a conservative approach is to assume that the contact angle is zero (Figure 1), leading to the highest possible test pressure requirement for a given sensitivity.

The most commonly applied direct integrity test method is the air pressure hold test introduced by Memcor (Figure 2), in which the leakage of air from a closed volume at known pressure through a wetted membrane is measured and converted to an equivalent water leakage rate. The air leaks only through pathways representing large pore sizes, since the smaller pores remain wetted due to capillary forces. By selecting the appropriate test pressure, it is possible to measure the leak rate through only those pathways large enough to cause transmission of pathogenic protozoa.

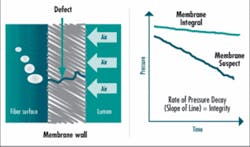

One of the most powerful aspects of direct integrity tests is their use in prompting scheduled maintenance of membrane modules in order to maintain a system above a required LRV value. Typically an upper control limit is established, resulting in remedial action (typically, leak identification and repair). A lower control limit is also defined, at which point the system is taken offline to allow for repairs to be completed. Control charts are used to allow maintenance to be scheduled, thus ensuring that system integrity remains within the pre-set control limits.

Key elements of overall integrity maintenance include the ability to identify and repair specific leak paths in membrane systems. Leak identification is usually done by sonic analysis, in which the sound of escaping air indicates the location of a leak path. Systems may be fitted with isolation valves that allow a single module or cluster of modules to be isolated from the flow path. This allows leaking modules to be isolated temporarily, pending permanent repair or replacement. Repair normally involves identifying the leaking fiber by air flow and then isolating that fiber permanently by sealing the ends with suitable pins to make sure it is removed from filtration. Thus, the process is commonly referred to as “pin repair”. Among the other methods of repair widely used in the industry is the process of “gluing” a fiber by injecting an epoxy into a membrane fiber.

Summary

Direct membrane integrity testing is an important process step to ensure that membrane filtration systems operate at high, validated removal efficiencies. The recently promulgated LT2ESWTR regulation and the guidance manual provide a logical basis for crediting membrane systems with high-log removal values for disease-causing microorganisms. The regulation also defines raw water quality ‘bins’ reflecting elevated risk of Cryptosporidium, and requires additional LRV for the higher risk bins. When subjected to an appropriate direct integrity test and product-specific challenge test, membrane filtration is recognized as a suitable method for achieving these higher LRV credits

About the Author:

Paul Gallagher, Ph.D., is director of process technology at Siemens Water Technologies, and is based in Sturbridge, Mass. He has 20 years of experience with membrane technologies, including product development, process design and engineering and pilot testing. Dr. Gallagher holds a B.E. in Chemical Engineering from the University College in Dublin, Ireland, and a Ph.D. in Chemical Engineering from the University of Notre Dame in Indiana. He has authored and co-authored several papers on membrane technology and can be reached at [email protected] or at 508-347-4644.