By Mike Snodgrass

All the water we have is all the water we will have. With serious drought and water scarcity issues throughout the U.S., the entire perception of water is changing at a rapid pace. The prospect of fresh water running out has been a sobering reality for many cities and communities, bringing reuse front and center to the water conversation. Once underappreciated and undervalued, water reuse is rapidly gaining acceptance whether it be for irrigation, groundwater recharge, or even potable reuse.

Membrane bioreactor (MBR) technology is well positioned to play a critical role in reuse applications, both domestically and internationally. Technological advances over the past 10 years have brought MBR costs down dramatically and no other wastewater treatment process is as efficient and effective. From retrofits to decentralized plants, MBRs are a versatile treatment platform that can help change perception and turn wastewater into a viable resource. When looking into advanced water reuse applications, MBRs represent the best overall investment a plant owner can make.

Technological developments and advancements have made MBRs both the best available technology (BAT) and investment for wastewater treatment and reuse. With a footprint 2-4 times smaller than conventional treatment processes and unmatched effluent quality, it has become difficult to argue against MBR. With 50 percent less unit operations, MBRs are less expensive to operate than conventional plants when tighter discharge limits are required.

Reuse applications, particularly potable reuse, require the highest level of treatment at an affordable cost in order to be viable. MBRs will play a critical role in advancing the reuse market as it is the most effective and cheapest technology to achieve today’s reuse quality standards. As reuse grows beyond the typical purple-pipe landscape irrigation application, higher and higher levels of treatment are needed. Only MBR is able to efficiently and effectively provide high removal rates of BOD, nutrients, and solids, all necessary for today’s reuse needs. In the case of potable reuse where reverse osmosis (RO) is employed, MBR also provides the ideal pre-treatment option.

Background

For decades, wastewater was simply viewed as a nuisance that was treated to minimal standards and discarded as quickly as possible. Due to increasing fresh water demand and decreasing supply, there has been an exceptional paradigm shift as wastewater has now become a viable and valuable resource. With new and growing demand for recycled water, treatment and technology requirements have also grown. Domestic wastewater is laden with organic material, nutrients, and microorganisms that must be removed in order to provide a safe and reliable water source. Conventional wastewater treatment technology, such as clarifiers and media filtration, was highly effective for decades but is now unable to meet such stringent water quality standards. Coupled with a large footprint, conventional treatment is quickly falling out of favor when it comes to advanced reuse applications where an exceptionally high effluent quality is a must.

When MBR technology was first developed and commercialized, the main economic driver was footprint as it was 2-4 times smaller than conventional treatment. Existing plants that needed to increase treatment capacity in the same footprint were a perfect fit for MBR retrofits. As the technology improved, both technically and economically, the demand for MBRs has grown significantly. The ability to achieve ultra-low BOD and nutrient levels while achieving high levels of disinfection, opened new doors for MBR technology. It is difficult to come across a wastewater treatment project, whether a Greenfield or plant retrofit, where MBR is not being considered or evaluated.

MBR Treatment Efficiency

A key difference between conventional activated sludge (CAS) processes and MBR is footprint. Since CAS systems rely on clarifiers to remove solids, they are limited in the biomass concentrations in the bioreactors. The use of a membrane barrier layer to remove solids allows decoupling of a plant’s hydraulic and solids retention time (HRT and SRT). Therefore, MBRs can be operated at much higher mixed liquor suspended solids (MLSS) concentrations, shrinking plant footprint dramatically. The combination of highest effluent quality, smallest footprint, and lowest life cycle costs has made MBR the best available technology for today’s reuse projects.

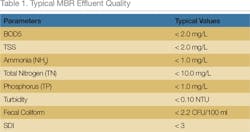

Unlike a CAS treatment process that relies on sedimentation for solids separation, MBRs provide a definitive boundary layer that provides complete solids retention. Membranes used in MBR systems contain microscopic pores that are significantly smaller than many pathogens and microorganisms, meaning a high level of disinfection can be achieved with just an MBR. Both solids and pathogens are retained by the membrane, providing a highly disinfected, low turbidity effluent (see Table 1).

Decentralized Treatment

Decentralized wastewater treatment, often referred to as “scalping,” is gaining in popularity because it takes a nuisance (waste biosolids) and turns it into a resource (reuse quality effluent) directly at the point of use. As water reuse practices continue to grow, industry experts and practitioners are also beginning to see that centralized treatment is not always practical or cost effective. The cost to install pipelines that carry recycled water from a centralized treatment plant to the point of use can far exceed the cost of a satellite treatment plant. MBR technology is particularly well suited for scalping plants due to its compact footprint and high-quality effluent. Advances in MBR technology over the past 10-15 years have positively impacted capital and operating economics. In today’s water industry, MBR is cost competitive, if not cheaper, than conventional treatment approaches such as sequencing batch reactors (SBR) or CAS.

Potable Reuse

Once unfairly and unjustly described as “toilet to tap,” potable reuse had significant political and public perception hurdles to overcome but has now broken through some significant barriers. Parched and water-starved states such as California and Texas have come to the realization that potable reuse must become part of their respective drinking water portfolios. As lush lawns quickly turned brown due to historic droughts, public perception began to shift. Potable reuse really isn’t a new concept: Mother Nature has been doing it forever. MBRs do the same thing but at a much more efficient and rapid pace.

All potable reuse projects require RO as part of the treatment process. RO membranes are particularly sensitive to particulate matter, organic material, and microbial activity, so a high level of pre-treatment is required. The standard used in the RO industry for inlet quality is the silt density index (SDI), and MBR effluent is proven to have excellent values, something conventional treatment would struggle to achieve. In the case of Greenfield projects, MBRs are an obvious choice for potable reuse projects due to lower total installed costs and footprint but they are also particularly well suited for retrofit of existing plants looking to implement potable reuse.

Traditionally, potable reuse projects have employed a tertiary ultrafiltration (UF)/microfiltration (MF) filter downstream of the secondary clarifiers in a conventional WWTP. While this approach may realize lower upfront equipment costs, it adds to the overall system complexity and physical size. Operators are now tasked with running and maintaining a conventional activated sludge process and a UF/MF system. By integrating a UF/MF membrane into the biological process, both overall unit operations and footprint are reduced by 50 percent (or more).

Ongoing projects, such as Big Spring, Texas, have seen the quality of their drinking water supply improve with the introduction of potable reuse into their supply systems. With potable reuse, whether direct or indirect, the treatment requirements are so intensive that resulting water quality far exceeds traditional drinking water supplies. It’s hard to argue against potable reuse.

Summary

MBRs are drastically changing not only how we view water but also how we treat and manage it. The treatment capability of an MBR will quickly drive it to the forefront of the wastewater treatment industry. No other technology can provide the same level of treatment in the same, small footprint and at the same, small cost. Water sustainability will help drive economies and provide communities with a reliable and dependable water supply. MBRs will undoubtedly play a critical role in advancing such sustainability goals.

About the Author: Mike Snodgrass is the Membrane Technology Leader for the Ovivo MBR Systems Group, where he is responsible for the development and integration of new membrane technologies for use in membrane bioreactor systems (MBRs). He has spent his entire 16-year professional career in the membrane industry with positions held in R&D, sales & marketing, manufacturing, and field/technical support.